- Local time

- 3:42 AM

- User ID

- 5156

- Joined

- Jan 24, 2018

- Messages

- 9,648

- Reaction score

- 38,264

- Location

- Extreme Southeast CA

Excellent point

That's an interesting idea. In Stihls patent for Hexa, about half the document describes and shows a file like that. They had a small flat section in the bottom of the gullet that it rode on.So

There is another way…

Take a round file and grind the side flat to ride the floor of the tooth until you get the tooth profile you want. I’ve done it with 1/4” files for 3/8”. Sent some out to try haven’t heard back. Used it a few times myself, seemed to work.

So

There is another way…

Take a round file and grind the side flat to ride the floor of the tooth until you get the tooth profile you want. I’ve done it with 1/4” files for 3/8”. Sent some out to try haven’t heard back. Used it a few times myself, seemed to work.

That's an interesting idea. In Stihls patent for Hexa, about half the document describes and shows a file like that. They had a small flat section in the bottom of the gullet that it rode on.

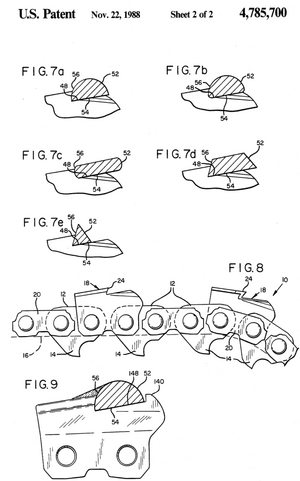

I had not seen the Oregon one before and it's an interesting idea. The small shelf that gets created when square filing acts as a basic form of guide once the same file has been used a few time. It's not perfect because you need to lower it down as it wears back but it is easier to align the file once that shape has been formed.In the 1980s, Oregon even took the trouble to patent a "cutting link for saw chain having guide surface for sharpening". "Just in case" they indicated several file shapes.

View attachment 437270

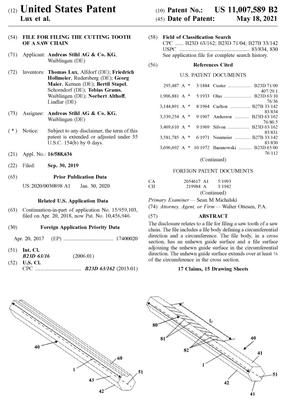

In addition to that patent for the cutter link (and files) (e.g. US 10,456,946) they obtained a separate patent for the file(s) (e.g. US 11,057,589).

View attachment 437271

Where do you get your info that only the top of the cutter cuts wood?Got to ask your self what makes a chain cut?

It's only the top of cutter that cuts wood.

Don't matter what's under the top one mm or so.

It's only there to hold the top up.

Hexa is only a sales gimmick in my opinion.

Grab a permanent marker and paint a couple of teeth then make a few cuts and inspect the chain. The harder the wood the less of the cutter that actually cuts.Where do you get your info that only the top of the cutter cuts wood?

Grab a permanent marker and paint a couple of teeth then make a few cuts and inspect the chain. The harder the wood the less of the cutter that actually cuts.

Now this changes depending on the style of cutter. Full chisel - only a very small part of the side plate will cut.

Semi chisel will use more over the side plate as it curves out further down the side plate and requires multiple passes to completely clear the kerf. Chipper uses most of the side plate with its big radius.

Safe assumption with FC - it will use the depth gauge height + 50% as the depth gauge penetrates the wood. In softwood it may dig deeper, hardwood less. A 30 thou raker will use 45 thou of the cutter.

Even shorter way of explaining it, about the thickness of the top plate is all that cuts.

Not sure I'm following you here. One of those posts is mine, the other is not.So, you do understand the difference between this post and your former post:

Yes? Because the above post is completely false. And your second post begins to hit the nail on the head.

By widening the "meat" under the top plate and where the top- and side-plates meet, you can increase dramatically the width of the chip/curl.

So yes, in fact the side-plate does quite a bit of cutting. The top-plate/working corner digs into the wood based on the depth gauge, while the side-plate begins its job.

Edit: I do agree with you, though, that hexa is most likely a gimmick. As has been said many times here before, it's main design-factor is for folks not great at sharpening to sharpen better/easier. Having personally not tried Hexa chain, and probably won't, I can't speak to this from a place of experience.

My bad, sir! I misread the user handleNot sure I'm following you here. One of those posts is mine, the other is not.

When you say widening the meat under the top plate, I'm assuming you are saying increasing the top plate cutting angle. If so, yes it increases cutting speed to a point. Around 50 degrees is the cut off point where they become to fragile to survive more then a few cuts. This is the most critical angle for chain to cut, it can be 0 degrees top plate / sharpening angle (IE ripping chain), it can have a vertical side plate (90 degree square, even 100 degree for ripping) and still cut as long as there is a good top plate cutting angle. Staying in the 50-60 degree range is ideal for most applications, 70 if it's very hard going.

Carrying that angle over to the side plate is where we run into problems. Continuing over and meeting in the corner (square) is a really efficient shape for chain. Carrying it all the way over into the side plate (round, Hexa, C83/85 etc) is a little more problematic. You take support away from the corner and increasing side plate angle in itself will normal slow chain once you cross below 75-80 degrees.

In a perfect world it would all be square but it's to hard for most people to use so we get different things. Hexa is a solution to controlling file height, it where the majority of people go wrong when sharpening