Farmer_Nate

Well-Known OPE Member

- Local time

- 6:46 AM

- User ID

- 25992

- Joined

- Jan 23, 2023

- Messages

- 46

- Reaction score

- 105

- Location

- KY near Frankfort

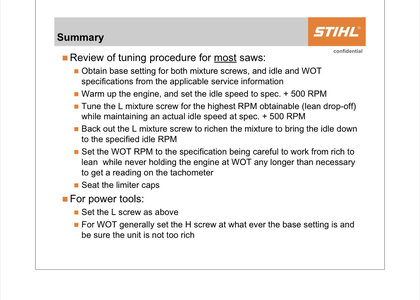

I watched a video of everybody's favorite man, Billy Ray Bucker, or whatever about saw tuning. The man is funny and a little goofy, but his tip about carb tuning the low jet I think was right on and helped me a bunch.

I used his tip to fine tune my old 266xp. The main thing he noted was that it is important to get the idle speed set screw positioned so that it just touches the butterfly throttle plate stop thingy to hold open the butterfly valve the least bit. The low jet should then be adjusted the normal way by listening for idle speed to kick up as the screw is adjusted. Don't crank in that idle speed screw. And make L a bit lean at idle. He made a great point that if the idle jet is set too rich, when the throttle trigger is punched the saw has to burn that extra bit of fuel first before it can get the saw going. We have all heard that little bog, then acceleration upon giving the saw throttle. That hesitation is no good. Is point was if the idle screw is just holding the butterfly open a hair, and the L screw is a bit lean, the best throttle response is attained. I tried it and boy do I like it.

The saw runs way differently now.

Of course I still have the H screw set for warbling under no load, 4-strokin', and then smooth clean-up sound under load in the wood.

The key was getting the L set with as little idle screw engagement as possible. Many people don't consider the position of the idle set screw when adjusting L.

I used his tip to fine tune my old 266xp. The main thing he noted was that it is important to get the idle speed set screw positioned so that it just touches the butterfly throttle plate stop thingy to hold open the butterfly valve the least bit. The low jet should then be adjusted the normal way by listening for idle speed to kick up as the screw is adjusted. Don't crank in that idle speed screw. And make L a bit lean at idle. He made a great point that if the idle jet is set too rich, when the throttle trigger is punched the saw has to burn that extra bit of fuel first before it can get the saw going. We have all heard that little bog, then acceleration upon giving the saw throttle. That hesitation is no good. Is point was if the idle screw is just holding the butterfly open a hair, and the L screw is a bit lean, the best throttle response is attained. I tried it and boy do I like it.

The saw runs way differently now.

Of course I still have the H screw set for warbling under no load, 4-strokin', and then smooth clean-up sound under load in the wood.

The key was getting the L set with as little idle screw engagement as possible. Many people don't consider the position of the idle set screw when adjusting L.

Last edited: