B

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Brewz

Free Range Human in a Tax Farm

- Local time

- 1:23 PM

- User ID

- 550

- Joined

- Jan 16, 2016

- Messages

- 4,217

- Reaction score

- 14,305

- Location

- Hunter Valley - Australia

Here is a thread I started about modifying a Stihl 039 with an MS460 carb.

The initial cut times show it was slower but I still need to do further testing as I recon it can do much better.

Looking at the videos I recon I loaded up the saw more with the 460 carb fitted and slowed it down

http://opeforum.com/threads/ms460-carb-on-an-039.530/

The initial cut times show it was slower but I still need to do further testing as I recon it can do much better.

Looking at the videos I recon I loaded up the saw more with the 460 carb fitted and slowed it down

http://opeforum.com/threads/ms460-carb-on-an-039.530/

Terry Syd

Pinnacle OPE Member

- Local time

- 1:23 PM

- User ID

- 575

- Joined

- Jan 18, 2016

- Messages

- 1,589

- Reaction score

- 5,976

- Location

- Comboyne, NSW Australia

Brewz, I finally found my old HD-5 carb from the 029. I checked it out and remembered I had drilled out the limiter jet in the carb, but I hadn't gotten around to comparing it to the 460 carb. Anyway, I fired up the saw with the modded HD-5, got the idle worked out and then tried to rev it. It wouldn't go past 11,000 rpm, so I went back in and blocked off the auxiliary jet for the high speed needle.

I had put the Works Connection tach on the saw so I could see what rpms it was running. I set it to 13,000 WOT and went cutting wood. The saw will torque down to below 6,000 without bogging and likes to throw big chips at those lower rpms. I tweaked the high speed needle a bit leaner while out cutting.

The stock HD-5 on an 029 (54cc) is supposed to be set to 13,000. The same carb on an 039 (64cc) is suppose to be set at 12,500. The tuning sounds counter intuitive, but what is happening is that on the bigger displacement engine the high speed fuel curve needs to be brought down lower in the rpm band to feed the torque peak. When the limiter is removed and the low speed circuit flowing more, the high speed needle can be leaned back out.

Besides having advanced the ignition timing about 6 degrees, I also built a high-flow air filter for the saw. It uses the old 029 filter (without the compensator port) and the cage has been drilled all the way around. I then glued some thin filter foam around the cage and then sewed a cover around it using an old flannel shirt. Works great.

While out cutting I got the saw good and hot and then ran it WOT until the rpm stabilised, it showed 13,350 on the tach. I then took off the high-flow filter and put on a fresh stock filter (the compensator port was plugged) and did the same experiment. With the stock filter it showed 13,275. It may have only been around 75 rpm difference, but I hadn't cleaned the high-flow filter for the last three times I went cutting - and it still breathed better than a fresh, never used, stock filter.

In other words, running a bigger venturi on one of these saws isn't going to help - the filter is the bottle neck.

The 460 carb not only has a bigger venturi, but the discharge nozzle position is different. The fuel curve for the high speed circuit will be different to the HD-5. However, I think if you leaned out the high speed needle on the 460 carb the fuel curve should flatten out. I think you may be running it too rich with the WOT rpm down at 12,700-800 (that rpm works for a stock HD-5 carb)

Here's something else I noticed, the HD-5 has a stronger metering spring than the 460 carb. In other words, there is a lot of potential in the 460 carb for bigger engines. It has much bigger air bleed/transition holes to start with - put in a stronger metering spring and the low speed circuit could probably flow enough for a 90cc engine. With the bigger venturi and the potential in the low speed circuit, it seems a more logical choice than trying to adapt a WJ to something like a big bore 372.

Now that I have the HD-5 modded, I'll have to run a test to see which carb I prefer.

I had put the Works Connection tach on the saw so I could see what rpms it was running. I set it to 13,000 WOT and went cutting wood. The saw will torque down to below 6,000 without bogging and likes to throw big chips at those lower rpms. I tweaked the high speed needle a bit leaner while out cutting.

The stock HD-5 on an 029 (54cc) is supposed to be set to 13,000. The same carb on an 039 (64cc) is suppose to be set at 12,500. The tuning sounds counter intuitive, but what is happening is that on the bigger displacement engine the high speed fuel curve needs to be brought down lower in the rpm band to feed the torque peak. When the limiter is removed and the low speed circuit flowing more, the high speed needle can be leaned back out.

Besides having advanced the ignition timing about 6 degrees, I also built a high-flow air filter for the saw. It uses the old 029 filter (without the compensator port) and the cage has been drilled all the way around. I then glued some thin filter foam around the cage and then sewed a cover around it using an old flannel shirt. Works great.

While out cutting I got the saw good and hot and then ran it WOT until the rpm stabilised, it showed 13,350 on the tach. I then took off the high-flow filter and put on a fresh stock filter (the compensator port was plugged) and did the same experiment. With the stock filter it showed 13,275. It may have only been around 75 rpm difference, but I hadn't cleaned the high-flow filter for the last three times I went cutting - and it still breathed better than a fresh, never used, stock filter.

In other words, running a bigger venturi on one of these saws isn't going to help - the filter is the bottle neck.

The 460 carb not only has a bigger venturi, but the discharge nozzle position is different. The fuel curve for the high speed circuit will be different to the HD-5. However, I think if you leaned out the high speed needle on the 460 carb the fuel curve should flatten out. I think you may be running it too rich with the WOT rpm down at 12,700-800 (that rpm works for a stock HD-5 carb)

Here's something else I noticed, the HD-5 has a stronger metering spring than the 460 carb. In other words, there is a lot of potential in the 460 carb for bigger engines. It has much bigger air bleed/transition holes to start with - put in a stronger metering spring and the low speed circuit could probably flow enough for a 90cc engine. With the bigger venturi and the potential in the low speed circuit, it seems a more logical choice than trying to adapt a WJ to something like a big bore 372.

Now that I have the HD-5 modded, I'll have to run a test to see which carb I prefer.

sawnami

Here For The Long Haul!

- Local time

- 11:23 PM

- User ID

- 619

- Joined

- Jan 20, 2016

- Messages

- 1,818

- Reaction score

- 11,825

- Location

- Springfield

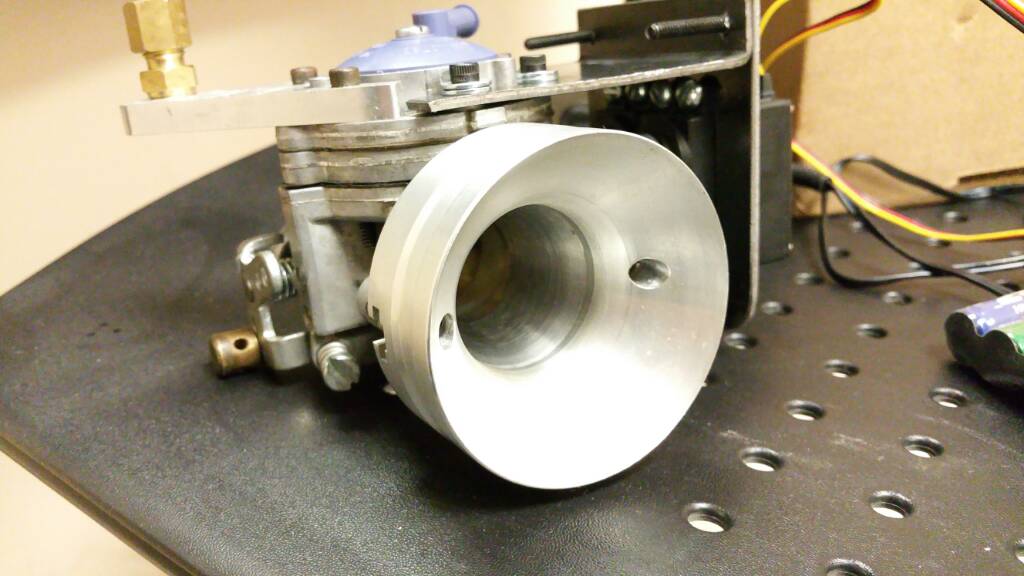

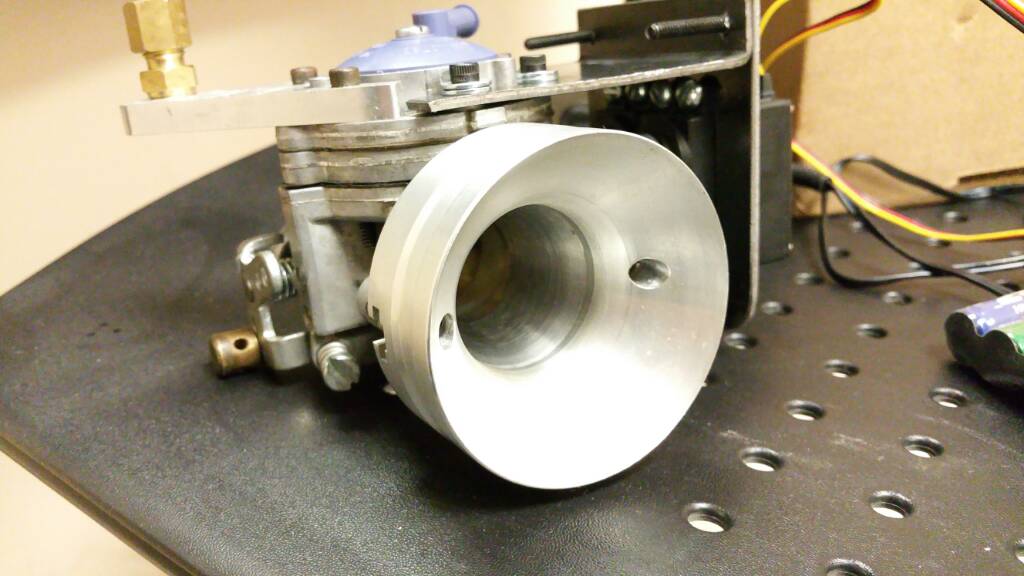

A friend's Tilly that he's working on.

Sent from my SM-N910V

Sent from my SM-N910V

Terry Syd

Pinnacle OPE Member

- Local time

- 1:23 PM

- User ID

- 575

- Joined

- Jan 18, 2016

- Messages

- 1,589

- Reaction score

- 5,976

- Location

- Comboyne, NSW Australia

Here's the best manual I've found for tuning diaphragm carbs. Virtually everything else on the 'net and in 'how-to' manuals has heaps of errors. The Mikuni folks have done it right - http://www.mikuni.com/pdf/sbn_manual.pdf

The circuits on Walbros are different than the circuits on Zamas. For the Zama, the low speed needle only adjusts the idle mixture (like on the Mikuni). Whereas the Walbro, when you tweak the low speed needle it changes the mixture in the entire low speed circuit. For the Zama you have to drill the jets to increase the flow in the low speed circuit (like the Mikuni but with replaceable jets)

There's advantages and disadvantages between Walbro and Zama. Having said that, I'd rather see a diaphragm carb built along the lines of the Mikuni so that it would be much easier to tune. However, with an understanding of how each of the carbs work, you can tweak these simple carbs so that they work quite well.

Bottom line, with a bit of carb work, I'd rather have a simple easy to maintain carb that I can work on with a screwdriver than a new electronic whiz bang computer carb.

The circuits on Walbros are different than the circuits on Zamas. For the Zama, the low speed needle only adjusts the idle mixture (like on the Mikuni). Whereas the Walbro, when you tweak the low speed needle it changes the mixture in the entire low speed circuit. For the Zama you have to drill the jets to increase the flow in the low speed circuit (like the Mikuni but with replaceable jets)

There's advantages and disadvantages between Walbro and Zama. Having said that, I'd rather see a diaphragm carb built along the lines of the Mikuni so that it would be much easier to tune. However, with an understanding of how each of the carbs work, you can tweak these simple carbs so that they work quite well.

Bottom line, with a bit of carb work, I'd rather have a simple easy to maintain carb that I can work on with a screwdriver than a new electronic whiz bang computer carb.

paragonbuilder

Mastermind Approved!

- Local time

- 11:23 PM

- User ID

- 384

- Joined

- Jan 2, 2016

- Messages

- 9,229

- Reaction score

- 33,865

- Location

- Norwich, CT

Very interesting article Terry.

So on a saw, how do I know metering lever height is correct? Or spring?

I've got a freshly rebuilt stock ms260 that bogs a little off idle. I can't tune it out. I tried an aftermarket carb and it runs the same???

Sent from my iPhone using Tapatalk

So on a saw, how do I know metering lever height is correct? Or spring?

I've got a freshly rebuilt stock ms260 that bogs a little off idle. I can't tune it out. I tried an aftermarket carb and it runs the same???

Sent from my iPhone using Tapatalk

paragonbuilder

Mastermind Approved!

- Local time

- 11:23 PM

- User ID

- 384

- Joined

- Jan 2, 2016

- Messages

- 9,229

- Reaction score

- 33,865

- Location

- Norwich, CT

I think it's a lean bog, but richening up the low doesn't help.Lean bog or rich bog?

It doesn't effect running it. It's just a quick bog. Then it revs up fine.

I may just be too used to my huskys snappiness and ported saws???

I need to try my dads 260 and compare.

But it would be nice if I could figure it out ...

paragonbuilder

Mastermind Approved!

- Local time

- 11:23 PM

- User ID

- 384

- Joined

- Jan 2, 2016

- Messages

- 9,229

- Reaction score

- 33,865

- Location

- Norwich, CT

Ok, do you have any thoughts? It tuned out to 14k, and starts right up, idles great, cuts decent, just has that bog?

Sent from my iPhone using Tapatalk

Sent from my iPhone using Tapatalk

Terry Syd

Pinnacle OPE Member

- Local time

- 1:23 PM

- User ID

- 575

- Joined

- Jan 18, 2016

- Messages

- 1,589

- Reaction score

- 5,976

- Location

- Comboyne, NSW Australia

If it is a lean bog, you may be able to tweak the carb with a weaker metering spring. If you have some other carbs, check the springs and find one that is weaker (thinner wire and/or wound tighter) or one that is just shorter.

What you are trying to do is ramp in the fuel flow faster as the throttle valve opens. If the weaker spring makes the problem worse, then it is a rich bog and you will need to find a stronger spring.

You may find if you keep working with the carb that you prefer a stronger spring with the low speed needle out a bit further. With the low speed circuit flowing a bit more, you may have a bit more resistance to bogging when you load the saw. However, you will need the stronger metering spring to lean out the idle and ramp the fuel in slower.

What you are trying to do is ramp in the fuel flow faster as the throttle valve opens. If the weaker spring makes the problem worse, then it is a rich bog and you will need to find a stronger spring.

You may find if you keep working with the carb that you prefer a stronger spring with the low speed needle out a bit further. With the low speed circuit flowing a bit more, you may have a bit more resistance to bogging when you load the saw. However, you will need the stronger metering spring to lean out the idle and ramp the fuel in slower.

CR888

Here For The Long Haul!

- Local time

- 1:23 PM

- User ID

- 452

- Joined

- Jan 9, 2016

- Messages

- 2,622

- Reaction score

- 10,582

- Location

- Australia

A box of oem Walbro metering springs can be had for $59, usually its something a dealer would buy who services OPE. However while its a dear little sectioned box of various springs its a good investment for a keen tuner. That coupled with the 500:500 Walbro tool kit and the pop off pressure gauge with medical style hand pump are good for carb tuning. Then as per Terry's recomendation the twin little tubes of JB weld and some cheap ebay micro drills/pin vise will get anyone started with that you need for proper carb tweaks. Often guys happily throw a 'bad' carb in the trash can with a strong arm as its frustrated them.....don't do this as any carb is full of spare parts that are not the root cause of that carbs problem, this is also a good way to build up a bank of various springs and parts. Terry has a great knowledge on these little cube diaphram carbs and is happy to talk carbs and share his knowledge on all from the air filter to intake port!

paragonbuilder

Mastermind Approved!

- Local time

- 11:23 PM

- User ID

- 384

- Joined

- Jan 2, 2016

- Messages

- 9,229

- Reaction score

- 33,865

- Location

- Norwich, CT

It's bone stock.What's the intake at?

Similar threads

- Replies

- 39

- Views

- 2K