Ironworker

Super OPE Member

- Local time

- 7:20 PM

- User ID

- 430

- Joined

- Jan 7, 2016

- Messages

- 261

- Reaction score

- 569

- Location

- Orange County NY

What is the difference in these apparently all fit on 357's or 359's also I've seen 196 and 190, learn me please.

The accelerator pump is responsible for providing the momentary additional fuel needed under heavy acceleration conditions. When the trigger or pedal is pressed, the throttle suddenly opens, immediately adding additional air for additional power. That additional air requires additional fuel, especially in the precise moments after the throttle is opened, this is the fuel the accelerator pump provides. When the throttle is rapidly opened, the accelerator pump will squirt a small amount of fuel into the throat of the carburetor so that the engine can continue running smoothly under increased load. Usually when the accelerator pump is having issues, it will display a few symptoms that can alert the operator that there may be a problem that should be inspected.

Rough acceleration

One of the most common symptoms that the accelerator pump is having a problem is rough or sluggish acceleration. The accelerator pump is supposed to provide additional fuel needed during acceleration. If there is any problem with the pump, then there will be a problem in the fuel mixture during acceleration. Usually, a faulty accelerator pump will result in a momentary lean condition, which can result in rough or sluggish acceleration, and even misfires.

Engine sputtering or stalling

Another symptom of a faulty accelerator pump is engine sputtering or stalling. The sputtering is caused by the lack of fuel that is supposed to be provided by the accelerator pump when throttle is rapidly pressed. In more serious cases of accelerator pump failure, rapidly pressing on the gas may cause the engine to stall, again due to the lean condition that can be created when the accelerator pump is not working.

A faulty accelerator pump will typically produce a noticeable effect on the engine performance when it fails or is having a problem. If you suspect that your accelerator pump may be having an issue, have the carburetor diagnosed by a professional technician.

I know this is an old thread, and there are posts all over asking these questions. But I just wanted to share some information, in case it is useful to anyone in the future.

1. The 357XP and 359 were introduced in 2001. Depending on the locale where they were sold, they either came with a Walbro HDA-174 or an EPA regulated Walbro HDA-175. The differences between these two carbs will become clear as an emerging pattern, as Walbro provides the 174 as a normal carb with a 16.66mm venturi, and the 175 as an EPA compliant carb. The major difference was the 175 had smaller jets, so to achieve faster acceleration it had a built in accelerator pump. Since the accelerator pump is such a crucial difference, it may be useful to understand what it is and does.

The HDA-175 also had adjustment needles with limiters and a different metering spring providing different pop-off pressure.

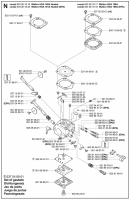

View attachment 143841

Around 2004 the HDA-174 and HDA-175 were discontinued by Walbro, forcing Husqvarna to select new carbs for their product.

View attachment 143842

2. In April 2003 Husqvarna updated their 357XP and 359 to use 4 new carbs! All four carbs still use a 16.66mm venturi. The particular carb choice is dependent on two qualifications: the first is if the saw came with handle heating (357XPG and 359G) or without handle heating (357XP and 359), and the second qualification is if the saw was sold in a locale requiring EPA regulation compliance, or not. Saws with handle heating received a Walbro HDA-190A, or a Walbro HDA-191A if they needed to meet EPA regulations. Saws without handle heating received a Walbro HDA-198A, or a Walbro HDA-199A if they needed to meet EPA regulations. Again, the major differences between the non-EPA and the EPA carbs are the restriction of jet size, adjustment needles with limiters and an accelerator pump.

The major difference between the heated handle carbs (190 and 191) and the non-heated handle carbs (198 and 199) was the inclusion of a plastic ring (537 04 53-01) at the top of the carb on non-heated handle carbs. This was Walbro's version of a compensating carburetor, similar to Stihl's Intellicarb idea. The principle was there was a passageway which allowed the backside of the metering diaphragm to have access to the pressure inside the intake track, after the air filter. The concept was that as the air filter gets clogged up, a more negative pressure develops and more fuel would be sucked through the carb without as much air, resulting in a rich condition. To compensate, the negative pressure was added to the top side of the metering diaphragm to counter-act the pressure difference. Scott Kunz (@Treemonkey) believes this to be a poor design, because the passage way is small. He tends to solve problems with HDA-199 carbs by making them like 191 carbs. The 191 carbs do not have a plastic ring at the top of the carb, because the ring thermally decoupled the top cover where the carb heater sat. Therefore, on heated handle (and carb) saws, the 190/191 carb was used, without a ring, and with a simple hole drilled in the top cover, and no compensation.

After 2005, EU regulations meant saws sold there received the EPA version carbs.

View attachment 143844

Walbro has never provided instructions or parts to service the accelerator pump. Whether due to fuel quality or simply a limited lifetime, the accelerator pump would often get gummed up and stick, causing running problems. The easy fix was to replace the whole carb, as most small-engine technicians were not going to go through the trouble to diagnose, remove, service, and replace an accelerator pump.

3. In October 2008 Husqvarna introduced a service bulletin to change the carb on the 357XP and 359 again, this time to the Zama C3-EL42, ostensibly for better idling stability.

Regarding the use of these carbs on 346XP saws.

Any of these Walbro carbs will be a direct swap into a 346XP, however, little gain would be seen on a stock saw, while only modest gain might be seen on a gasket delete/muffler mod. To take advantage of the larger gains possible with these carbs would require full port jobs to a cylinder. Of all the carb choices, I would suggest given the choice between two carbs that the non-EPA, non accelerator pump carbs would be preferable. That means an HDA-174, HDA-190, or HDA-198. These carbs are, however, more rare, since less saws were produced with them. There is nothing wrong with using an EPA carb from a 357XP/359, although they too are becoming harder to find. The only downside is that the additional complication of the accelerator pump may mean they have a shorter service life due to a possible failure of the accelerator pump. I am also not certain if the possibility for failure of the accelerator pump would outweigh its benefit for a ported saw. It may be that the accelerator pump version carb performs better? Only side-by-side testing would show that.

The EL-42 carb will also work for a 346XP upgrade, however, it may not deliver enough fuel to a ported saw. There is a modification that can be made to drill out the jet, which is detailed here, to increase fuel delivery.

The 199 has always been the hot rod carb for the 346’s I’ve been toldI know this is an old thread, and there are posts all over asking these questions. But I just wanted to share some information, in case it is useful to anyone in the future.

1. The 357XP and 359 were introduced in 2001. Depending on the locale where they were sold, they either came with a Walbro HDA-174 or an EPA regulated Walbro HDA-175. The differences between these two carbs will become clear as an emerging pattern, as Walbro provides the 174 as a normal carb with a 16.66mm venturi, and the 175 as an EPA compliant carb. The major difference was the 175 had smaller jets, so to achieve faster acceleration it had a built in accelerator pump. Since the accelerator pump is such a crucial difference, it may be useful to understand what it is and does.

The HDA-175 also had adjustment needles with limiters and a different metering spring providing different pop-off pressure.

View attachment 143841

Around 2004 the HDA-174 and HDA-175 were discontinued by Walbro, forcing Husqvarna to select new carbs for their product.

View attachment 143842

2. In April 2003 Husqvarna updated their 357XP and 359 to use 4 new carbs! All four carbs still use a 16.66mm venturi. The particular carb choice is dependent on two qualifications: the first is if the saw came with handle heating (357XPG and 359G) or without handle heating (357XP and 359), and the second qualification is if the saw was sold in a locale requiring EPA regulation compliance, or not. Saws with handle heating received a Walbro HDA-190A, or a Walbro HDA-191A if they needed to meet EPA regulations. Saws without handle heating received a Walbro HDA-198A, or a Walbro HDA-199A if they needed to meet EPA regulations. Again, the major differences between the non-EPA and the EPA carbs are the restriction of jet size, adjustment needles with limiters and an accelerator pump.

The major difference between the heated handle carbs (190 and 191) and the non-heated handle carbs (198 and 199) was the inclusion of a plastic ring (537 04 53-01) at the top of the carb on non-heated handle carbs. This was Walbro's version of a compensating carburetor, similar to Stihl's Intellicarb idea. The principle was there was a passageway which allowed the backside of the metering diaphragm to have access to the pressure inside the intake track, after the air filter. The concept was that as the air filter gets clogged up, a more negative pressure develops and more fuel would be sucked through the carb without as much air, resulting in a rich condition. To compensate, the negative pressure was added to the top side of the metering diaphragm to counter-act the pressure difference. Scott Kunz (@Treemonkey) believes this to be a poor design, because the passage way is small. He tends to solve problems with HDA-199 carbs by making them like 191 carbs. The 191 carbs do not have a plastic ring at the top of the carb, because the ring thermally decoupled the top cover where the carb heater sat. Therefore, on heated handle (and carb) saws, the 190/191 carb was used, without a ring, and with a simple hole drilled in the top cover, and no compensation.

After 2005, EU regulations meant saws sold there received the EPA version carbs.

View attachment 143844

Walbro has never provided instructions or parts to service the accelerator pump. Whether due to fuel quality or simply a limited lifetime, the accelerator pump would often get gummed up and stick, causing running problems. The easy fix was to replace the whole carb, as most small-engine technicians were not going to go through the trouble to diagnose, remove, service, and replace an accelerator pump.

3. In October 2008 Husqvarna introduced a service bulletin to change the carb on the 357XP and 359 again, this time to the Zama C3-EL42, ostensibly for better idling stability.

Regarding the use of these carbs on 346XP saws.

Any of these Walbro carbs will be a direct swap into a 346XP, however, little gain would be seen on a stock saw, while only modest gain might be seen on a gasket delete/muffler mod. To take advantage of the larger gains possible with these carbs would require full port jobs to a cylinder. Of all the carb choices, I would suggest given the choice between two carbs that the non-EPA, non accelerator pump carbs would be preferable. That means an HDA-174, HDA-190, or HDA-198. These carbs are, however, more rare, since less saws were produced with them. There is nothing wrong with using an EPA carb from a 357XP/359, although they too are becoming harder to find. The only downside is that the additional complication of the accelerator pump may mean they have a shorter service life due to a possible failure of the accelerator pump. I am also not certain if the possibility for failure of the accelerator pump would outweigh its benefit for a ported saw. It may be that the accelerator pump version carb performs better? Only side-by-side testing would show that.

The EL-42 carb will also work for a 346XP upgrade, however, it may not deliver enough fuel to a ported saw. There is a modification that can be made to drill out the jet, which is detailed here, to increase fuel delivery.

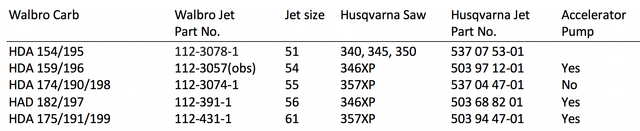

surprises with jet size: (I bought them in for some time ago since I was currious )

HDA 154 (350), # 537 07 53 01, jet size 51

HDA 159 (346), # 503 97 12 01, jet size 54

HDA 198 (357), # 537 04 47 01, jet size 55

HDA 182 (346), # 503 68 82 01, jet size 56

HDA 199 (357), # 503 94 47 01, jet size 61

its my understanding that they used the limiters cap to fullfill the EPA restrictions, most of them came adjusted a tad to the lean side.Hi Tor, thanks for this info. It's perplexing to me to see that the HDA-198 and HDA-199 carbs have jet sizes the opposite of what I would expect, and there is quite a difference between the two 357XP carb jet sizes! One has a #55 and the other has a #61 and an accelerator pump, but is listed as an EPA carb! Are you sure about these numbers? I had thought that the accelerator pump was necessary to provide the "oomph" that was lacking due to the smaller jet size which allowed the carb (saw) to meet EPA restrictions.

and 182 has an accelerator pump as well.Interestingly, you say the HDA 182 used on a 50cc saw actually has a larger jet size than the 198 used on a 60cc saw?

you can set the class of 346 walbro carbs up this way:The 346 went through a NUMBER of carbs! The 1999 346XP IPL had the HDA-154A and HDA-159A carbs superseded to the HDA-182 and HDA-159 EPA, respectively. Then in 2001 the HDA-182 was superceded to the Zama C3-EL17, while the HDA-159 EPA was superseded to the Zama C3-EL18 EPA. This changed in 2007 when the C3-EL17 was dropped and everything used the C3-EL18, until 2009 when it was superceded to the Zama C3EL32, and then superseded to the Zama C3EL51 in 20011. All the Zama carbs had a 15mm venturi, while the Walbro carbs had a 15.08mm venturi. According the the Walbro website, apparently the 346XP also had an HDA-187 carb at one point? I can't figure out when that was.

Zama C3EL32 was introduced in 2007 month 8 with 346 NEThis changed in 2007 when the C3-EL17 was dropped and everything used the C3-EL18, until 2009 when it was superceded to the Zama C3EL32, and then superseded to the Zama C3EL51 in 20011

walbro have had or has accelerator kit to several of their carburetors with the pump. I belive the items has # 160-xxx or 160-xxx-xWalbro has never provided instructions or parts to service the accelerator pump. Whether due to fuel quality or simply a limited lifetime, the accelerator pump would often get gummed up and stick, causing running problems. The easy fix was to replace the whole carb, as most small-engine technicians were not going to go through the trouble to diagnose, remove, service, and replace an accelerator pump.

its not that plain simple with the conclussion of HDA 190/191 vs HDA 198/199.. In April 2003 Husqvarna updated their 357XP and 359 to use 4 new carbs! All four carbs still use a 16.66mm venturi. The particular carb choice is dependent on two qualifications: the first is if the saw came with handle heating (357XPG and 359G) or without handle heating (357XP and 359), and the second qualification is if the saw was sold in a locale requiring EPA regulation compliance, or not. Saws with handle heating received a Walbro HDA-190A, or a Walbro HDA-191A if they needed to meet EPA regulations. Saws without handle heating received a Walbro HDA-198A, or a Walbro HDA-199A if they needed to meet EPA regulations.

that make sense for me Brian, in their first years they used the same generator on them all, later, most of my OE generators has the split for carb heaters even those I had never came with the carb heaters mounted.My OE 346xpg has the heaters on the carb.

No gas engine will accelerate off a lean carb. Because of this, the newest generation of lean running carbs give the intake a shot of fuel to provide for the rpm transition.

With a chainsaw or weed whacker with a regular carburetor, the low speed circuit has to be tuned richer so that the engine can accelerate to high speed. Therefore during normal idling, the engine runs rich. The best tuning for the low speed normally is to make the low speed as lean as possible where the engine will still be able to accelerate when you jerk the trigger.

With an accelerator pump carburetor, the idle needle can be tuned leaner for running at idle and the engine will still accelerate to high speed.

I experienced a problem with a new chainsaw and it took me a moment to figure out what was wrong because I didn't know in the beginning that the carburetor was different. I have a Husqvarna 357XP with the HDA-199 carburetor and this is an accelerator pump carburetor. When I first bought the saw, it would quit on me in the lower mid range speed area unless you wiggled the trigger a little every now and then. I then discovered that the carb had an accelerator pump and that for some reason the midrange was lean and the accelerator pump that would keep the chainsaw running was failing. I finally decided to make the low speed a little richer and the midrange running problem went away.

With this knowledge of the operation of my 357XP I feel that I would know if the accelerator pump would not work. But I also see the possibility that a bad accelerator pump carb could be tuned to run the chainsaw with a bad pump by making the mixtures richer but the overall running characteristics would not be as good as original new condition.

A long shot, but can you still get them?I can still get the HDA-198-1 new from one of my suppliers (when the local warehouse isn't out of stock for two months) and they are pretty reasonably priced.

A long shot, but can you still get them?