toolmaker

Super OPE Member

- Local time

- 9:23 AM

- User ID

- 11603

- Joined

- Jan 31, 2020

- Messages

- 289

- Reaction score

- 578

- Location

- Tyrone, Pa

I have been sharpening landing saw chains for a logger in a trailer set up at the landing for a repair shop.

Using an Oregon chain grinder and a new diamond 5/16 semi round wheel.

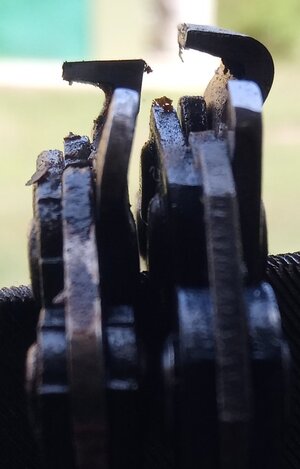

Don't know what size the chains are, but the cutters are huge compared to my 3/8-.050"-84 DL chains for my built 462C.

The landing saw chains have 96 drivers, I think they are about 5' long.

I can get pics if needed.

I'm having a problem:

When a chain is in the grinder and taking in consideration of the rotation of the wheel, there is a side that we would call grinding from inside out (left-hand cutter), and a side that we would call grinding from outside in (right-hand cutter).

The RH cutters grind up very nicely because the wheel rotation pushes the burr to the inside and not toward the cutting edge.

I have a LOT of trouble with the LH cutters because the wheel rotation pushes the burr to the outside of the cutter and it hangs on to the cutting edge.

The only way I can see to cure this is to reverse the direction of the motor rotation so that the LH cutters are also cutting from outside in; or, find a way to flip the chain around so it would be cutting from outside in.

Yes, I have tried everything I can think of to try and reduce the burr. Dressing the wheel, light cuts, heavy cut, slow down feed on motor, fast down feed on motor, rough pass then light finish pass, non-diamond wheels, you name it, I tried it...................................

Still getting a burr on LH cutters.

I am certain someone else has seen this also.

Ideas?

Thanks guys.........

Using an Oregon chain grinder and a new diamond 5/16 semi round wheel.

Don't know what size the chains are, but the cutters are huge compared to my 3/8-.050"-84 DL chains for my built 462C.

The landing saw chains have 96 drivers, I think they are about 5' long.

I can get pics if needed.

I'm having a problem:

When a chain is in the grinder and taking in consideration of the rotation of the wheel, there is a side that we would call grinding from inside out (left-hand cutter), and a side that we would call grinding from outside in (right-hand cutter).

The RH cutters grind up very nicely because the wheel rotation pushes the burr to the inside and not toward the cutting edge.

I have a LOT of trouble with the LH cutters because the wheel rotation pushes the burr to the outside of the cutter and it hangs on to the cutting edge.

The only way I can see to cure this is to reverse the direction of the motor rotation so that the LH cutters are also cutting from outside in; or, find a way to flip the chain around so it would be cutting from outside in.

Yes, I have tried everything I can think of to try and reduce the burr. Dressing the wheel, light cuts, heavy cut, slow down feed on motor, fast down feed on motor, rough pass then light finish pass, non-diamond wheels, you name it, I tried it...................................

Still getting a burr on LH cutters.

I am certain someone else has seen this also.

Ideas?

Thanks guys.........