I finished crunching the #s on my saws last night, but was too tired to post afterwards. As a reminder, under MustangMike's method, at least 7 continuous data points are averaged to compute Hp (sometimes I use as many as 12 data points). I'll go in order of saw size. Also, usually the best chart is what should be used, but maybe not always. Many of my air filters were so dirty I'm surprised my saws did so well.

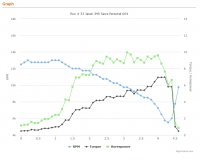

My little MMWS 362 C produced a best (chart 102) of 6.26 Hp, and a second best (chart 105) of 5.97 Hp. It is not as strong as the ported 262s, but to have a 60 cc saw with M-Tronic and spring AV produce about the same Hp as a stock MS460, I'll take it.

My modified (but not ported) MS440 produced the most consistent results: 6.76 Hp, 6.67 Hp, and 6.7 Hp. I was very impressed with those #s from a 70 cc saw w/o porting.

044#1 is also unported and has the exact same mods as MS440, and it hit the ball out of the park. I have owned this saw since new, and it has always been a strong performer, and just got better with the mods. The best two runs produced 7.56 (#116 after eliminating a high #) and 7.356 (run 115).

My MMWS 044#2 only had one good run that produced Hp of 7.538 Hp (run 107-1). Knowing how this saw compares to 044#1, I believe this run accurately reflects the power of this saw.

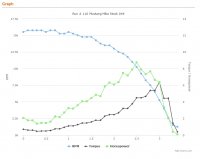

Now we come to my 3 ported 76.5 cc saws, and things get VERY INTERESTING.

MMWS MS460/046-D There were 5 runs for this saw (only 3 for all the rest) and they resulted in both the best and worst Hp #s, respectively for my ported 77 cc saws. The worst run (#130) produced 7.26 Hp, the best run produced 8.16 Hp (#129-3), narrowly edging out the saw Al did. The remaining 3 runs were very consistent, producing 7.66 Hp, 7.63 Hp and 7.57 Hp.

MS460/146-D Ported by Dr Al This saw provided the second most consistent results, and the highest average Hp with #s of 8.142, 7.98 and 7.787. This saw will put a smile on your face every time you run it.

Smittybilt 046 The best run from this saws produced 7.57 Hp, with the other two runs close behind.

Now here is were I have a little problem with the numbers. This reflects that the Smittybilt saw has about the same Hp as my two 044s. Let me assure you, all 3 of my ported 046-460s will easily out pull my 044s. Also note, that if you took the lowest 3 runs from the MMWS 460 they average about the same as the 3 Smittybilt runs, yet the MMWS also produced a run of over 8 Hp.

As my brother stated, 3 runs is a small sample. When you cut with the Smittybilt saw, it is noticeably stronger than the 044s. With more testing I am confident this saw would produce a run at or near 8 Hp.

I thank everyone involved in this project for providing us with such great information. This was very enlightening and I really enjoyed it.