AVB

Super OPE Member

- Local time

- 5:48 PM

- User ID

- 1240

- Joined

- May 4, 2016

- Messages

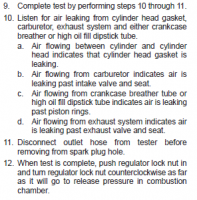

- 722

- Reaction score

- 789

- Location

- Elora, TN

Difference 2 cycle and 4 cycle is that with 2 cycles your looking for air leakage in the crankcase seals IE gaskets, mating surfaces, seals and intake boot or carburetor adapter and require block off plates for both the intake and exhaust ports. With 4 cycles your looking for leaking valves, head gaskets, cylinder and ring wear. You DON'T use the following tester on 2 cycles. Also on 2 cycle a vacuum crankcase test should be preformed.To be clear, explain the procedure of testing for leaks on a 4 cycle, what it entails, what you are looking at and why. Also explain how/why it is different from a crankcase leakdown test on a 2 cycle engine.

Also tell these guys of the dangers that they may encounter, they don't want to lose any fingers.......

As for dangers with the tester use is the use of too much pressure which on 2 cycles you don't use the following tester as it will blow a seal at minimum or worse. With besides the use too pressure is the rotational hazard especially if a blade is involved. Flywheels can cause serious injuries too if they move and your fingers or loose clothing is caught by them.

The following is from the Briggs and Stratton Service Manual on leak down testing. Although it says lock at TDC compression due the way ACRs are timed it should be done with the piston down 1/4" pass TDC. Also as mention if the OHV engine is involved you want to remove the valve cover as leaking head gasket between the cylinder and push rod galley will sound like bad rings otherwise if just listening at dip stick tube or breather tube. A good example is the Briggs 210000, 280000, 310000, and 330000 head gasket that are bad about blowing between the cylinder and push rod galley.