el33t

Super OPE Member

- Local time

- 5:12 PM

- User ID

- 29908

- Joined

- Aug 28, 2024

- Messages

- 277

- Reaction score

- 690

- Location

- Poland

This chain was designed for smoother cutting of smaller limbs and branches: the reduced kickback performance was a surprise result (!).

It is interesting to note that the original Type 91 had neither bumper tie straps nor bumper drive links.

I'm probably starting to get boring in this thread, but is your comparison about full 1/4 or 1/4 extended pitch. IMHO a chain with a smaller pitch with the rest of the same parameters will run smoother. 3/8 LP was introduced to cut costs. Of course a nice side effect is fewer cutters to sharpen.I don't want my bar bouncing around, or vibrating, 10’ in the air.

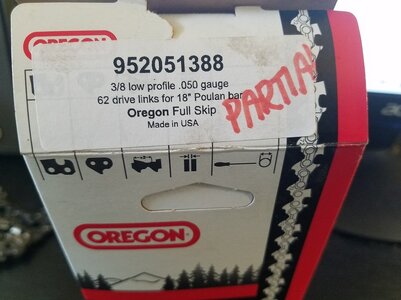

I prefer the 3/8”, low profile over 1/4” or ‘Nano’ chains, because it takes a bigger bite, and there is more cutter to sharpen.

I have tried them, side-by-side in conventional saws.

A true, ‘full house’ sequence would not clear chips as well as standard (‘full complement’), and cut slower: hard on the arm and shoulder muscles.

View attachment 437100

Here I would not be so sure. That would have to be checked. I don't think Techtronic would go to the trouble of equipping their most premium saws of this type with “full-house” chains (Ryobi uses standard chains) if it didn't make sense for this application.

Such chains, due to the higher number of cutter links, are certainly more expensive. I have seen '(full) skip' chains used in cheap saws, both petrol and electric. In my opinion, just to cut costs a bit.

PS

I noticed that you probably meant only “conventional” chainsaws. Here, I agree. There is no point in using 'full-house' chains on such saws.

Last edited: