- Local time

- 1:31 PM

- User ID

- 27297

- Joined

- Aug 15, 2023

- Messages

- 67

- Reaction score

- 110

- Location

- Massachusetts

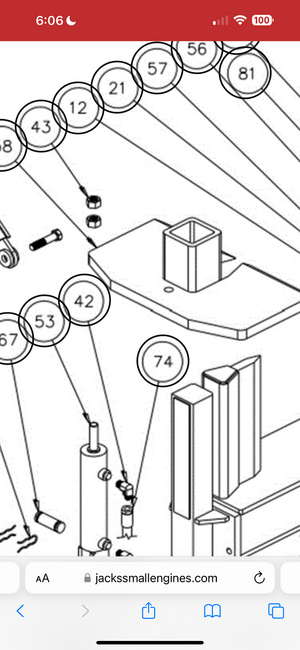

Looks like The previous owner did some welding (I think) the four way wedge pops off every now and again when a big knotty piece pushes it at an upward angle. I don’t think it was originally welded and the piston looks shorter than it’s supposed to be. Not sure if I should weld back on or what would be the best fix. It also has auto cycle but it is very finicky sometimes it works great sometimes it doesn’t work at all and sometimes it half works then stops halfway through not sure if this is fixable or not, seems to pop out of auto cycle very easy for no reason. Lastly has anyone seen a wedge that would fit on here into 2x2 steel if I wanted to change the four way wedge to a six way?