- Local time

- 7:06 AM

- User ID

- 297

- Joined

- Dec 28, 2015

- Messages

- 5,215

- Reaction score

- 34,366

- Location

- Central Ohio

Please do not comment in this thread unless you are giving a review of your own JMSSaw.

I am a long-winded gasbag and it make take me a bit to make this complete and accurate.

I was an early proponent of Jason Stratton ie. JMSSaws. I considered him a good friend for a long time.

I will be as dispassionate as I can be in this review.

I like/love ported saws and at some point a couple/few years ago I had a few of them from Brad and Randy and decided to try out some other flavors. I sell chainsaw parts online and its always great to meet like minded saw maniacs and ported saws are a great way to meet new people at get-togethers.

Saw #1

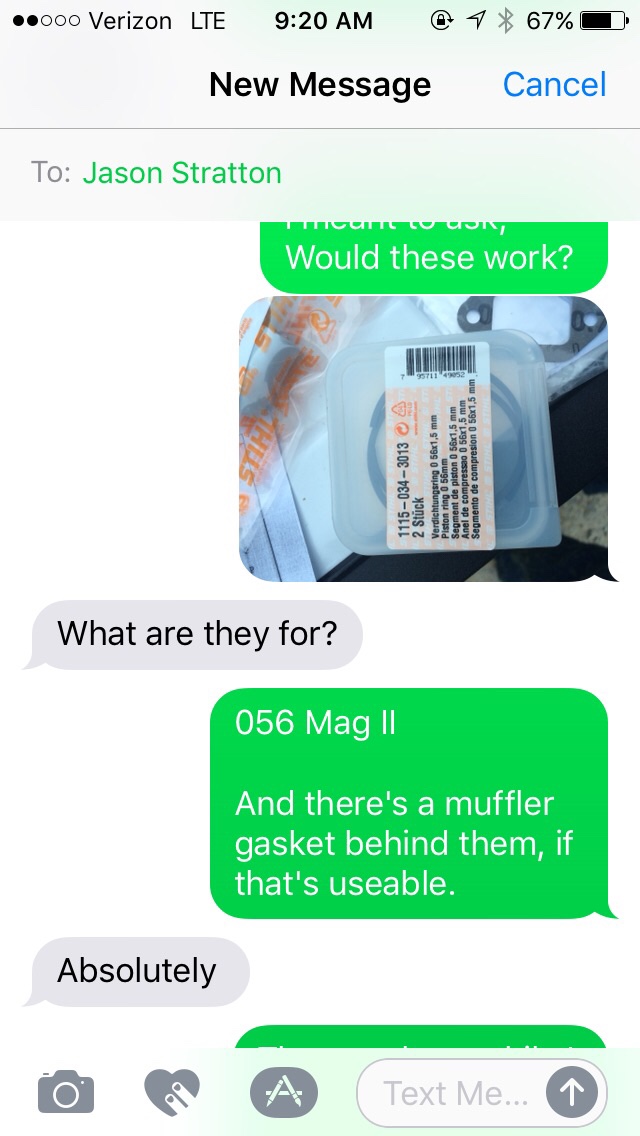

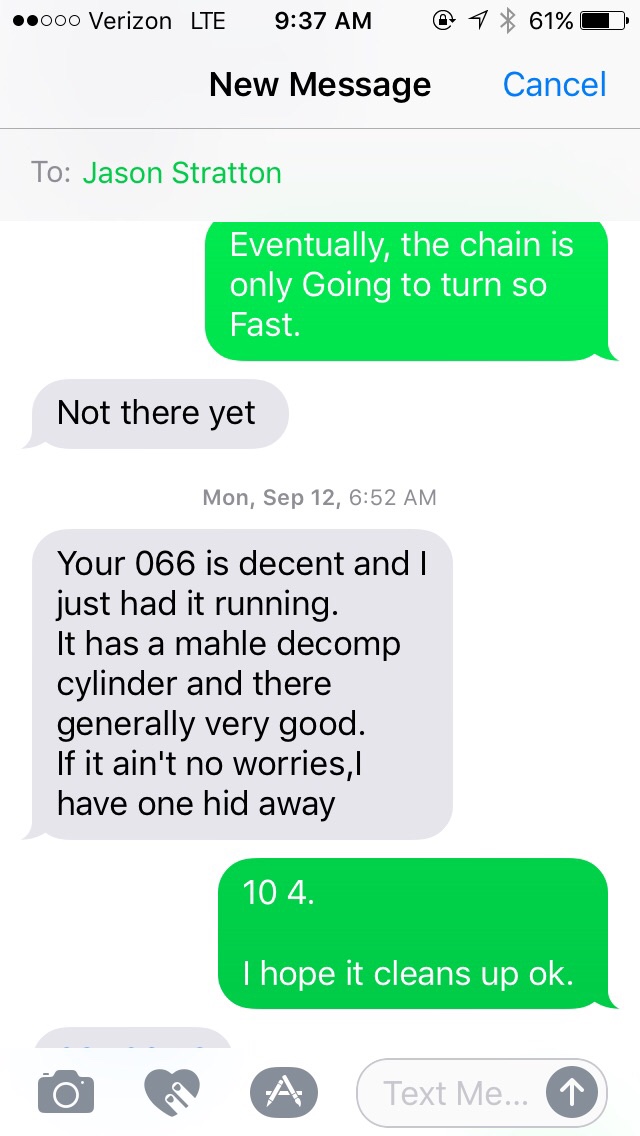

I don't remember how I stumbled across Jason but I think it was on Arboristsite and we struck up a deal for him to port a brand new MS660 cylinder and put it on a running 064 I had purchased from Joe earlier that year.

The saw was a good strong runner and complete. I provided the new OEM cylinder kit as well.

The price was about in line with what I had paid to have other saws ported.

I don't remember anything particularly odd or bad about the transaction other than it taking eternity to get the saw. I have no real recollection of how long it took but I do know I had been invited to a GTG north of me with a bunch of fast saw guys and I was planning to take this saw to swing around like a mighty phallus and impress them all. Well it was way too late and probably a good thing because those guys would have eaten my cheese and taken my lunch money

Several of those guys had been reading his posts on the forums and told me he was a giant bag of squid scrotums, but I didn't listen because every man likes to think he knows it all and is a great judge of character. *f-wordin' Hubris makes us blind. I am not immune.

I don't think I complained about the slow shipping, I mean he lives on 700 acres in the middle of nowhere so mail service is slow.

Jason did post pictures of the cylinder on forums after telling me it was already ported and very nicely done. Turns out Joe had ported it but not enough that he felt it was worth charging me for and I didn't know it. I thought posting pics of someone else's work was uncool, but I didn't say anything because we didn't know who did the work at the time.

I didn't get back the original good piston and cylinder when the saw came back, but I didn't say anything, figured it didn't matter that much.

The first time I ran it other than a few test cuts at home was at the spring NY GTG 2016.

It ran fantastic and in fact it was faster than the 066 that Bret and Josh ran.

I was had over heels in love with the saw at that point. Several guys ran it and it was impressive.

It ran out of gas and I re-fuelled it for Mustang Mike to give it a try and it wouldn't restart.

I teased him about breaking my saw but started looking and found one of the packing peanuts underneath the kill switch (that's how it got it's name) and I was able to get it to start but again when Mike tried to fire it, it wouldn't start. I put it away and went on to do more goofing around with the hundreds of saws that were there.

Once back at home I looked inside and the piston was scored big time. So I pulled the cylinder and there was no wrist pin bearing. None... but the entire bottom end was covered in fine black dust almost like graphite.

The cylinder looked fine.

Thinking back I seem to remember that there were also a few bits of ground metal and little globs in the case.

It turns out that he had used an aftermarket piston pin bearing and it had disintegrated.

I remember flushing the case out with fuel many times and straining through cloth till it was clean, but I honestly don't remember if I split the case and changed the bearings or not.

At the time there was a thread and guys were going both ways on how to deal with it.

I figured "*s-word-happens" and I replaced with a new OEM piston and lightly cleaned the cylinder even though it was virtually unmarked. I re-assembled the saw and ran it in wood, all seemed good. I think it went to several GTG with me since and has run maybe another tank or two of gas since the new piston and OEM piston bearing I installed.

With all of the controversy swirling around, I decided to pull the top end on Peanut today to make sure everything was good to go so I can sell the saw. Not because of how it runs, which is fantastic but because I don't do ANY work with chainsaws and I am thinning the herd to just the shelf queens and race saws.

Despite all the grumbling and moaning by other customers I guess I was hoping that my saws were all good.

that doesn't look good

there are light vertical lines in the cylinder, the inside of the crankcase is clean

This may be my fault, i may not have split the case and there may have been something left down in there, the pattern to the intake and exhaust scoring is odd to me.

And again this saw is a runner.

At this point I guess I will check the threads in the case and put an 066 cylinder kit on it after splitting the bottom end and doing new bearings and seals.

I will also fix the stripped threads on one of the tp cover holes, which ma or may not have been there originally.

I am curious how true this base is as well, it didn't matter to me before because the saw kicked ass but now...

looks like a non-lathe jobber to me

the marks in the top of the cylinder were probably from the early failure and I cleaned the jug in ultrasonic but maybe I should have replaced it?

I am a long-winded gasbag and it make take me a bit to make this complete and accurate.

I was an early proponent of Jason Stratton ie. JMSSaws. I considered him a good friend for a long time.

I will be as dispassionate as I can be in this review.

I like/love ported saws and at some point a couple/few years ago I had a few of them from Brad and Randy and decided to try out some other flavors. I sell chainsaw parts online and its always great to meet like minded saw maniacs and ported saws are a great way to meet new people at get-togethers.

Saw #1

I don't remember how I stumbled across Jason but I think it was on Arboristsite and we struck up a deal for him to port a brand new MS660 cylinder and put it on a running 064 I had purchased from Joe earlier that year.

The saw was a good strong runner and complete. I provided the new OEM cylinder kit as well.

The price was about in line with what I had paid to have other saws ported.

I don't remember anything particularly odd or bad about the transaction other than it taking eternity to get the saw. I have no real recollection of how long it took but I do know I had been invited to a GTG north of me with a bunch of fast saw guys and I was planning to take this saw to swing around like a mighty phallus and impress them all. Well it was way too late and probably a good thing because those guys would have eaten my cheese and taken my lunch money

Several of those guys had been reading his posts on the forums and told me he was a giant bag of squid scrotums, but I didn't listen because every man likes to think he knows it all and is a great judge of character. *f-wordin' Hubris makes us blind. I am not immune.

I don't think I complained about the slow shipping, I mean he lives on 700 acres in the middle of nowhere so mail service is slow.

Jason did post pictures of the cylinder on forums after telling me it was already ported and very nicely done. Turns out Joe had ported it but not enough that he felt it was worth charging me for and I didn't know it. I thought posting pics of someone else's work was uncool, but I didn't say anything because we didn't know who did the work at the time.

I didn't get back the original good piston and cylinder when the saw came back, but I didn't say anything, figured it didn't matter that much.

The first time I ran it other than a few test cuts at home was at the spring NY GTG 2016.

It ran fantastic and in fact it was faster than the 066 that Bret and Josh ran.

I was had over heels in love with the saw at that point. Several guys ran it and it was impressive.

It ran out of gas and I re-fuelled it for Mustang Mike to give it a try and it wouldn't restart.

I teased him about breaking my saw but started looking and found one of the packing peanuts underneath the kill switch (that's how it got it's name) and I was able to get it to start but again when Mike tried to fire it, it wouldn't start. I put it away and went on to do more goofing around with the hundreds of saws that were there.

Once back at home I looked inside and the piston was scored big time. So I pulled the cylinder and there was no wrist pin bearing. None... but the entire bottom end was covered in fine black dust almost like graphite.

The cylinder looked fine.

Thinking back I seem to remember that there were also a few bits of ground metal and little globs in the case.

It turns out that he had used an aftermarket piston pin bearing and it had disintegrated.

I remember flushing the case out with fuel many times and straining through cloth till it was clean, but I honestly don't remember if I split the case and changed the bearings or not.

At the time there was a thread and guys were going both ways on how to deal with it.

I figured "*s-word-happens" and I replaced with a new OEM piston and lightly cleaned the cylinder even though it was virtually unmarked. I re-assembled the saw and ran it in wood, all seemed good. I think it went to several GTG with me since and has run maybe another tank or two of gas since the new piston and OEM piston bearing I installed.

With all of the controversy swirling around, I decided to pull the top end on Peanut today to make sure everything was good to go so I can sell the saw. Not because of how it runs, which is fantastic but because I don't do ANY work with chainsaws and I am thinning the herd to just the shelf queens and race saws.

Despite all the grumbling and moaning by other customers I guess I was hoping that my saws were all good.

that doesn't look good

there are light vertical lines in the cylinder, the inside of the crankcase is clean

This may be my fault, i may not have split the case and there may have been something left down in there, the pattern to the intake and exhaust scoring is odd to me.

And again this saw is a runner.

At this point I guess I will check the threads in the case and put an 066 cylinder kit on it after splitting the bottom end and doing new bearings and seals.

I will also fix the stripped threads on one of the tp cover holes, which ma or may not have been there originally.

I am curious how true this base is as well, it didn't matter to me before because the saw kicked ass but now...

looks like a non-lathe jobber to me

the marks in the top of the cylinder were probably from the early failure and I cleaned the jug in ultrasonic but maybe I should have replaced it?