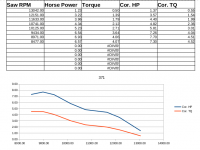

What does your scale read wide open with no load? Maybe you need to add that into your calculations? Might bring your numbers closer to "normal".

Unless it is an easy conversion factor, and it repeats among lots of saws. Your dyno may just real low, and that is fine. Test a saw stock and then again after mods and it will show the gains.

Which is what a dyno is made for. Show the difference.

Unless it is an easy conversion factor, and it repeats among lots of saws. Your dyno may just real low, and that is fine. Test a saw stock and then again after mods and it will show the gains.

Which is what a dyno is made for. Show the difference.