So.... we all know by now porting 98% of aftmarket cylinders is a waste of time.

(Cheap chrome white box cylinders port the best, but still have issue)

Little back story. Have an event coming up that is racing clone saws 660/372.... Cool, they also have firewood classes 55,65,85cc

So I got the ok to go down a bore size to 52mm and dual enter my 660 clone in the 85cc class and the clone 660 class.

I have had one of those fancy pistons with a chrome ring , I have been wanting to use it for a while now. To run a chrome ring you need a nikasil bore....

So I picked up a meteor, and hyway 650/52mm cylinders.

Both are identical castings. Meteor had harder /shinier plating. But both were nikasil.

Meteor had issues right at the base cut...

Hyway managed to port up ok, using a stone to open the ports.

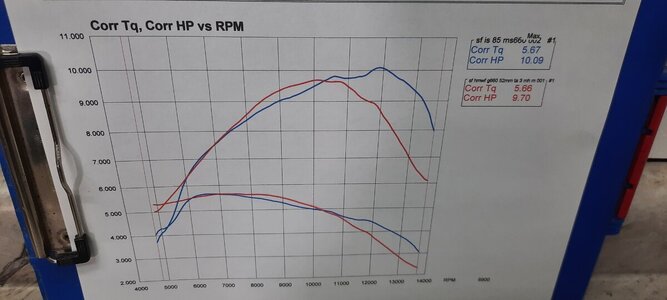

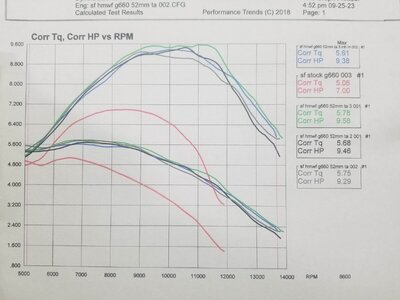

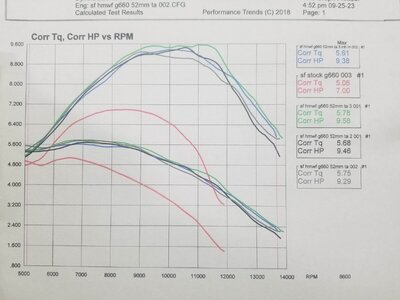

Even made pretty solid power for 85cc aftermarket with no chamber work.

Then I decided to eliminate any questions, and just build a 54mm for the clone 660 and swap this 52mm on my oem 660 for the firewood 85cc class.

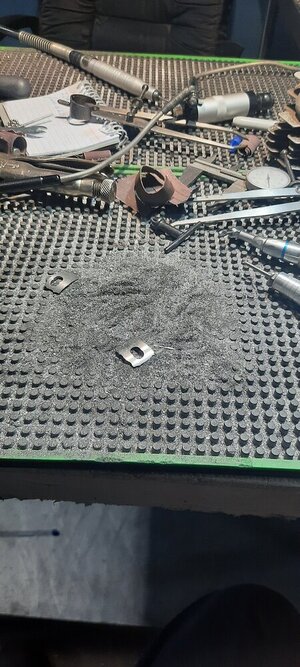

That is when I find...

Plating above the exhaust decided to leave the chat in less than 1 tank....

(Cheap chrome white box cylinders port the best, but still have issue)

Little back story. Have an event coming up that is racing clone saws 660/372.... Cool, they also have firewood classes 55,65,85cc

So I got the ok to go down a bore size to 52mm and dual enter my 660 clone in the 85cc class and the clone 660 class.

I have had one of those fancy pistons with a chrome ring , I have been wanting to use it for a while now. To run a chrome ring you need a nikasil bore....

So I picked up a meteor, and hyway 650/52mm cylinders.

Both are identical castings. Meteor had harder /shinier plating. But both were nikasil.

Meteor had issues right at the base cut...

Hyway managed to port up ok, using a stone to open the ports.

Even made pretty solid power for 85cc aftermarket with no chamber work.

Then I decided to eliminate any questions, and just build a 54mm for the clone 660 and swap this 52mm on my oem 660 for the firewood 85cc class.

That is when I find...

Plating above the exhaust decided to leave the chat in less than 1 tank....