[Brazing with HTS-2000 aluminium solder]

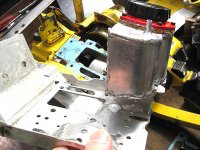

Lately I sometimes thinks of a necessity to have skill of jointing a small alu parts to other bigger part of a saw, e.g. a small fuel pipe to a alu fuel tank, etc. But smaller parts are mostly consist of thinner walls of alu plate which does not like dull-hand of a novice welder like myself, lol.

So instead I got this material for brazing alu things. They say HTS-2000 solder does not require any flux, so this sounds somewhat nice to me too. Here are some;

The surface of these rods looks kind of rough compared to e.g. some standard TIG filler rods, looks like the electric solder being chilled in a half-cut small pipe after it got melted and poured in there with free hands. So at the first glance you may not believe this can do a nice job, lol.

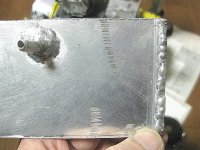

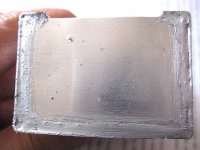

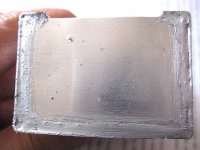

This is a small alu box for today's specimen, with 0.8mm thin walls. So this can be one of the examples that can not be done with a standard TIG machine. The walls are too thin to be welded with amperage larger than 20A, IMHO though.

Not so bad, the melted solder easily goes into the gaps and got flattened with a stainless brush.

Better use bigger air-propane torch.

Chy