It is safe to say you found a fuel that does not work for your application, but you cannot equate that directly to it being an octane rating problem, there is allot more to a fuel than that once point, it's kind of like the old four stroke back pressure myth, bigger exhausts lost power and missing back pressure got the blame, when it was the reduced velocity or tuning rpm that caused most of the loss.

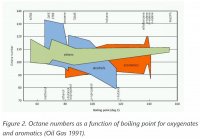

Below are different types of fuels, their possible octane ratings and boiling points, as you can see, it is choose your octane and take your pick of how to get there, many options exist.

View attachment 289862

As I mentioned, knock being caused by simply too fast of a primary rapid heat release is a discredited theory, one that academics of the 60s sparred over.

Having said that, the chemical reactions that underpin knock are still studied to this day, anti knock additives such as TEL (lead) do not act buy slowing primary combustion, they rather magically have little effect until the factors for knock exist, once conditions for knock start, when end gasses begin to break down to form highly reactive radicals, then the TEL joins to these free radicals, mopping them up/stabilizing them, knock problem solved, I assume (yes) they then burn at the correct time when the primary flame front reaches them.

Current methods for increasing octane are more just diluting the fuel with another higher octane substance, which could increase or decrease burn rate.

Below some more fuel vs burning velocity, unfortunately there are some discrepancies with other studies, but these are not from inside an operating internal combustion engine, the point being that there is not a strong correlation between octane rating and burning velocity, iso-octane (AKI 100) and toluene (AKI 114) one of the easiest to get high octane fuels are fairly close,

View attachment 289885

Seems likely.