Chainsaw Mick

Active OPE Member

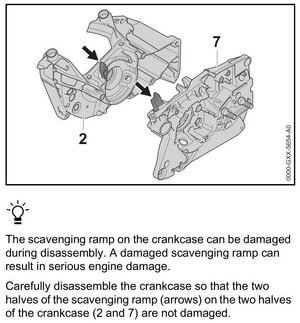

has anyone ever rebuilt 500i without the intake deflection part, type thing that is situated under the piston as it hits TDC?

Reason I’m asking is I have 500i and that part was badly damaged, as bottom end is scrap anyway I thought about grinding is down like normal Stihl crankcase and rebuilding to see what happens, how it runs.

Has this been done before and what would results be?

Reason I’m asking is I have 500i and that part was badly damaged, as bottom end is scrap anyway I thought about grinding is down like normal Stihl crankcase and rebuilding to see what happens, how it runs.

Has this been done before and what would results be?