Philbert

Chainsaw Enthusiast

- Local time

- 2:29 PM

- User ID

- 737

- Joined

- Jan 30, 2016

- Messages

- 5,049

- Reaction score

- 21,631

- Location

- East Dakota

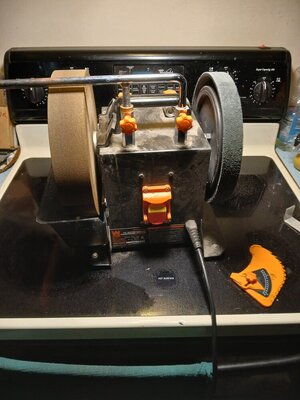

Anyone have, or use, a Tormek, wet sharpener?

Or the JET, or one of the other versions?

Interested in your experiences; comparisons between the different makes and models; and which guides are most useful (knives, chisels, plane blades, etc.).

Also, any advice on what to watch out for, if buying a used one.

Thanks!

(Photo of new, T8 for illustration.)

Philbert

Or the JET, or one of the other versions?

Interested in your experiences; comparisons between the different makes and models; and which guides are most useful (knives, chisels, plane blades, etc.).

Also, any advice on what to watch out for, if buying a used one.

Thanks!

(Photo of new, T8 for illustration.)

Philbert

Last edited: