As I wrap my head around this, I have discovered the current hardware methods being used to Advance timing on any electronic ignition saw will produce the same results as an M-Tronic.

Advancing the timing by means of a modified hardware key (lets say 5 degreese), will in all affect only do just that...

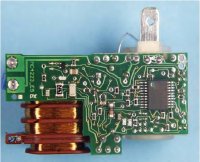

The internal chip / software only has one method of knowing TDC and that's thru the trigger sensor (on the Sparkplug side of the coil) and the flywheel.

As a result, if you take a stock M-Tronic, connect a timing light and take measurements at 1000, 4000, and 6000 RPM's, then do the same for a modified, 5 degree advanced saw, the timing light at those same speeds will be advanced by exactly 5 degrees.

There is no other sensor / method for the saws electronic ignition to know something has changed except for the trigger sensor.

Now if a software change could done to set a 5 degree advance, the saw would need to make 2 maybe 3 revolutions on Startup so as to Power Up the chip, read the trigger sensor, and make the preprogrammed adjustment.

On the other hand, some type of mechanical movement of the coil pack as the throttle is being used, could result in a faster responding acceleration because the coil would be physically advancing and retarding the timing....

Just throwing it out there.... Something that came into my head and needed to verbalize it....

LOL