- Local time

- 4:25 AM

- User ID

- 522

- Joined

- Jan 12, 2016

- Messages

- 3,943

- Reaction score

- 26,001

- Location

- Iowa City

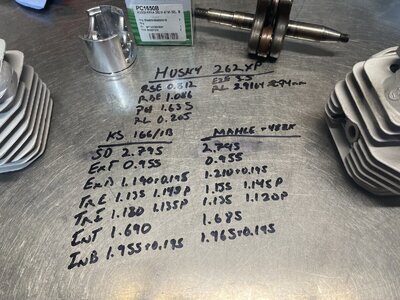

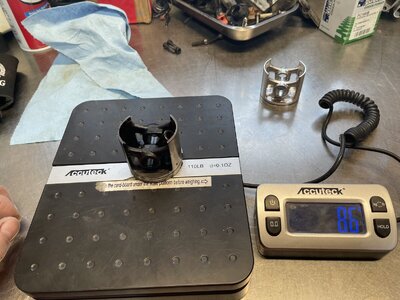

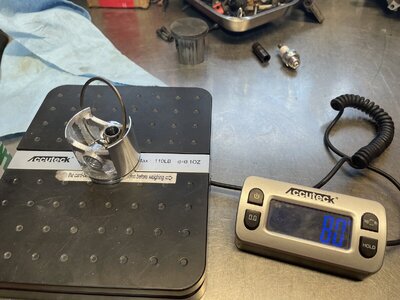

Since I received a 262 cylinder and carb in the fundraiser a little while back I decided to pull this 262 project out of the moth balls.

Sorry, no tear down pictures. There wasn't much to see but the pound of grease and sawdust it left on my bench.

So we'll start here with the clean case and new nachi open bearings.

Wipe the rust preventative off the bearings or they'll stick on you. Since this saw has a blind bearing pocket on the PTO side and a through hole on the flywheel side we'll start on the PTO side.

A little heat from a map gas torch gets us this far. Heat the case 1/2, slip the bearing in. Wait for it to heat soak and add a little more heat to the inner race to slip the crank in. Then hold the other bearing with channel locks while you heat it and then slip it onto the flywheel side of the crank. While this cools it's a good time to clean the case bolts up.

Sorry, no tear down pictures. There wasn't much to see but the pound of grease and sawdust it left on my bench.

So we'll start here with the clean case and new nachi open bearings.

Wipe the rust preventative off the bearings or they'll stick on you. Since this saw has a blind bearing pocket on the PTO side and a through hole on the flywheel side we'll start on the PTO side.

A little heat from a map gas torch gets us this far. Heat the case 1/2, slip the bearing in. Wait for it to heat soak and add a little more heat to the inner race to slip the crank in. Then hold the other bearing with channel locks while you heat it and then slip it onto the flywheel side of the crank. While this cools it's a good time to clean the case bolts up.