I got bored while waiting for new rings for the OEM piston so I ported a big bore cylinder here's the first run. 28 inch full comp square grind rakers next to non existent.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

046 big bore

- Thread starter StihlEchoingHusky

- Start date

Outdoors

Well-Known OPE Member

- Local time

- 6:45 AM

- User ID

- 8243

- Joined

- Dec 30, 2018

- Messages

- 72

- Reaction score

- 217

- Location

- Spruce Pine

Looks good, nice job! What cylinder did you go with?

It's just a hyway titanikel big bore and at that a free porting cylinder. Sure does rip though. It will be a OEM again here very soon right after I finish buttoning up my 365. Yes My 365 looks off color wise damn previous owner painted the engine cover and the clutch cover. It all says made in Sweden though haha (farmertec pro trigger idk why but I like them)Looks good, nice job! What cylinder did you go with?

Outdoors

Well-Known OPE Member

- Local time

- 6:45 AM

- User ID

- 8243

- Joined

- Dec 30, 2018

- Messages

- 72

- Reaction score

- 217

- Location

- Spruce Pine

Is the titanikel hard to work with when porting?

Diamond burrs slow speeds. Foredom Vstones work aswell and foredom blue ceramics work really good for port chamfering. I honestly prefer the ceramics for chamfering vs diamond it comes out cleaner on any of the plating. Atlease that's what I've foundIs the titanikel hard to work with when porting?

Jake Dykstra

Super OPE Member

- Local time

- 3:45 AM

- User ID

- 7947

- Joined

- Nov 25, 2018

- Messages

- 256

- Reaction score

- 730

- Location

- NW Washington

That sounds good!

I went with a 66 piston in mine. Longer skirt allowed for chamber/base cut.

Runs pretty good but damn that thing drinks fuel like a nitro car.

Which is weird cuz my bb 390 sips fuel like a prius and makes more power. Guessing the port work i did is more efficient on the 390 is all i can figure.

I've had great luck with the titan nickel cylinders. That said I take way to long to port a cylinder.

I went with a 66 piston in mine. Longer skirt allowed for chamber/base cut.

Runs pretty good but damn that thing drinks fuel like a nitro car.

Which is weird cuz my bb 390 sips fuel like a prius and makes more power. Guessing the port work i did is more efficient on the 390 is all i can figure.

I've had great luck with the titan nickel cylinders. That said I take way to long to port a cylinder.

I've had one titanikel failure. Burr had broken teeth. Other than that I've had good luckThat sounds good!

I went with a 66 piston in mine. Longer skirt allowed for chamber/base cut.

Runs pretty good but damn that thing drinks fuel like a nitro car.

Which is weird cuz my bb 390 sips fuel like a prius and makes more power. Guessing the port work i did is more efficient on the 390 is all i can figure.

I've had great luck with the titan nickel cylinders. That said I take way to long to port a cylinder.

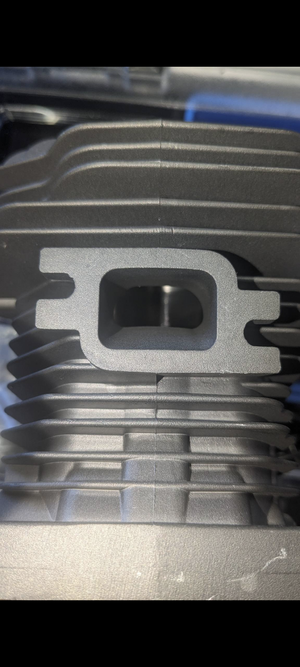

I haven't broken it in yet to where I feel comfortable enough to put it in wood but here's a ms250 titanikel pre portworkThat sounds good!

I went with a 66 piston in mine. Longer skirt allowed for chamber/base cut.

Runs pretty good but damn that thing drinks fuel like a nitro car.

Which is weird cuz my bb 390 sips fuel like a prius and makes more power. Guessing the port work i did is more efficient on the 390 is all i can figure.

I've had great luck with the titan nickel cylinders. That said I take way to long to port a cylinder.

I know clarity is garbage. I didn't realize my lens was so filthy. The rain stopped presenting me an opportunity to record a video. I was in a hurry before it started back uphere's the OEM cylinder with a meteor piston.

Jake Dykstra

Super OPE Member

- Local time

- 3:45 AM

- User ID

- 7947

- Joined

- Nov 25, 2018

- Messages

- 256

- Reaction score

- 730

- Location

- NW Washington

I agree with learning on the cheap ones. Sometimes the port timing is a bit different but can be ground to mimic the oem ones. I figure if am makes good cranking compression and ports can be ground similar then they can work just as well and make excellent training or race cylinders.

Yep sharp burr is the key to success

Yep sharp burr is the key to success

Absolutely! Ive learned to go slowly at first. Now I won't touch carbide to any sort of plating. Doesn't matter if it's OEM nikasil,chrome aftermarket nikasil or titanikel. I grind plating away with diamond burrs and foredom v stones. Once the plating is gone I will finish up the stock removal with carbide. I think the biggest problem people have with titanikel plating is they go at it with carbide burrs. Single cut is like taking a high speed pry bar to it and double cut is like picking it off with a flat head screw driver. Diamond burrs at slow speeds is what it takes. Sure it takes longer to port the way I do it but I haven't had any plating flake off going this route.I agree with learning on the cheap ones. Sometimes the port timing is a bit different but can be ground to mimic the oem ones. I figure if am makes good cranking compression and ports can be ground similar then they can work just as well and make excellent training or race cylinders.

Yep sharp burr is the key to success

Similar threads

- Replies

- 7

- Views

- 709

- Replies

- 3

- Views

- 284