cease232

Pinnacle OPE Member

- Local time

- 8:37 PM

- User ID

- 1443

- Joined

- Jun 20, 2016

- Messages

- 524

- Reaction score

- 1,739

- Location

- Montana

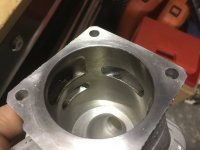

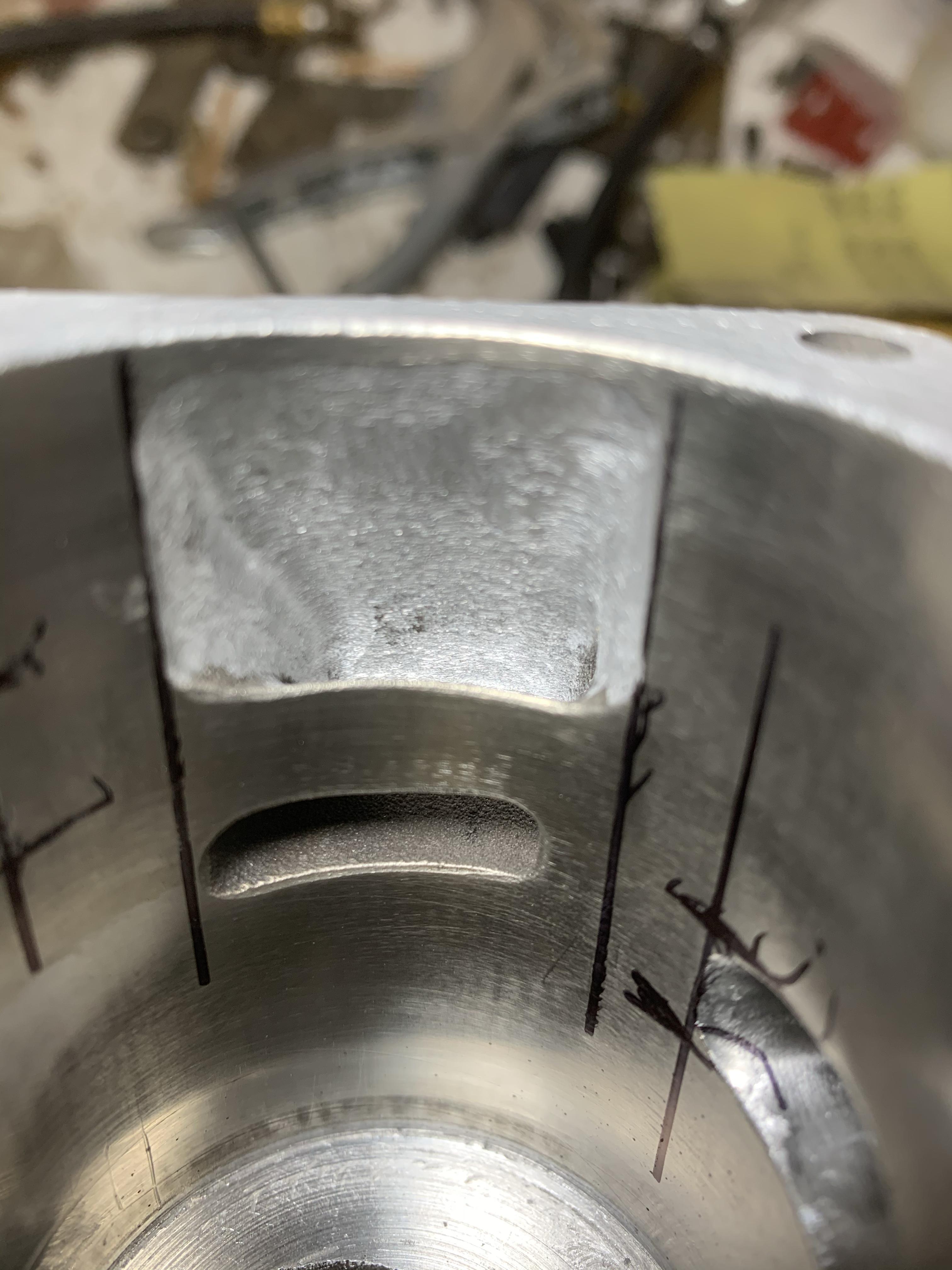

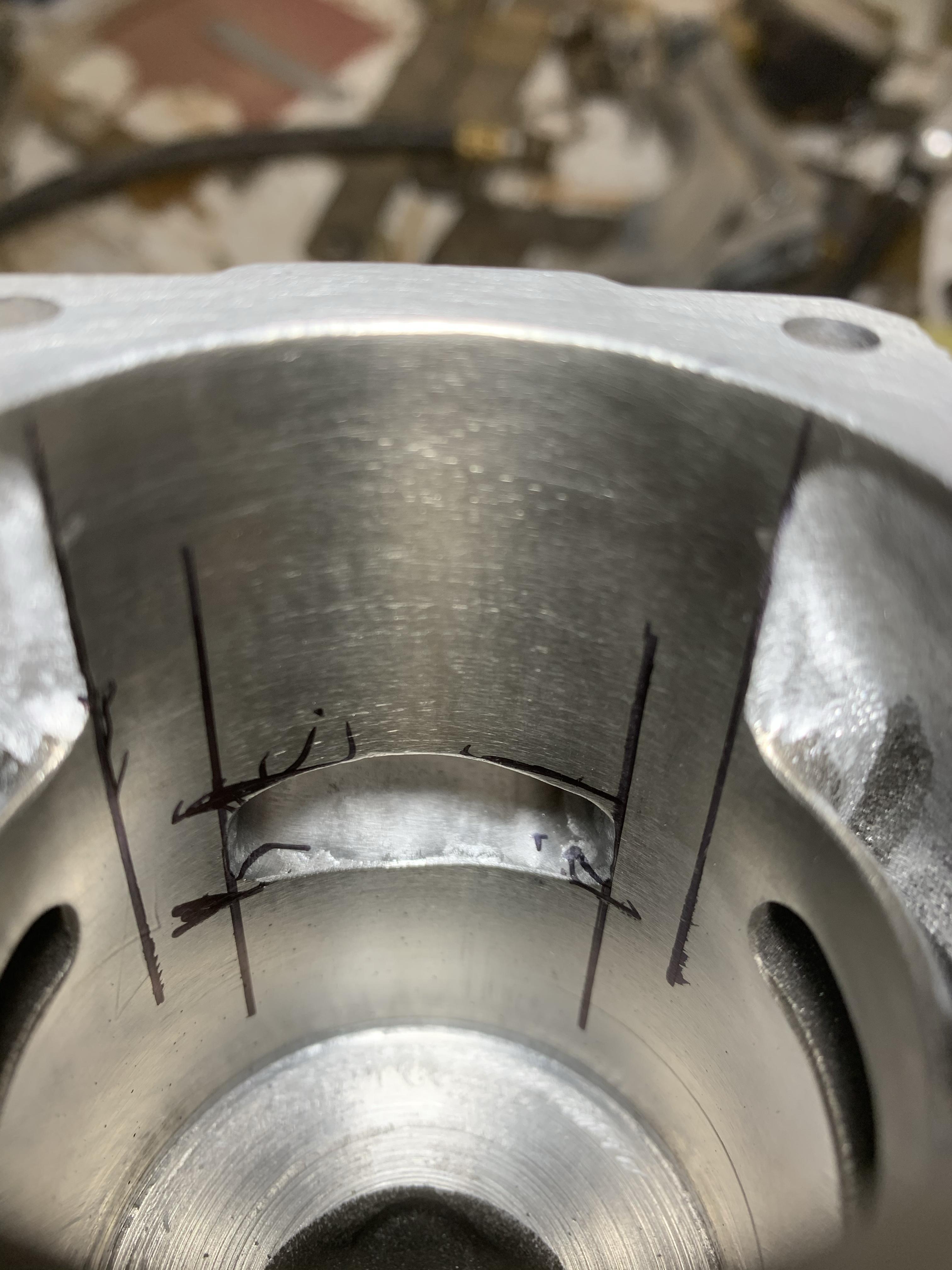

Took a break from chainsaw forums and tinkering. Still use saws everyday but had too many other things going on to play with them. Bought myself a new ms461 last week and got the bug again. Had this 026 I bought a couple years ago still on my bench. Top end was lightly scored so I decided to do some grinding.

Took .053 off the base

Set the squish with an OEM gasket

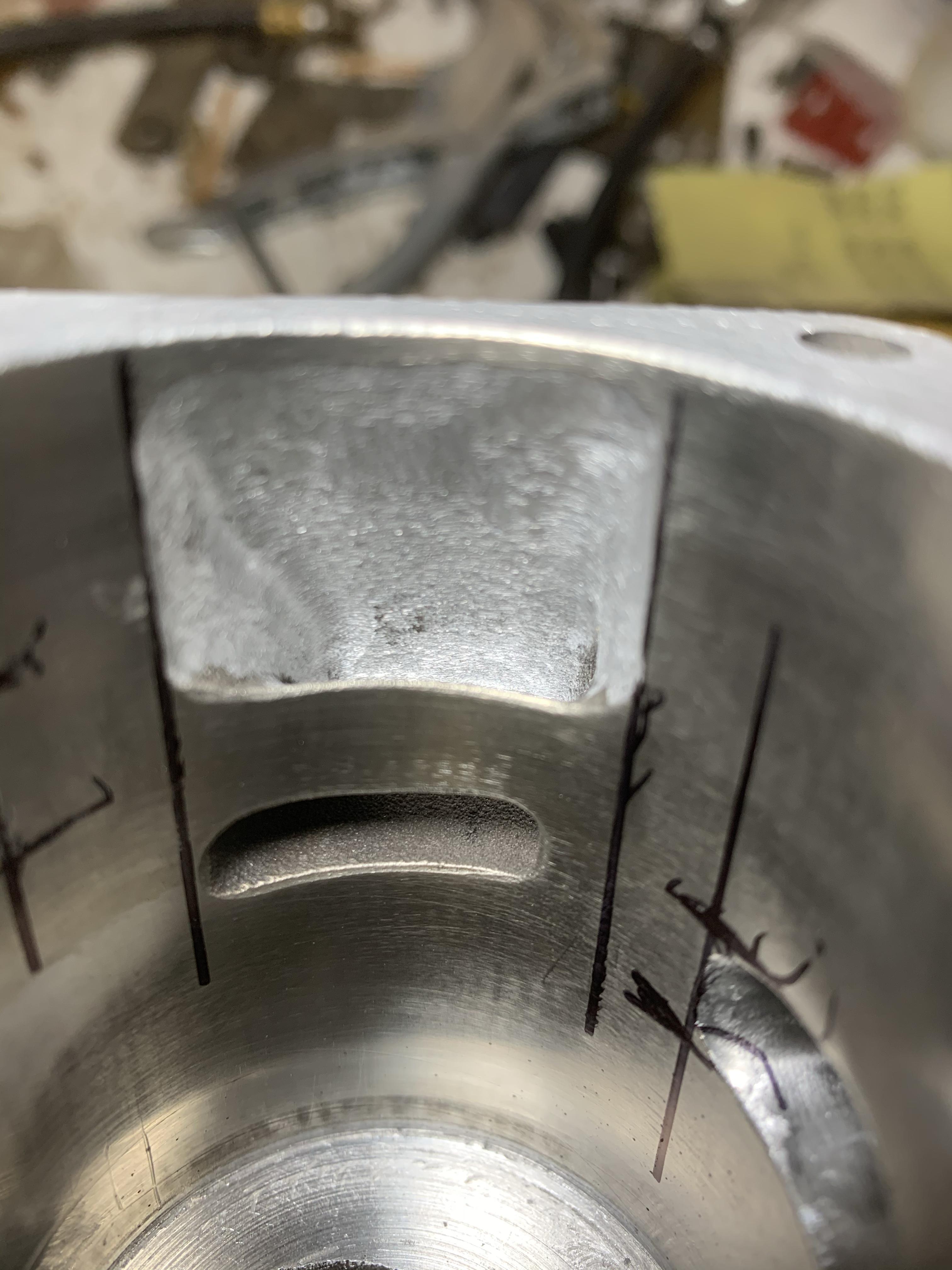

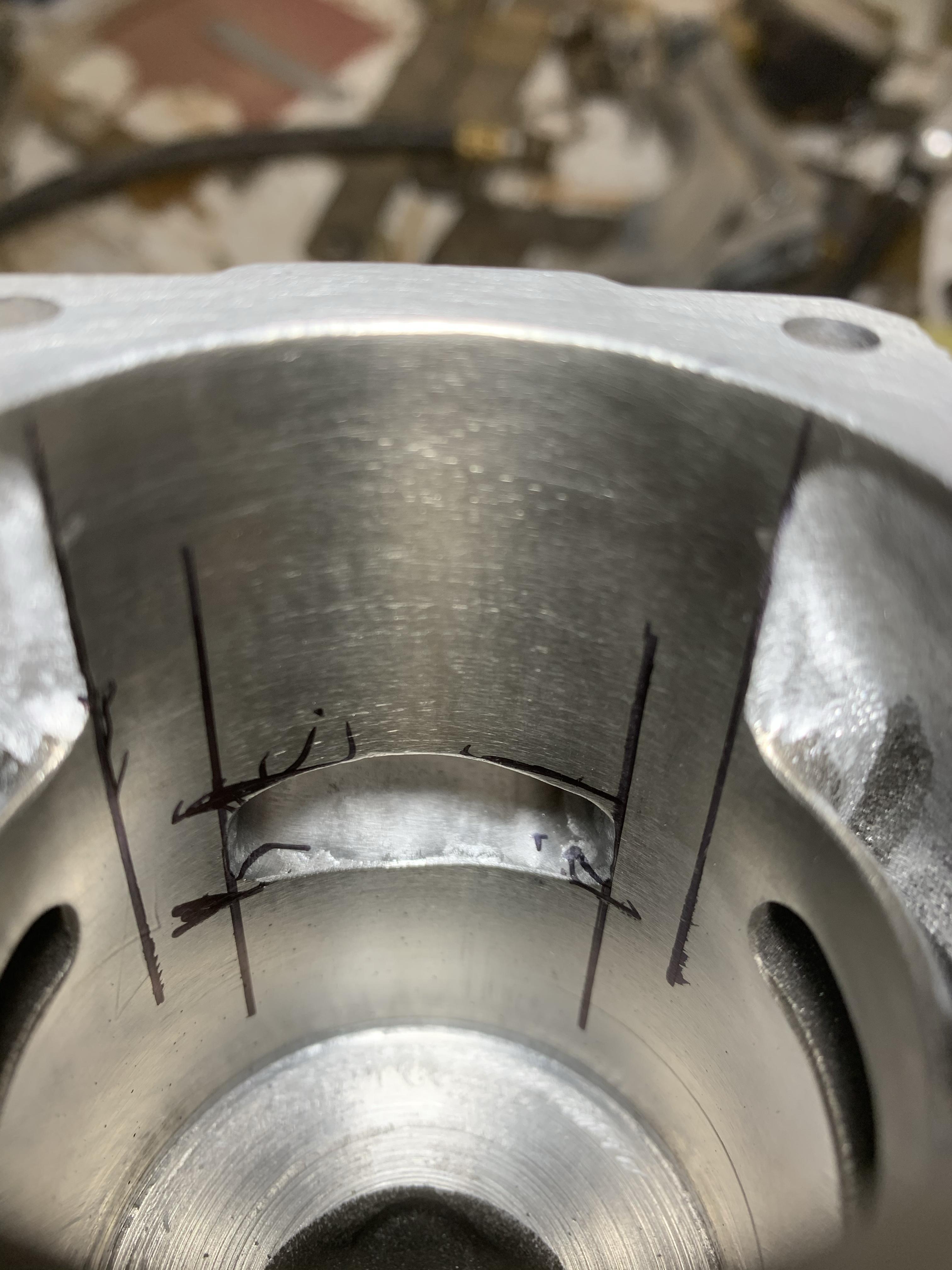

Widened the exhaust, intake and lower transfers.

Timing-

Ex 101

Tr 126

In 75

Now to cut the key, mod the muffler and reassemble.

Sent from my iPhone using Tapatalk Pro

Took .053 off the base

Set the squish with an OEM gasket

Widened the exhaust, intake and lower transfers.

Timing-

Ex 101

Tr 126

In 75

Now to cut the key, mod the muffler and reassemble.

Sent from my iPhone using Tapatalk Pro

Last edited: