Nutball

Here For The Long Haul!

- Local time

- 5:35 PM

- User ID

- 7732

- Joined

- Oct 31, 2018

- Messages

- 4,284

- Reaction score

- 11,848

- Location

- Mt. Juliet, TN

I actually got to thinking last night about how wide I make transfer ports sometimes. I was going to check some of the cylinder kits I've practiced on today.So far so good. Put a half hour runtime on it last night. Ring pin is centered over the intake port. I saw it on the internet so it's gotta work right? LOL

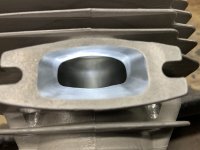

My concern with your cylinder was if the upper transfer is flat across the top and wide enough, it could catch a ring.

How wide does a flat port edge have to be to catch a ring? It would be nice to have a rule of thumb for the limit of width and minimum radius to avoid catching a ring.

Most rings have rounded edges which will wear off until it sharpens them razor sharp (even near 90 degrees). Then maybe that could cut away at a chamfer until it slams to a stop.