You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Milling chain

- Thread starter 661joe

- Start date

Douglas Ostrander

Here For The Long Haul!

- Local time

- 3:36 PM

- User ID

- 8

- Joined

- Dec 4, 2015

- Messages

- 867

- Reaction score

- 5,510

- Location

- Waukee Iowa next to I80

I can get way with low rakers with 35 hp motor.

Sent from my SM-N950U using Tapatalk

Sent from my SM-N950U using Tapatalk

Marshy

WFO Cutting

- Local time

- 4:36 PM

- User ID

- 417

- Joined

- Jan 5, 2016

- Messages

- 3,800

- Reaction score

- 13,111

- Location

- Mexico NY

http://treefalling.comAny recommended file guides? I'm pretty handy with a round file, but square is take some practice for me.

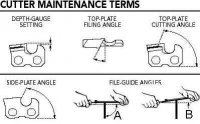

Yes, follow that link. You dont need to get as anal as this guy but it gives you the info you need and more. I have used a triangular file in the granberg jig with out modifying it in any way. The drawback was trying to get the side plate at the right angle. Once I round the nose of the thumb screws I will be able to roll the file and get the proper side plate angle.

Speaking of hitting metal in trees... I had a PM conversation with this guy and it proved to be interesting. He was in fact looking to be compensated for the trees that knowingly had metal in them.

Marshy

WFO Cutting

- Local time

- 4:36 PM

- User ID

- 417

- Joined

- Jan 5, 2016

- Messages

- 3,800

- Reaction score

- 13,111

- Location

- Mexico NY

You need to file deeper into the gullet of the tooth. The hook angle is very shallow even for cross cutting. I like my milling chain too have more hook than cross cut chain. Just my opinion of course.This is 27RX milling chain with raker taken down to 0.058. Stock chain is measuring 0.025. Should be 0.030. Didnt measure it till today. Just winged it to see if it makes a difference.

Sent from my SM-N950U using Tapatalk

Douglas Ostrander

Here For The Long Haul!

- Local time

- 3:36 PM

- User ID

- 8

- Joined

- Dec 4, 2015

- Messages

- 867

- Reaction score

- 5,510

- Location

- Waukee Iowa next to I80

Here is pic from other side. I don't file. I grind. OEM settings are 10 degree top plate 10 degree offset and 55 degree tilt. I will try a little more tilt. The 27RX chain is semi chisle. The chain in the pic is after hitting some solid metal. Broke 5 cutters off and filled several with metal shavings. I think the entire 190 drive link chain only has 18 cutters.

Let's see your milling chain.

Sent from my SM-N950U using Tapatalk

Let's see your milling chain.

You need to file deeper into the gullet of the tooth. The hook angle is very shallow even for cross cutting. I like my milling chain too have more hook than cross cut chain. Just my opinion of course.

Sent from my SM-N950U using Tapatalk

Marshy

WFO Cutting

- Local time

- 4:36 PM

- User ID

- 417

- Joined

- Jan 5, 2016

- Messages

- 3,800

- Reaction score

- 13,111

- Location

- Mexico NY

Idk yet. I milled both sides of a 24' long beam from poplar and it seemed to cut well and smooth. I'd have to look it over and try another cut because it didnt seem to dull any. It might not hold up in hard woods like oak. I'm going to mill some pine with it without sharpening and see how it cuts before I take a file to it.

KiwiBro (deleted)

Pinnacle OPE Member

- Local time

- 4:36 PM

- User ID

- 914

- Joined

- Feb 19, 2016

- Messages

- 531

- Reaction score

- 1,616

- Location

- New Zealand

Thanks for keeping us informed. Was that also with the 16-pin rim at 2100RPMs? BIG drop in cut times. With the RX chain I guess chip clearance is less likely to be an issue when you dropped the rakers, given how few cutters it is running.Finally got to try the RX chain with rakers taken way down. Wow. 2 min 30 sec to cut a slab from 8 min with regular rakers. Will be moding the rest of my 196 dl chains.

Cherry!

Sent from my SM-N950U using Tapatalk

Douglas Ostrander

Here For The Long Haul!

- Local time

- 3:36 PM

- User ID

- 8

- Joined

- Dec 4, 2015

- Messages

- 867

- Reaction score

- 5,510

- Location

- Waukee Iowa next to I80

Thanks for keeping us informed. Was that also with the 16-pin rim at 2100RPMs? BIG drop in cut times. With the RX chain I guess chip clearance is less likely to be an issue when you dropped the rakers, given how few cutters it is running.

No still using the 14 pin rim. I forgot to try the 16. Was in a hurry to get some milling done between rain storm. Did four logs and each log had metal inside. From nails to something big. Chain cut the nails but the one log got put back to the firewood pile. Milled bur oak, cherry, and honey locust logs.

Marshy

WFO Cutting

- Local time

- 4:36 PM

- User ID

- 417

- Joined

- Jan 5, 2016

- Messages

- 3,800

- Reaction score

- 13,111

- Location

- Mexico NY

I cut another 30ft linear feet with this chain and still doesnt show any wear. One thing to consider though, I strip the bark from my logs before milling so that might help. Either way. The 30 ft of pine I milled it walked right through on one tank of gas.Does the big hook dull quicker than say a 25* top plate angle? I am trying to figure this stuff out. Lol

hseII

Heef

- Local time

- 4:36 PM

- User ID

- 311

- Joined

- Dec 29, 2015

- Messages

- 6,842

- Reaction score

- 24,460

- Location

- West Georgia

I cut another 30ft linear feet with this chain and still doesnt show any wear. One thing to consider though, I strip the bark from my logs before milling so that might help. Either way. The 30 ft of pine I milled it walked right through on one tank of gas.

We do the same with our Woodmizer if there is any evidence or dirt, gravel, etc.

Not taking any chances & the sharp life is greatly increased.

RI Chevy

Mastermind Approved!

- Local time

- 4:36 PM

- User ID

- 1254

- Joined

- May 7, 2016

- Messages

- 27,002

- Reaction score

- 67,801

- Location

- earth

Excellent tips. Oddly enough, I generally keep a small hatchet with me when I cut downed trees. If I see something I don't like, I swipe off the bark and cut at my 16" length. Lol

Save the chain.

Save the chain.

krustysurfer

Well-Known OPE Member

- Local time

- 4:36 PM

- User ID

- 8061

- Joined

- Dec 7, 2018

- Messages

- 23

- Reaction score

- 45

- Location

- Western Lower Michigan

Thats The Ticket! now if we can use a square file/ grind we will be in the money... physics would say that a smaller cutting tooth/chain would offer the least resistance, so .025 seems to be a possible option ...question is .025 chain strong enough in a milling situation? we would not want to be snapping chain from overloading the links even though my 2511T with .025 cuts so scary fast!This is 27RX milling chain with raker taken down to 0.058. Stock chain is measuring 0.025. Should be 0.030. Didnt measure it till today. Just winged it to see if it makes a difference.

Sent from my SM-N950U using Tapatalk

a 404 is removing a lot of material... is that even necessary?(making lots of sawdust) i can see a triangle or square file for hand filing and a flat edged faced grinding wheel with a bevel on the top edge for proper cutting face angle? my mind is wandering.................... curious minds would like to know!

Last edited:

krustysurfer

Well-Known OPE Member

- Local time

- 4:36 PM

- User ID

- 8061

- Joined

- Dec 7, 2018

- Messages

- 23

- Reaction score

- 45

- Location

- Western Lower Michigan

http://treefalling.com

Yes, follow that link. You dont need to get as anal as this guy but it gives you the info you need and more. I have used a triangular file in the granberg jig with out modifying it in any way. The drawback was trying to get the side plate at the right angle. Once I round the nose of the thumb screws I will be able to roll the file and get the proper side plate angle.

Speaking of hitting metal in trees... I had a PM conversation with this guy and it proved to be interesting. He was in fact looking to be compensated for the trees that knowingly had metal in them.

View attachment 143835