Stihlin Time

Well-Known OPE Member

This is a walnut that we just finished cutting down. Part of the tree was taking down last summer. Just wanted to share and see if anyone has any ideas where to start. New to chainsaw milling. Not even sure where to start. I'm thinking that it could be valuable to the right person if it is milled correctly. I'll post some pictures along with rough measurements and see if anyone has any good ideas. With all the different limbs and crotches I think it should have some pretty cool grain patterns.

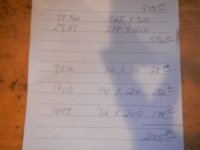

first piece is 40" at the butt end with the block x 55" at the other end where it spit at the widest point x 6 foot long

Next piece is 27" at the butt end, has a limbs half way through the middle of log and then goes back down and is 9 foot long.

The I just have 2 logs that are cut at 8'4" that are about 16" and another one about the same diameter and is longer but will probably cut down to make 8 foot boards out of and just a few smaller odds and ends.

Just another look at the two bigger chunks. There is still some other pieces that I don't have pictures for, but they are smaller and not as big of diameter

Hopefully pictures turned out. still trying to figure out how to get them on here with out leaving attachments and big enough to be able to see them. Looking for any and all advice on what to do with them.

first piece is 40" at the butt end with the block x 55" at the other end where it spit at the widest point x 6 foot long

Next piece is 27" at the butt end, has a limbs half way through the middle of log and then goes back down and is 9 foot long.

The I just have 2 logs that are cut at 8'4" that are about 16" and another one about the same diameter and is longer but will probably cut down to make 8 foot boards out of and just a few smaller odds and ends.

Just another look at the two bigger chunks. There is still some other pieces that I don't have pictures for, but they are smaller and not as big of diameter

Hopefully pictures turned out. still trying to figure out how to get them on here with out leaving attachments and big enough to be able to see them. Looking for any and all advice on what to do with them.