cease232

Pinnacle OPE Member

- Local time

- 7:07 PM

- User ID

- 1443

- Joined

- Jun 20, 2016

- Messages

- 524

- Reaction score

- 1,733

- Location

- Montana

Disclaimer- Title is a little misleading because I used a wood lathe.

I had to step away from saws for a minute to spend money on other things. Well I was visiting family in New Mexico and my cousin had an 044 sitting out in his field. It was sun bleached white and covered in powdery sawdust. Could start but wouldn’t stay running. Offered to fix it but he said I could have it. I paid him a fair price and shipped the saw home to Oregon. Once I tore into it I found a pretty low hour saw that had been neglected. Probably ran lightly for a few seasons and when it stopped working was tossed aside. Well since I had it apart and needed an excuse to procrastinate other projects I decided to experiment.

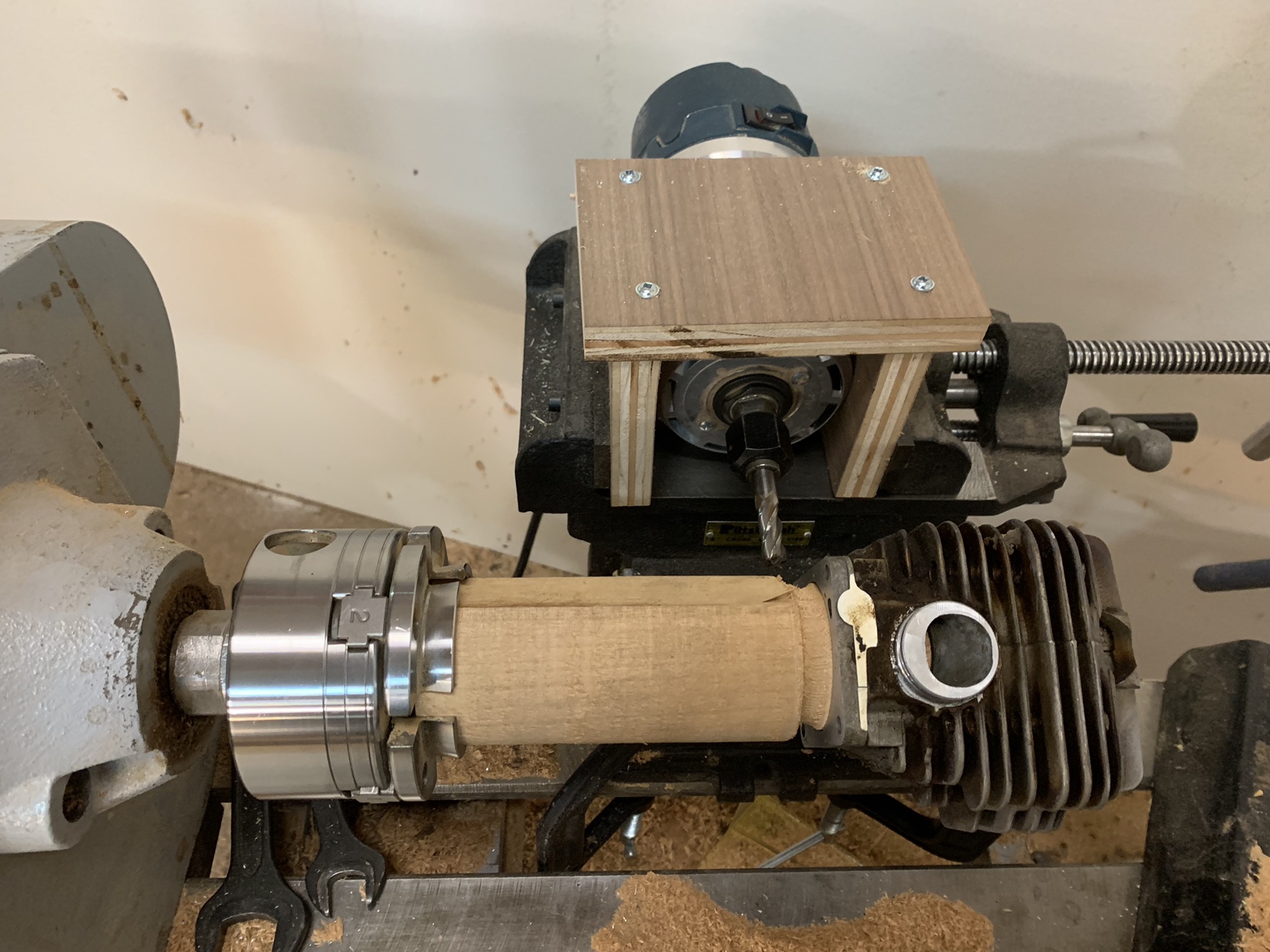

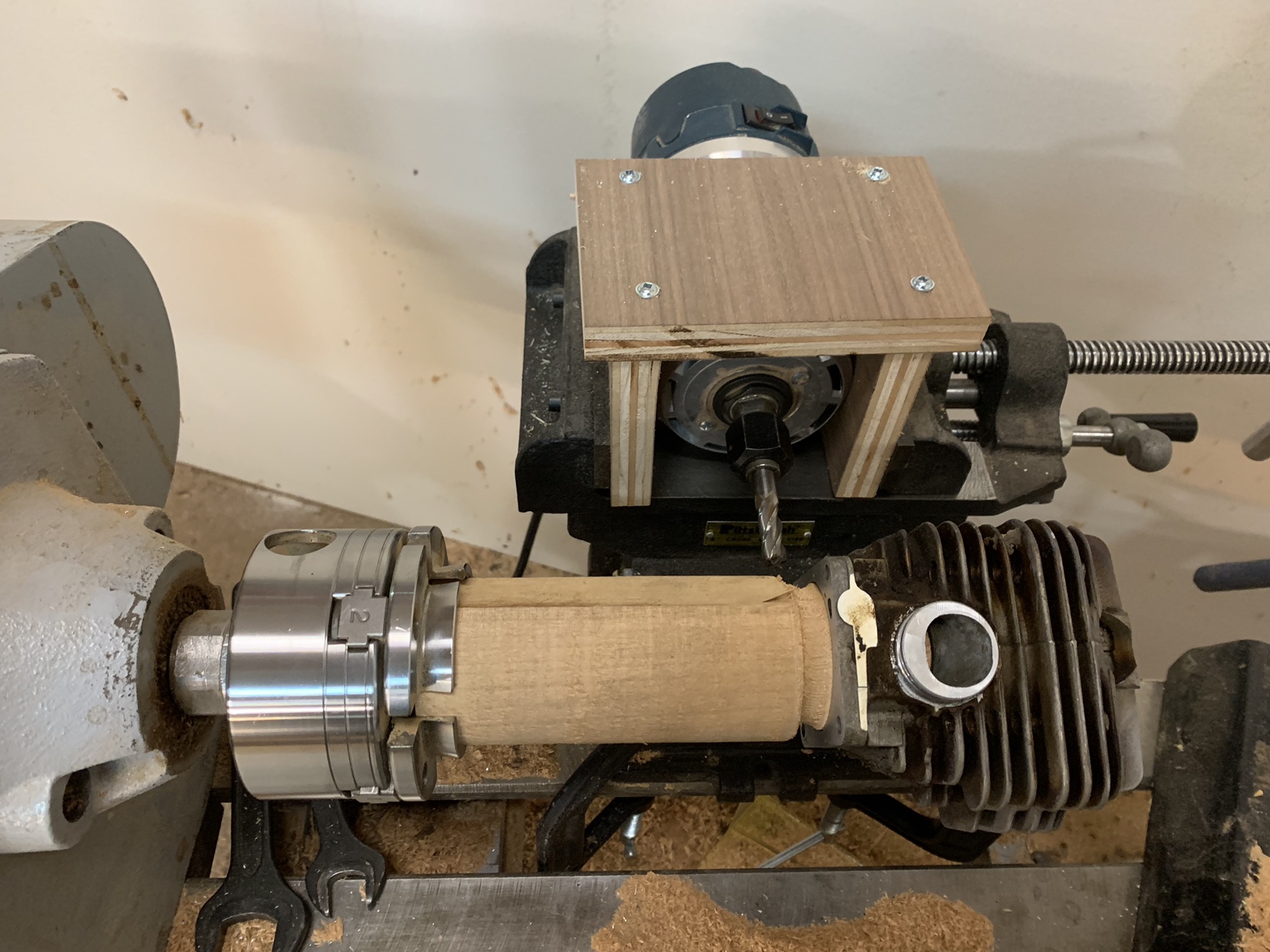

I recently bought a cross vise at a yard sale for 10$. I clamped the vise to the bed of my wood lathe and clamped a router into the cross vise. Turned down a piece of alder to 50mm and mounted up the cylinder. Chucked a 3/8 endmill into my router and thats it.

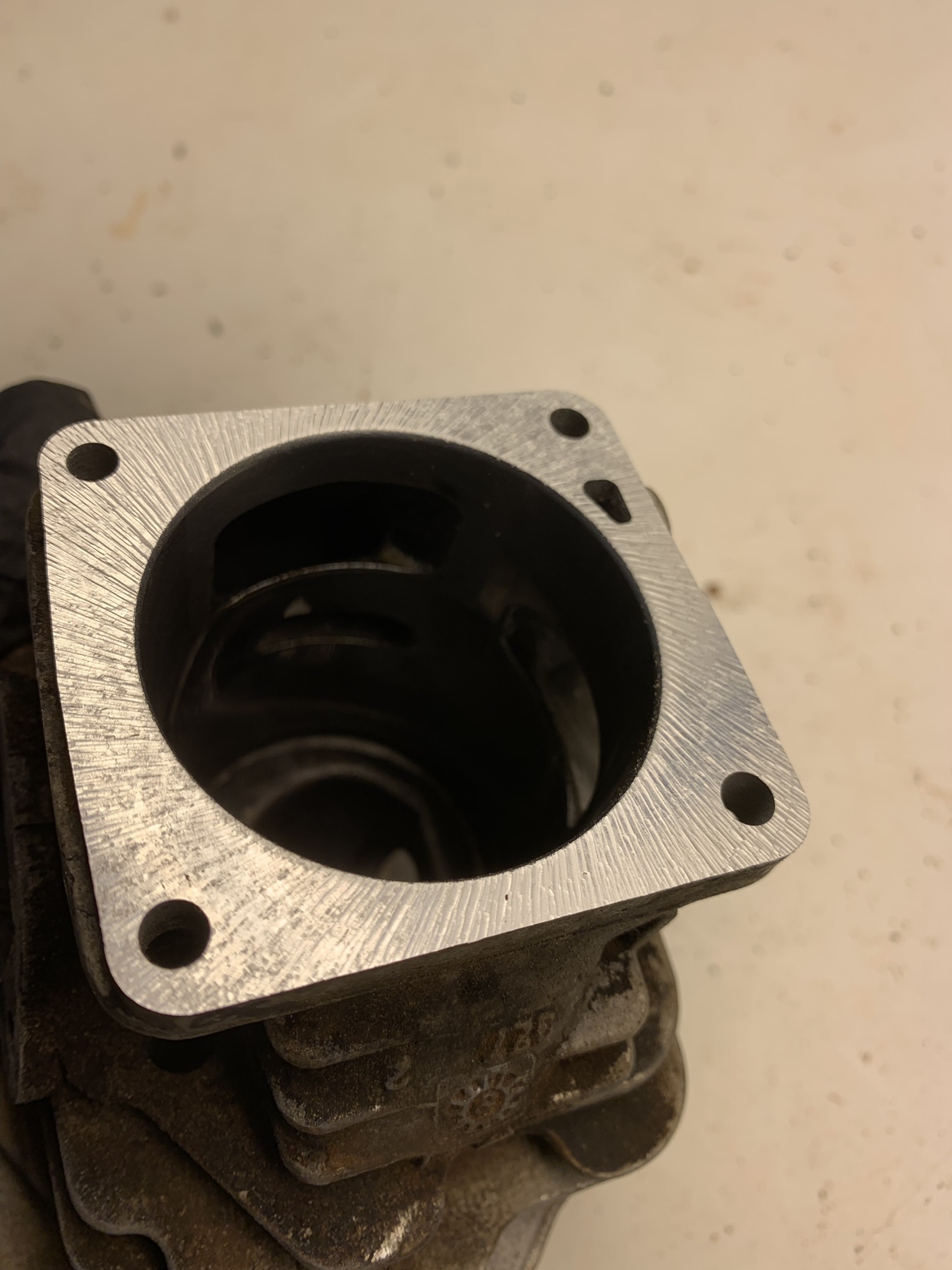

Squish was right about .030 so I was shooting for removing .010

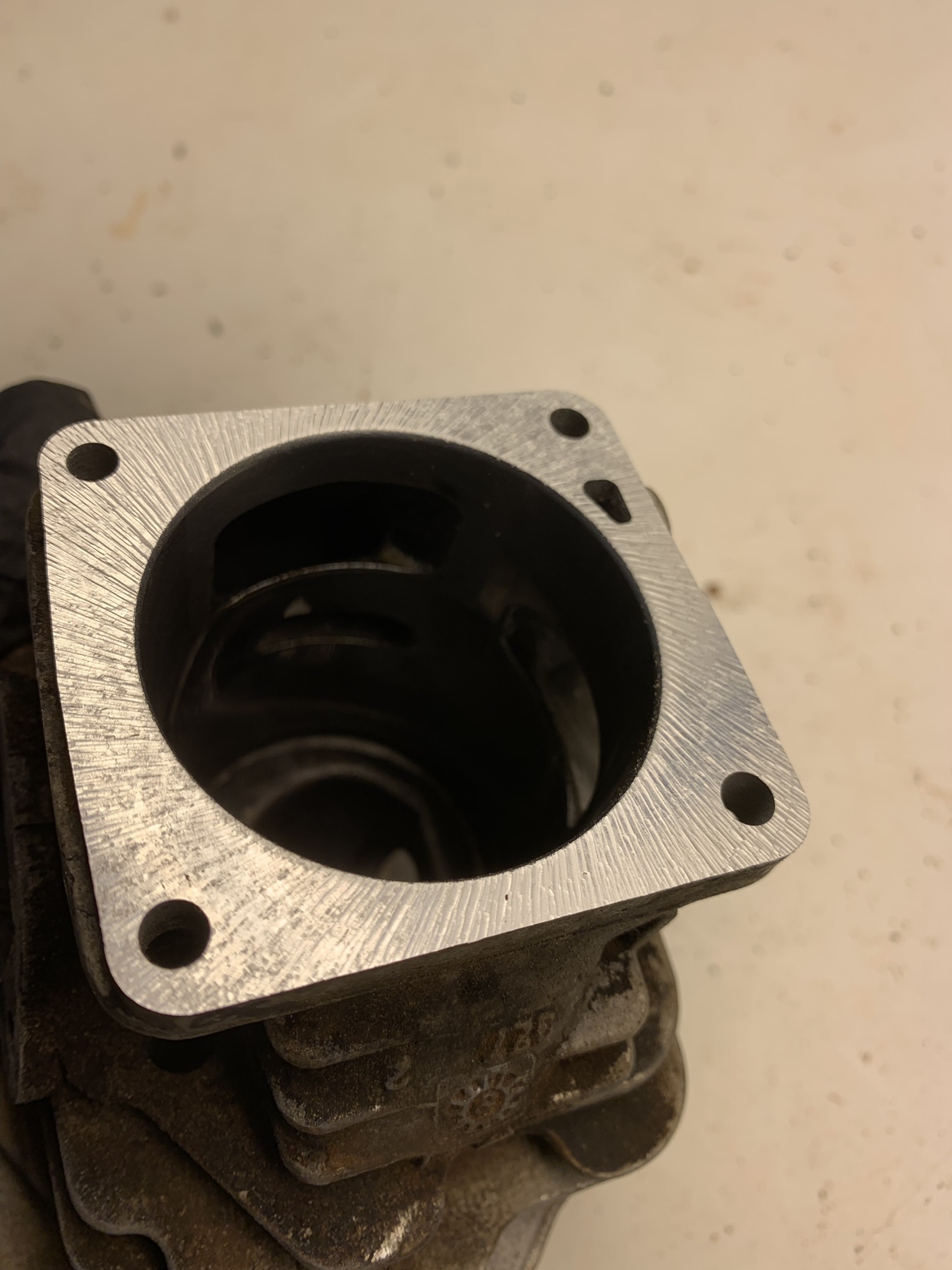

Finish looked pretty rough but a couple spins on a sheet of 220 grit sand paper on a cast iron surface and it turned out pretty nice.

Squish ended up dead on .020 on both sides of the piston.

Thanks for reading. Some of you may remember my other thread.

http://opeforum.com/threads/machining-base-without-a-lathe.3989/

Jeremiah.

I had to step away from saws for a minute to spend money on other things. Well I was visiting family in New Mexico and my cousin had an 044 sitting out in his field. It was sun bleached white and covered in powdery sawdust. Could start but wouldn’t stay running. Offered to fix it but he said I could have it. I paid him a fair price and shipped the saw home to Oregon. Once I tore into it I found a pretty low hour saw that had been neglected. Probably ran lightly for a few seasons and when it stopped working was tossed aside. Well since I had it apart and needed an excuse to procrastinate other projects I decided to experiment.

I recently bought a cross vise at a yard sale for 10$. I clamped the vise to the bed of my wood lathe and clamped a router into the cross vise. Turned down a piece of alder to 50mm and mounted up the cylinder. Chucked a 3/8 endmill into my router and thats it.

Squish was right about .030 so I was shooting for removing .010

Finish looked pretty rough but a couple spins on a sheet of 220 grit sand paper on a cast iron surface and it turned out pretty nice.

Squish ended up dead on .020 on both sides of the piston.

Thanks for reading. Some of you may remember my other thread.

http://opeforum.com/threads/machining-base-without-a-lathe.3989/

Jeremiah.