KellyJackson

Need Husky 65L Parts/Saw

- Local time

- 4:26 PM

- User ID

- 22375

- Joined

- Jan 22, 2022

- Messages

- 8

- Reaction score

- 8

- Location

- Abbotsford ..

I know that the Pro's don't in a Lot of Cases, think that Painting or Powder Coating an a Couple Older Chainsaw is Sensible as I have Been Told by Some "Pros" that doing this is for People who are Glory or Shelf Chainsaw Inthuest's, That's Fine, Everyone is entitled to Think & Believe what they Will however it Depends what your Reasoning for Doing it is, Be it Personal, For Remembrance of Someone or Something in Particular, Doesn't really Matter.

For my Reasons, Being that I was Given a couple of Saws by a Friend whom I Hunted & Fished with, Cut so Many Cords of Wood with I could Never Count over the Years, Who I Learned so Much about Stewardship of Nature, Respect of Nature, and how Fickle Life can Be, I decided to Completely Rebuild a couple of Saws one being a 1991 Husky Model 55 c/w: 46mm Open Port Cylinder Assembly as well as an Older L65 Tomos

It amazed me the Comments from Some of the So Called "Pro's" or "Aficionado's" who have said Nothing other than " Why Waste your Time & Money" or "That OK if you Want your Saws to Fill a Shelf in Your Shop" Fact is I have my Reasons & Whatever they May be, In This case Out of Respect for a Good Friend Who Loved the Outdoors as Much or More than I do, I am Asking something Simple.

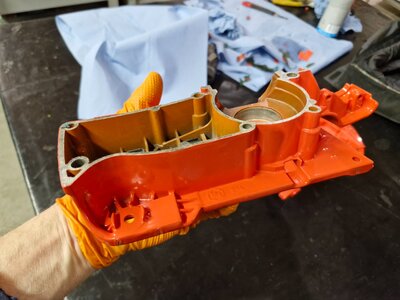

Can someone Advise me How to Prep a Magnesium or Aluminum Alloy Crankcase Saw such as an Older 1991 Year (Grey or Black Top) Model Husqvarna 55 Model or an even Older L65 Tomos (Yugoslavian Manufactured) Saw? Just Need to know if I Have to Sand Blast or Media Blast the Alloy Body to Remove All the Old Paint & Crud or Can I Boil away Most of the Dirt & Oil and Sand off the Old Paint? Should I Clean with Mineral Spirits afterwards before Painting or Powder Coating? I Know Painting isn't an Ideal Route to Take but its a Matter of Financial Sensibility.

As I said, Being an Avid Outdoorsman for so many Years' Just a Little over a Year & a Half Ago, After the " Covid 19 Pandemic" I was afflicted with a Knee Infection that eventually Resulted in an Amputation of my Leg Above the Knee which as I can only Simply Say " Put one Big Damper on My Outdoors Logging & Fishing Abilities to Say the Least. Not being a Pessimist,, I Decided that if I Couldn't do what I Enjoyed So Much, I would Take up a Hobby which has become Not Only Restoring Older Specific Chainsaws bu also Try and Help Wayward Street Kids or Under Privileged Kids to Learn Small Engine Repair, Primarily Chainsaws so that they May also Hopefully Learn something Useful as well as Get the Urge to Frequent the Outdoors other than the Streets.

In the Last 3-4 Years, Prices for Replacement Parts for Saws has become Insane Not to mention what "Flee Bay" wants for Shipping of these Parts and Even Worse, is the Vast Variety of Crap Parts and I Mean " Plain & Simple Garbage Parts" being Flogged on Multiple Sites & we all Know Who They are. Not Looking for Sympathy, Handouts, Nothing of the Sort, Just some Useful Help and Advice

For my Reasons, Being that I was Given a couple of Saws by a Friend whom I Hunted & Fished with, Cut so Many Cords of Wood with I could Never Count over the Years, Who I Learned so Much about Stewardship of Nature, Respect of Nature, and how Fickle Life can Be, I decided to Completely Rebuild a couple of Saws one being a 1991 Husky Model 55 c/w: 46mm Open Port Cylinder Assembly as well as an Older L65 Tomos

It amazed me the Comments from Some of the So Called "Pro's" or "Aficionado's" who have said Nothing other than " Why Waste your Time & Money" or "That OK if you Want your Saws to Fill a Shelf in Your Shop" Fact is I have my Reasons & Whatever they May be, In This case Out of Respect for a Good Friend Who Loved the Outdoors as Much or More than I do, I am Asking something Simple.

Can someone Advise me How to Prep a Magnesium or Aluminum Alloy Crankcase Saw such as an Older 1991 Year (Grey or Black Top) Model Husqvarna 55 Model or an even Older L65 Tomos (Yugoslavian Manufactured) Saw? Just Need to know if I Have to Sand Blast or Media Blast the Alloy Body to Remove All the Old Paint & Crud or Can I Boil away Most of the Dirt & Oil and Sand off the Old Paint? Should I Clean with Mineral Spirits afterwards before Painting or Powder Coating? I Know Painting isn't an Ideal Route to Take but its a Matter of Financial Sensibility.

As I said, Being an Avid Outdoorsman for so many Years' Just a Little over a Year & a Half Ago, After the " Covid 19 Pandemic" I was afflicted with a Knee Infection that eventually Resulted in an Amputation of my Leg Above the Knee which as I can only Simply Say " Put one Big Damper on My Outdoors Logging & Fishing Abilities to Say the Least. Not being a Pessimist,, I Decided that if I Couldn't do what I Enjoyed So Much, I would Take up a Hobby which has become Not Only Restoring Older Specific Chainsaws bu also Try and Help Wayward Street Kids or Under Privileged Kids to Learn Small Engine Repair, Primarily Chainsaws so that they May also Hopefully Learn something Useful as well as Get the Urge to Frequent the Outdoors other than the Streets.

In the Last 3-4 Years, Prices for Replacement Parts for Saws has become Insane Not to mention what "Flee Bay" wants for Shipping of these Parts and Even Worse, is the Vast Variety of Crap Parts and I Mean " Plain & Simple Garbage Parts" being Flogged on Multiple Sites & we all Know Who They are. Not Looking for Sympathy, Handouts, Nothing of the Sort, Just some Useful Help and Advice