Philbert

Chainsaw Enthusiast

- Local time

- 4:31 PM

- User ID

- 737

- Joined

- Jan 30, 2016

- Messages

- 4,440

- Reaction score

- 17,937

- Location

- East Dakota

General

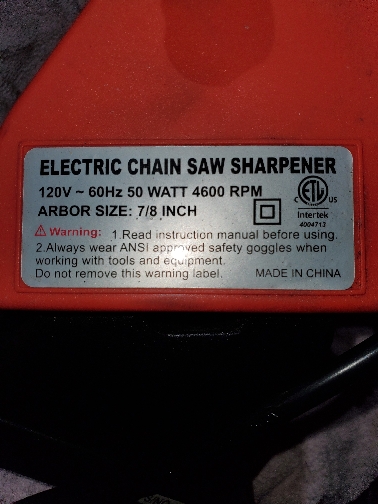

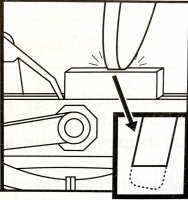

Several years back I was challenged to evaluate some of the less expensive 'mini-grinders' for sharpening saw chain. These grinders typically have 4-1/8 or 4-1/4-inch diameter wheels; fixed head tilt angles; and fairly small (70 to 85 Watt) motors. While limited in angle adjustment and power, they are also compact, quiet, and relatively inexpensive, ranging from about $30 to $80, depending on the model, vendor, etc. They can be a good choice for touching up chains dulled from normal use, or for guys who just don't like to file, providing sharp, consistent cutters at standard angles.

At the lower end, these mini-grinders come with all plastic / composite construction, thin metal components, and a single grinding wheel. The Forester model 04844 comes with a sturdier feeling, cast aluminum base; a heavier gauge chain vise and chain stop; 1/8" and 3/16" grinding wheels; a wheel dressing brick; a plastic wheel / sharpening gauge; and even a spare set of brushes for the motor. It also comes with a fairly clear User's Manual.

This grinder is said to be identical to the Oregon 310-120, except for minor detailing and branding. It feels well finished, and requires only very minor assembly. I also liked the Oregon model, but that one had a few glitches when first released. I assume that those have been addressed, so pricing could be a factor in choosing between the two.

Philbert

Several years back I was challenged to evaluate some of the less expensive 'mini-grinders' for sharpening saw chain. These grinders typically have 4-1/8 or 4-1/4-inch diameter wheels; fixed head tilt angles; and fairly small (70 to 85 Watt) motors. While limited in angle adjustment and power, they are also compact, quiet, and relatively inexpensive, ranging from about $30 to $80, depending on the model, vendor, etc. They can be a good choice for touching up chains dulled from normal use, or for guys who just don't like to file, providing sharp, consistent cutters at standard angles.

At the lower end, these mini-grinders come with all plastic / composite construction, thin metal components, and a single grinding wheel. The Forester model 04844 comes with a sturdier feeling, cast aluminum base; a heavier gauge chain vise and chain stop; 1/8" and 3/16" grinding wheels; a wheel dressing brick; a plastic wheel / sharpening gauge; and even a spare set of brushes for the motor. It also comes with a fairly clear User's Manual.

This grinder is said to be identical to the Oregon 310-120, except for minor detailing and branding. It feels well finished, and requires only very minor assembly. I also liked the Oregon model, but that one had a few glitches when first released. I assume that those have been addressed, so pricing could be a factor in choosing between the two.

Philbert

Last edited: