- Local time

- 4:02 PM

- User ID

- 25442

- Joined

- Nov 16, 2022

- Messages

- 279

- Reaction score

- 1,035

- Location

- Long Beach, IN

I'm about to embark on milling some logs I've gathered. Power will be a new ported G660 with Grandberg mill/chains on a 36" bar.

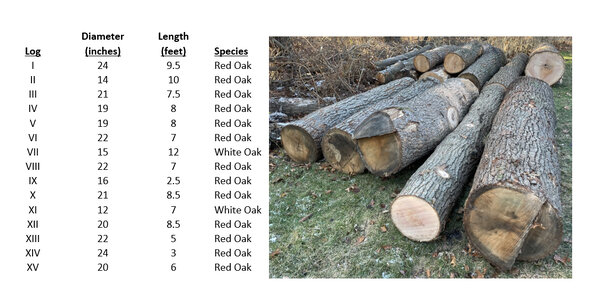

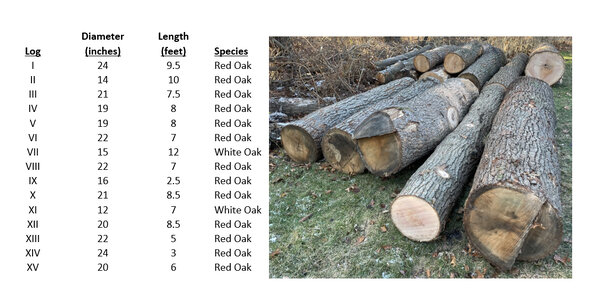

Here's what I have to work with:

Looking for recommendations on how to make the best use of this resource. I plan to do a few 2" slabs for some tables, and would also like to have this pile yield a significant amount of structural beams, say 4x6 or 6x6. I have a covered space ~ 20 yards away to sticker and dry.

Here's what I have to work with:

Looking for recommendations on how to make the best use of this resource. I plan to do a few 2" slabs for some tables, and would also like to have this pile yield a significant amount of structural beams, say 4x6 or 6x6. I have a covered space ~ 20 yards away to sticker and dry.