junkman

Crush it

- Local time

- 8:05 PM

- User ID

- 388

- Joined

- Jan 3, 2016

- Messages

- 4,312

- Reaction score

- 17,051

- Location

- pacific northwest

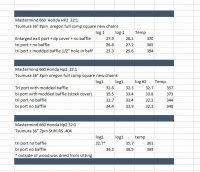

Just what I have experienced milling,I messed with mufflers more to reduce sound than was looking for power, I had to retune between stock, stock with dual port cover and gutted dual port. When doing this milling I can feel the pull in the cut difference, the top rpms drop also when start restricting over the gutted muffler tune, I never recorded times I am just posting what I experienced, another saw doing different work may get different results. I also did try a baffled muffler in my 461 I lost roughly 3 seconds roughly in a 30 second cut over the gutted one cutting a 30 inch dough fir cookiewell they all seemed pretty "optimally tuned" to me ...but with out one of you masters here to give my tune your blessing then we'll just never know for sure will we.

for the record - I had Treemonkey check my tune on the saw and he said I tuned it good.

I am done testing mufflers.

you keep saying this but where are the numbers???