Buckle up for some math and stuff... and since there is so much info, it is in a somewhat random order...

My first thought is the "tech" you spoke to is reading from some cookie-cutter flow chart...

I am going to assume your 4" cylinder has a 1.5" rod, as that is pretty typical of a cylinder that size.

A whining pump is almost always cavitation. This can be caused by a restriction on the inlet (plugged filter/screen?), too high/low viscosity of fluid, suction leak, or a reservoir running dry. It can also be a sign of a failing pump.

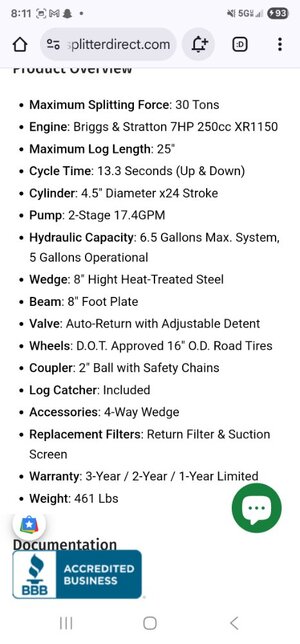

In your specfic case, I doubt the reservoir is running dry, as the system is a loop; everything not in the cylinder is being returned to the reservoir. A 4x24" cylinder will hold 1.3 gallons fully extended, and 1.1 gallons when fully retracted. When you extend the cylinder, the 1.1 gallons on the "rod" side of the cylinder is sent back to the reservoir, and the 1.3 gallons is pumped into the cylinder, leaving your 3gal reservoir with 2.8 gallons still.

If you go from your 16gpm 2 stage, to a 5-6gpm single stage, your splitting speed will definitely suffer.

Unloaded, your 16gpm pump is going to take ~5 seconds to extend, ~4 seconds to retract. If you drop to a 5gpm single stage, you will have 16 seconds to extend, 13 seconds to retract. You don't want that. There are ways to work the valving to get around this, but proper pump sizing is much easier.

Looking at the specs from your Rugged Made pump, the crossover is 600psi, once the pump sees 600psi, you are no longer 16gpm, but only 4gpm.

600psi in a 4" cylinder is just shy of 4 tons of force. If the wood you are splitting requires more than that, the 2nd stage of your pump will disengage, allowing the 1st stage to produce up to 3kpsi (caution, many cylinders are only rated for 2500). 3k psi in a 4" cylinder is nearly 19 tons of force. What this looks like in action is the ram moves "fast" until the force required to split the wood exceeds 4 tons, it will then "downshift" until the wood cracks, and then speed up again to complete the cycle. On a single stage pump, you will only move at the slow speed...

Hydraulics really only build heat when they are building pressure. When you are running both stages of your pump (16gpm) you are not really making any pressure (600psi max) and thus, not making any significant heat. An unloaded cylinder is going to be significantly less than 600psi. The only time you are really building any significant heat, is when your pump "downshifts." If the pump is whining immediately upon startup, and without load, it isn't a heat issue. If it runs for a bit amd then starts making noise, you may have a heat issue. I don't think you do, your reservoir isn't that small.

On the industrial side of things, we try to keep hydraulic reservoirs 3-5x the size of the pump, this is because this kind of equipment it is nearly always loaded, and we need that capacity to help control temps. A woodsplitter is not. A woodsplitter is typically only truly loaded less than 25% of the time, and thus can use much less capacity. On a residential splitter, 1:1 ratio on the high-pressure side of the pump is typically more than enough. For your pump, that means 4 gallon reservoir. Nearly all residential splitters have a reservoir of under 5 gallons, and a 16gpm pump isn't uncommon.

All that said, what would *I* do?

Assuming you cannot return this pump, and the goal is to make it work, I would start by going through the suction and return side very carefully. Eliminate any restrictions (cast 90° fittings are terrible), make sure your screens and filters are clean. Make sure you are using the viscosity of fluid and filtration recommended by the pump manufacturer. Make sure your tank breather is clear; a restriction in the breather can cause a vacuum to build in the tank, and cavitate the pump. If your pump feed and return are close to each other, the return flow may be causing air bubbles, which get sucked into the pump and sound like cavitation. In this case, baffles can help. If you have done all this, and the pump is still whining when cold, you probably have a defective pump.

If temps are legitimately an issue (140-150°F is fine, 160 wouldn't worry me much, 180 I'd raise an eyebrow), you can increase system capacity through use of larger hoses, and even an auxiliary cooler.

If I had an option of a different pump, I would choose one that allows you to adjust the crossover point, and allows you to actually use that 9hp engine; 600psi@16gpm only needs about 6hp, before it downshifts and goes to 4gpm@3000psi, which only requires 7hp. The pump you have would be a great match for a Harbor Freight 224cc, just set the relief valve at 2500psi (which is likely the cylinder max anyway).

Some 2 stage pumps allow up to 900psi on the 2nd stage, which conveniently 900psi@16gpm requires about 8.5hp. Keeping the 2nd stage active as long as you're able to keeps your splitter ram moving at the fast speed as long as possible. 900psi on a 4" ram is 5.5 tons, vs 3.75T you have before downshifting now with 600psi.

Due to your 3 gallon reservoir, I would want to limit your high pressure stage to around 3gpm, which also will limit the overall pump size. Most pumps with a 3gpm high pressure side are going to max out around 13gpm. There are some exceptions though; Wuxi Bucher makes a 14gpm pump that is on 1.4gpm on the high pressure side...

My choice of pump with a 9hp engine and 3gal reservoir would be a 13-16gpm two-stage, with 3-3.5GPM on the high-pressure side. I would want one that allows me to adjust the crossover point, and turn it up to 900psi, or until the engine stalls before downshifting, then back it off 50-100psi (whichever comes first). Set your relief valve to match the lowest rated component in the system, and run it.

Sorry for the novel... hydraulics are fun.