Khntr85

Pinnacle OPE Member

- Local time

- 11:18 PM

- User ID

- 1180

- Joined

- Apr 20, 2016

- Messages

- 1,088

- Reaction score

- 1,952

- Location

- Indiana

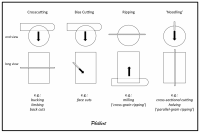

Thank you philbert as always.... I actually remember @Brush Ape told me the angles for ripping chain after I posted that!!!!You might want to pose this in the 'Milling' forum. They actually use them. Otherwise, I would just be quoting you stock angles from the catalogs.

Philbert

Last edited: