Cerberus

Cerberus the aardvark, not the hell-hound!!

- Local time

- 1:02 PM

- User ID

- 11523

- Joined

- Jan 20, 2020

- Messages

- 292

- Reaction score

- 120

- Location

- Florida (tampa area)

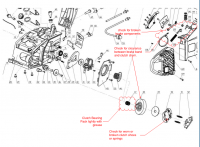

My clutch began weailing, initially thought it was , my bar (had just done heavy bar&chain clean&overhaul) but proved to be the clutch,I didn't remove it (ie jamming piston, and CW/counter-threaded removal of clutch&clutch's "exterior shell" which is both sprocket and clutch-band on this saw, like most climb saws!)but I *had been* greasing the tip of the drive-shaft with one of those smart Oregon grease-guns, feared it was the case//shaft interfacing, that maybe while cleaning w/ carb-cleaner I accidentally flushed-out heavy-grease andleft it dry at a main bearing or something, but this is certainly related to clutch-positioning IE if I tap the throttle it relieves it for a second (til idling again), if I put the chain brake on it makes it squeal way worse...

Had sprayed wd40 in-between clutch&clutch-band and it did shut it up entirely but I'd only used it another ~10min, when I went to use it today it was squealing again so I turned it off/used another saw as I don't want to destroy anything :/

Thanks for any advice, unit is 1yr old and has been kept-out of rain for almost-all of its use, I do clean regularly &aggressively with carb-cleaner spray (it's my "car wash" after usage!) but have kept it lubed and haven't beaten the hell out of it ie I don't stall-out the engine by forcing the bar too-often am pretty good about that!

Am afraid to even use the unit til I resolve this, squeling means some metal needs lube, but I know it shouldn't be the clutch/clutch-band interfacing! It's only 1yr, and I treat it well, but I did put a 12" on this 25cc, $135 ebay saw (scheppach csp2540, will be writing an A+ review soon *even if* the clutch is dead because I've put a TON of hours on this thing), while it isn't a fancy saw by any means though it has been impressive through&through (even after *just* getting a 355t - which is a frickin' dream, a marvel of engineering lol - I've still been taking the lil guy up for some stuff, down-graded his bar back down to the 10" (solid Oregon) bar it'd came with and'll be running VXL chain on it (has been impressive just using fresh/sharp safety chain though! )

)

Thanks for any advice! I can certainly rule-out dirt/debris, I didn't just spray w/ carb-cleaner I inspected real closely and there's nothing stuck/jammed anywhere! I know it needs lube somewhere just don't know where

Had sprayed wd40 in-between clutch&clutch-band and it did shut it up entirely but I'd only used it another ~10min, when I went to use it today it was squealing again so I turned it off/used another saw as I don't want to destroy anything :/

Thanks for any advice, unit is 1yr old and has been kept-out of rain for almost-all of its use, I do clean regularly &aggressively with carb-cleaner spray (it's my "car wash" after usage!) but have kept it lubed and haven't beaten the hell out of it ie I don't stall-out the engine by forcing the bar too-often am pretty good about that!

Am afraid to even use the unit til I resolve this, squeling means some metal needs lube, but I know it shouldn't be the clutch/clutch-band interfacing! It's only 1yr, and I treat it well, but I did put a 12" on this 25cc, $135 ebay saw (scheppach csp2540, will be writing an A+ review soon *even if* the clutch is dead because I've put a TON of hours on this thing), while it isn't a fancy saw by any means though it has been impressive through&through (even after *just* getting a 355t - which is a frickin' dream, a marvel of engineering lol - I've still been taking the lil guy up for some stuff, down-graded his bar back down to the 10" (solid Oregon) bar it'd came with and'll be running VXL chain on it (has been impressive just using fresh/sharp safety chain though!

Thanks for any advice! I can certainly rule-out dirt/debris, I didn't just spray w/ carb-cleaner I inspected real closely and there's nothing stuck/jammed anywhere! I know it needs lube somewhere just don't know where