afleetcommand

Pinnacle OPE Member

Does it work the same as Husqvarna "Autotunes"? The "Lean out tests" & feed back logic? Bet they do. Going to find out as a 441 is now a project saw. Acts a lot like the gen one autotunes....

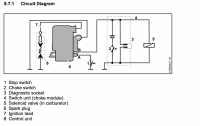

I suppose I could layout that process (Husqvarna's) , but not interested in offending by insulting anyones intelligence. Most here probably already know, and its for a true Husqvarna type to do that amyway. Actually simple and really clever. As Mr. Snelling pointed out a few pages back, saws are simple in their requirements as compared to other types of powered vehicles or equipment. Unless there is a quantum leap in controls technology for small two strokes, adding all kinds of hooks and controls might fall into the diminishing returns for the expense in my most humble opinion. Autotunes "smarts" really don't need to focus on anything except RPM or pulses from the ignition module, Throttle position, and how long the little solenoid controlled valve stays closed for both testing and then tuning. Really simple. Really effective. Oh yeah, temp & throttle position for startups along with controlling that little valve. Then once running goes into "tuning" logic. And amazingly they work!

So I'm going to watch and hopefully learn about those M-Tronic systems.

I suppose I could layout that process (Husqvarna's) , but not interested in offending by insulting anyones intelligence. Most here probably already know, and its for a true Husqvarna type to do that amyway. Actually simple and really clever. As Mr. Snelling pointed out a few pages back, saws are simple in their requirements as compared to other types of powered vehicles or equipment. Unless there is a quantum leap in controls technology for small two strokes, adding all kinds of hooks and controls might fall into the diminishing returns for the expense in my most humble opinion. Autotunes "smarts" really don't need to focus on anything except RPM or pulses from the ignition module, Throttle position, and how long the little solenoid controlled valve stays closed for both testing and then tuning. Really simple. Really effective. Oh yeah, temp & throttle position for startups along with controlling that little valve. Then once running goes into "tuning" logic. And amazingly they work!

So I'm going to watch and hopefully learn about those M-Tronic systems.

Last edited: