You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Dolmar 64xx/73xx/79xx series, smurfs and solo 665/675/681 thread

- Thread starter huskyboy

- Start date

Backtroller

Here For The Long Haul!

- Local time

- 7:56 PM

- User ID

- 349

- Joined

- Dec 31, 2015

- Messages

- 2,794

- Reaction score

- 11,349

- Location

- Land of Badgers

Mine is a 2012 and leaks a little

- Local time

- 3:56 AM

- User ID

- 1204

- Joined

- Apr 28, 2016

- Messages

- 14,903

- Reaction score

- 59,251

- Location

- Croatia

That’s great to know, I’m guessing mine doesn’t have the green one, it’s a first or second year production saw. I’ll have to pm you.

Green should be the old style and black the updated one.I'm not sure if green is the old one or new either. Found a bunch on eBay at a good price and bought them. 5, 6, 8...I'm not sure how many there are. All new

My PS-7300 was leaking, she had the green line.

The leak was caused by the line not pressing sufficiently against the pump.

She doesn't leak no more since I replaced the line, she's always sitting on the shelf with full tanks.

I could be wrong though.

I'd have to check the pictures I took and PM's I had with Nate (fordf150).

- Local time

- 8:56 PM

- User ID

- 360

- Joined

- Dec 31, 2015

- Messages

- 23,530

- Reaction score

- 150,470

- Location

- East Jordan, MI

I think you're right. But I replaced mine with a green one and it quit leaking. So I'm good with itGreen should be the old style and black the updated one.

My PS-7300 was leaking, she had the green line.

The leak was caused by the line not pressing sufficiently against the pump.

She doesn't leak no more since I replaced the line, she's always sitting on the shelf with full tanks.

I could be wrong though.

I'd have to check the pictures I took and PM's I had with Nate (fordf150).

- Local time

- 3:56 AM

- User ID

- 1204

- Joined

- Apr 28, 2016

- Messages

- 14,903

- Reaction score

- 59,251

- Location

- Croatia

I didn't want to imply that there is anything wrong with the green lines, apologies if it sounded like I did.I think you're right. But I replaced mine with a green one and it quit leaking. So I'm good with it

I am sure a new green line will fix oil leakage as well as a black line.

I just ordered new suction and pressure lines for my PS-7300 and received black ones, if they had been green I would have implemented them with full confidence.

I am pretty certain that my PS-6400 & PS-7900 both feature green lines them being early production saws, never had a leakage problem with either.

Last edited:

Deets066

AKA Deetsey

- Local time

- 8:56 PM

- User ID

- 290

- Joined

- Dec 28, 2015

- Messages

- 15,443

- Reaction score

- 73,596

- Location

- Illinois

My guess is composition is the same, just the color difference to designated the updated hose. Most likely just a different size tolerance or molded a fuzz differentAnyone know what the difference is between the green and black hose?

huskyboy

Sorta a husqvarna guy...

- Local time

- 8:56 PM

- User ID

- 1352

- Joined

- May 30, 2016

- Messages

- 10,026

- Reaction score

- 43,488

- Location

- Ct

Oil line may be different, but I like the improved black fuel line compared to the old green one. The fuel filter fits more snugly on the end and the line doesn’t seem to kink as easily between the tank and carb box. Fuel line install has to be one of the easiest of any saw. Tank off (which is easy compared to a 046 or 372), then feed the line through the hole from inside the tank, pull it through. As you are installing the tank, pull it through carb box hole. Done.

- Local time

- 4:56 AM

- User ID

- 5546

- Joined

- Mar 8, 2018

- Messages

- 6,204

- Reaction score

- 47,435

- Location

- Evia, Greece

Oil line may be different, but I like the improved black fuel line compared to the old green one. The fuel filter fits more snugly on the end and the line doesn’t seem to kink as easily between the tank and carb box. Fuel line install has to be one of the easiest of any saw. Tank off (which is easy compared to a 046 or 372), then feed the line through the hole from inside the tank, pull it through. As you are installing the tank, pull it through carb box hole. Done. View attachment 138821View attachment 138822

Ya'll quit playin' with your hoses...

dahmer

Here For The Long Haul!

- Local time

- 8:56 PM

- User ID

- 3987

- Joined

- Sep 6, 2017

- Messages

- 2,524

- Reaction score

- 10,105

- Location

- Ellwood City, PA

Green hoses are proof that aliens exist.Ya'll quit playin' with your hoses...

Lightning Performance

Here For The Long Haul!

- Local time

- 8:56 PM

- User ID

- 677

- Joined

- Jan 26, 2016

- Messages

- 10,991

- Reaction score

- 28,059

- Location

- East of Philly

Buncha hosers A??

- Local time

- 3:56 AM

- User ID

- 1204

- Joined

- Apr 28, 2016

- Messages

- 14,903

- Reaction score

- 59,251

- Location

- Croatia

Dolmar PS-6400 starter assembly sticker, part number 980 115 674

Dolmar PS-7300 starter assembly sticker, part number 980 115 679

Dolmar PS-7310 starter assembly sticker, part number 980 115 706

Dolmar PS-7900 starter assembly sticker, part number 980 115 672

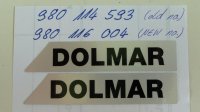

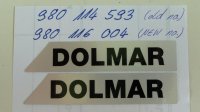

Dolmar PS-64xx/73xx/79xx clutch cover sticker, old part number 980 114 593 , new part number 980 116 004

Dolmar PS-7910 starter assembly sticker, part number 980 115 705 - sorry, no picture (yet)

Dolmar PS-7300 starter assembly sticker, part number 980 115 679

Dolmar PS-7310 starter assembly sticker, part number 980 115 706

Dolmar PS-7900 starter assembly sticker, part number 980 115 672

Dolmar PS-64xx/73xx/79xx clutch cover sticker, old part number 980 114 593 , new part number 980 116 004

Dolmar PS-7910 starter assembly sticker, part number 980 115 705 - sorry, no picture (yet)

huskyboy

Sorta a husqvarna guy...

- Local time

- 8:56 PM

- User ID

- 1352

- Joined

- May 30, 2016

- Messages

- 10,026

- Reaction score

- 43,488

- Location

- Ct

Had a heck of a time figuring out why the 7900 wasn’t returning to idle, made setting the jets harder than usual (kind of like a worn out clutch would do). I first replaced the throttle cable with a new one and inspected the entire trigger assembly, worked a little better. However I could tell it still wasn’t quite right. I did some further investigation and discovered the throttle cable holder on the carb was cut too long on the seat. Which held the cable off the idle screw just enough to f with the settings. I took a small drill bit and razor and removed just enough material from the seat (it wasn’t easy, hard to get at and remove too much and you won’t get full throttle). Problem solved. Screwdriver is pointed at the part I had to modify.

Screwdriver is pointed at the part I had to modify.  These are the tools I used. A small dremel burr would work too.

These are the tools I used. A small dremel burr would work too.

Screwdriver is pointed at the part I had to modify.

Screwdriver is pointed at the part I had to modify.  These are the tools I used. A small dremel burr would work too.

These are the tools I used. A small dremel burr would work too.Simondo

Here For The Long Haul!

Mason. Was there no free play on the trigger at all ?Had a heck of a time figuring out why the 7900 wasn’t returning to idle, made setting the jets harder than usual (kind of like a worn out clutch would do). I first replaced the throttle cable with a new one and inspected the entire trigger assembly, worked a little better. However I could tell it still wasn’t quite right. I did some further investigation and discovered the throttle cable holder on the carb was cut too long on the seat. Which held the cable off the idle screw just enough to f with the settings. I took a small drill bit and razor and removed just enough material from the seat (it wasn’t easy, hard to get at and remove too much and you won’t get full throttle). Problem solved.View attachment 139277Screwdriver is pointed at the part I had to modify. View attachment 139279 These are the tools I used. A small dremel burr would work too.

huskyboy

Sorta a husqvarna guy...

- Local time

- 8:56 PM

- User ID

- 1352

- Joined

- May 30, 2016

- Messages

- 10,026

- Reaction score

- 43,488

- Location

- Ct

No, saw is extremely low hour. Most likely a defective throttle cable holder or sheath cut incorrect length on the cable I’m guessing.Mason. Was there no free play on the trigger at all ?

Simondo

Here For The Long Haul!

Think it could very well have been the cable shroud. I had a cable shroud that seemed a tiny bit long on a saw once ....shortening a tiny bit solved the lack of free play .No, saw is extremely low hour. Most likely a defective throttle cable holder or sheath cut incorrect length on the cable I’m guessing.

huskyboy

Sorta a husqvarna guy...

- Local time

- 8:56 PM

- User ID

- 1352

- Joined

- May 30, 2016

- Messages

- 10,026

- Reaction score

- 43,488

- Location

- Ct

This definitely isn’t the first saw I had to play around with the throttle cable setup. Throttle wires as well I had to bend to optimum length. Not too difficult, but it can drive ya nuts if you don’t know what to look for.Think it could very well have been the cable shroud. I had a cable shroud that seemed a tiny bit long on a saw once ....shortening a tiny bit solved the lack of free play .

- Local time

- 1:56 AM

- User ID

- 685

- Joined

- Jan 26, 2016

- Messages

- 7,844

- Reaction score

- 37,653

- Location

- South west UK

I’ve watched that one several times on youtube

mdavlee

Hillbilly grinder

- Local time

- 8:56 PM

- User ID

- 279

- Joined

- Dec 28, 2015

- Messages

- 14,194

- Reaction score

- 64,634

- Location

- TN

FYI to run a 8-9 pin on these the dust flap in clutch cover needs modified to clear the chain. At least on mine it did. Easy to do and doesn’t affect the functionality. I think this may only be on the early saws. Maybe they’ve changed it on later ones?

I put chain on 9 pin and started it. Clearances itself[emoji23]