cease232

Pinnacle OPE Member

- Local time

- 9:26 PM

- User ID

- 1443

- Joined

- Jun 20, 2016

- Messages

- 524

- Reaction score

- 1,730

- Location

- Montana

I've seen this question asked more than a few times over the years and thought I would take a shot at it. I'm more of a woodworker than a machinist so I had to figure out how to do this with woodworking tools. I did use a wood lathe but don't think it's entirely necessary.

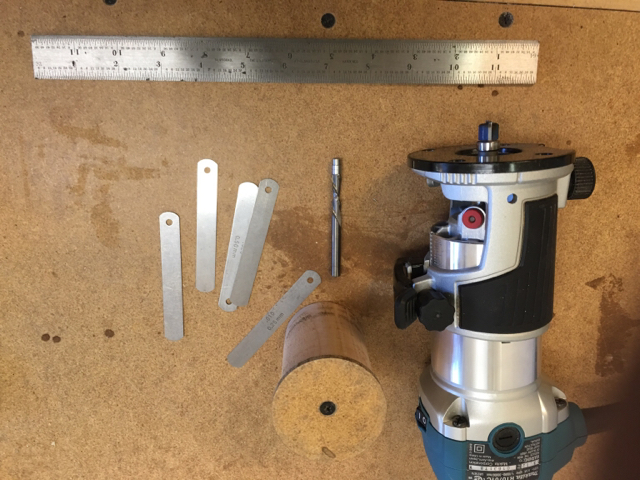

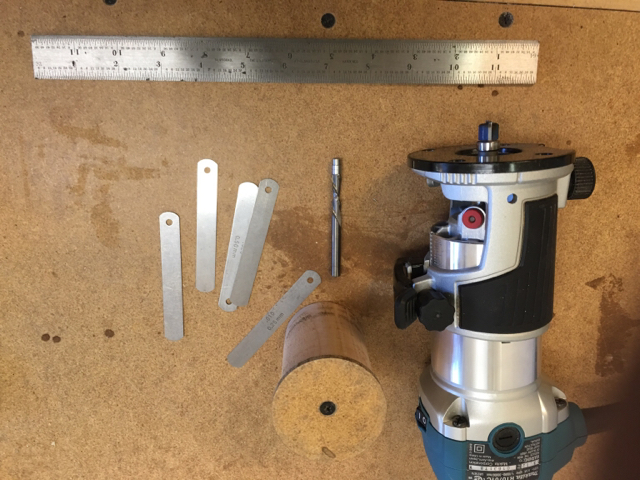

I used a router (variable speed Palm router), feeler gauges, a straightedge (to check my work), two router bits, and shop made jig/mandrel.

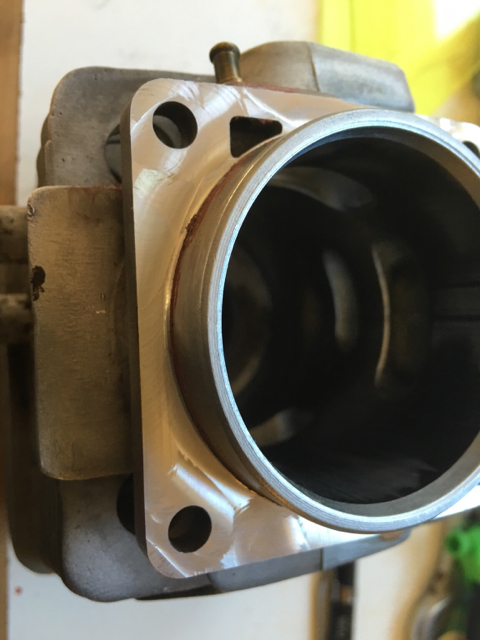

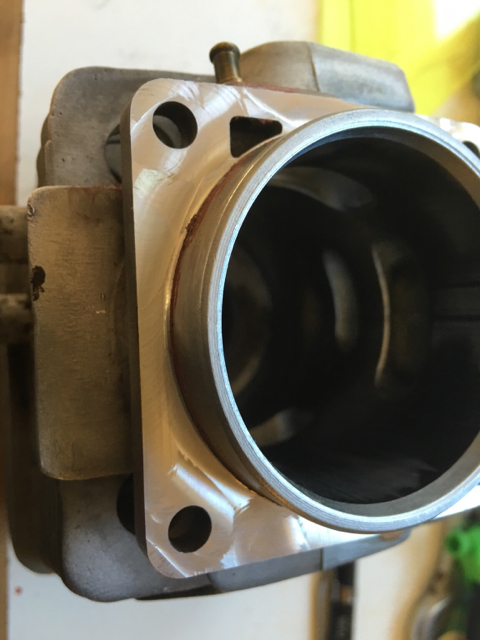

Donor jug. Squish was 0.065 with no gasket so I was shooting for taking off 0.045.

Shop made mandrel, turned on my wood lathe but I think square stock would work just as well.

First pass was made with this template bit to make the hardboard top the same diameter as the lip of the cylinder.

Then using feeler gauges I started taking off 0.0100 at a time, takes a steady hand and firm downward pressure with the router against the mandrel.

Results were excellent IMHO.

Squish after machining. Took 4 passes. One pass I took 0.015

Next time I plan on using an end mill. The bit I was using is of very low quality. Let me know what you think. It could probably be improved but I threw this together on a whim this afternoon.

Jeremiah

I used a router (variable speed Palm router), feeler gauges, a straightedge (to check my work), two router bits, and shop made jig/mandrel.

Donor jug. Squish was 0.065 with no gasket so I was shooting for taking off 0.045.

Shop made mandrel, turned on my wood lathe but I think square stock would work just as well.

First pass was made with this template bit to make the hardboard top the same diameter as the lip of the cylinder.

Then using feeler gauges I started taking off 0.0100 at a time, takes a steady hand and firm downward pressure with the router against the mandrel.

Results were excellent IMHO.

Squish after machining. Took 4 passes. One pass I took 0.015

Jeremiah