Steve

Excellence!

- Local time

- 10:36 PM

- User ID

- 639

- Joined

- Jan 21, 2016

- Messages

- 8,461

- Reaction score

- 45,478

- Location

- Missouri

Ok, buttoned her back up enough to run and started it. The valve train seems to run smoother, however the miss is still there. I put fresh gas and a whole can of seafoam in it, gonna let it run awhile and see if any improvement.

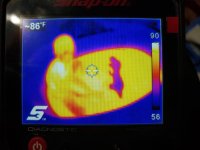

Do you have an IR camera to see if one of the exhaust ports is cooler than the others?