Stefanseiner

Well-Known OPE Member

- Local time

- 8:32 AM

- User ID

- 10487

- Joined

- Sep 18, 2019

- Messages

- 51

- Reaction score

- 176

- Location

- Germany

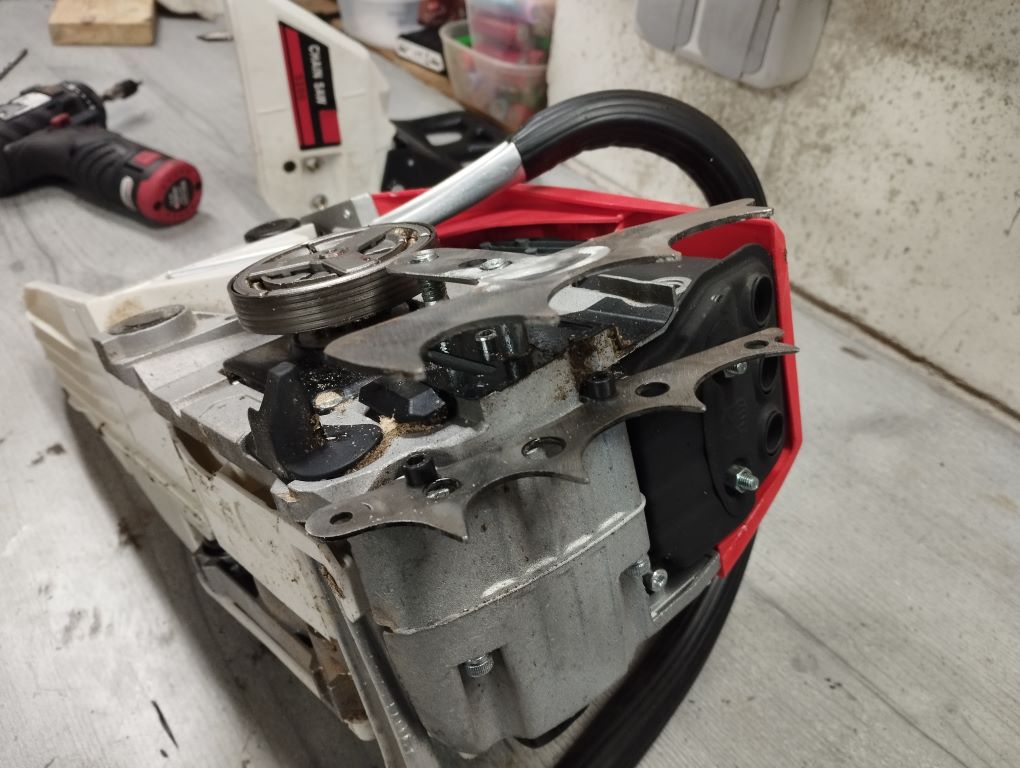

meanwhile I did some modifications on a cheap chinese 52cc saw I bought on eBay before christmas

works done so far:

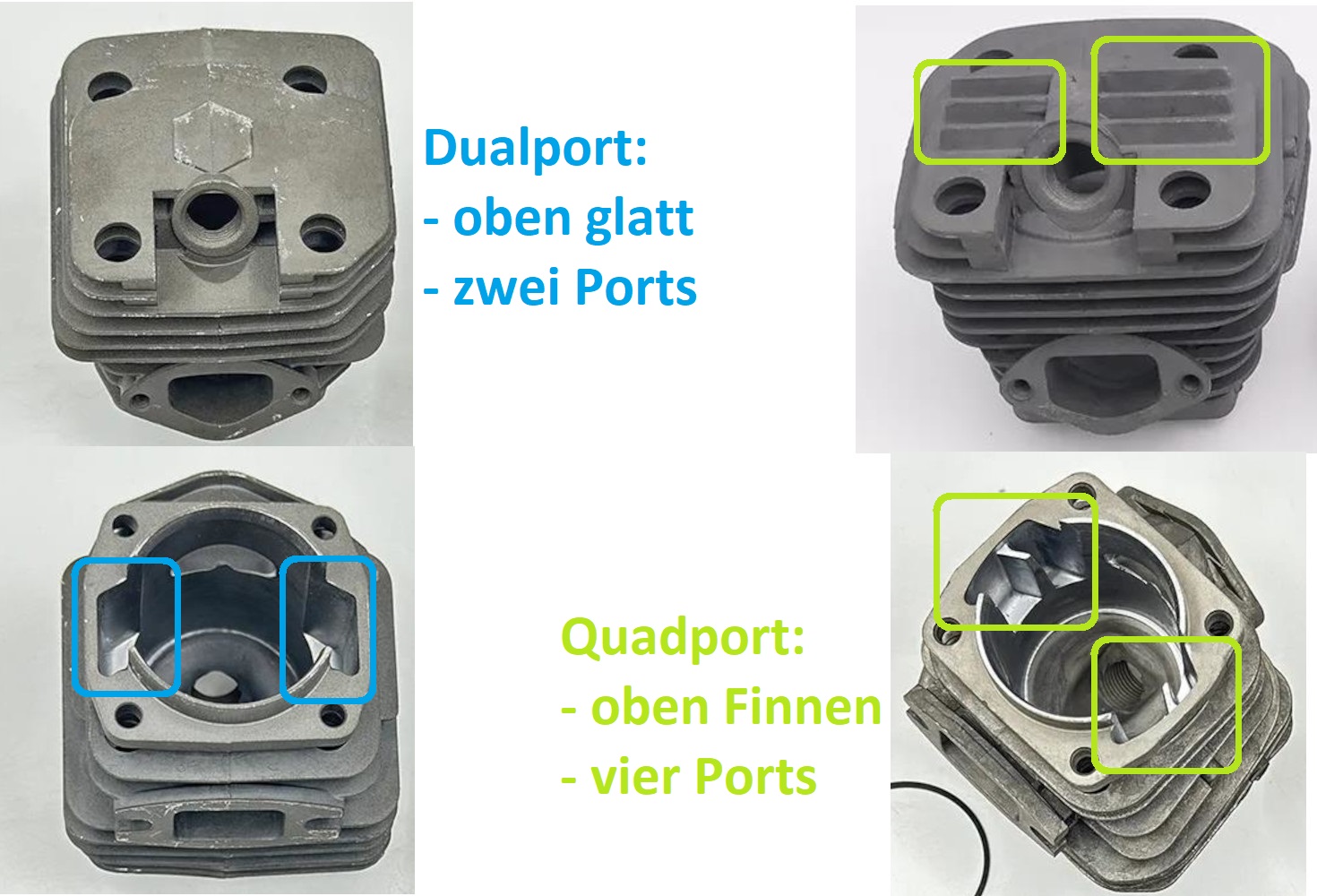

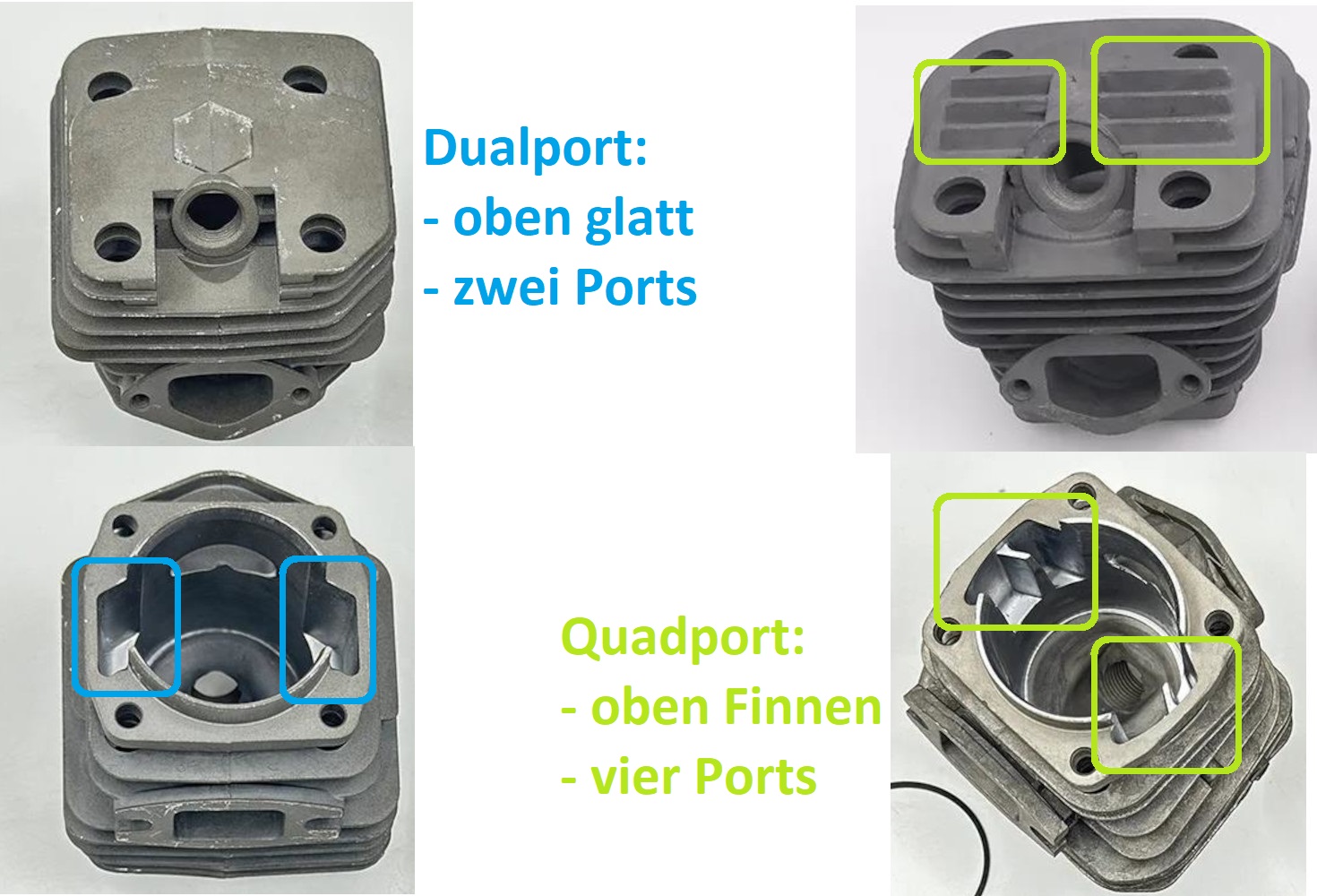

1. changed the orig. dual port cylinder to the better quad port version (higher agility, higher rpm at stock possible, higher torque)

2. Muffler mod (drilled the internal diffusor with bigger 16mm hole, bigger outlet ports with 15mm)

3. thinner gasket seal 0,15mm (original is 0,50mm)

4. paper air filter with ported intake

5. bigger carburator from an 372XP (with 3d-printed manifold to fit it)

left the dualport version, right the quad port

muffler mod, here without the paint

widened air filter intake

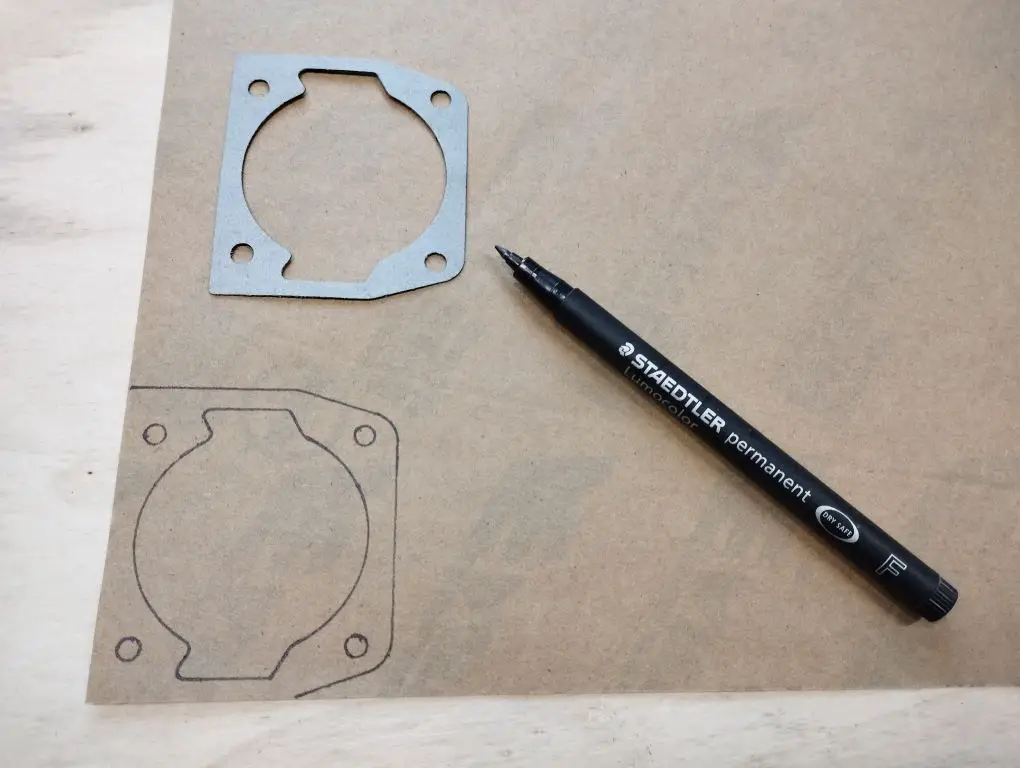

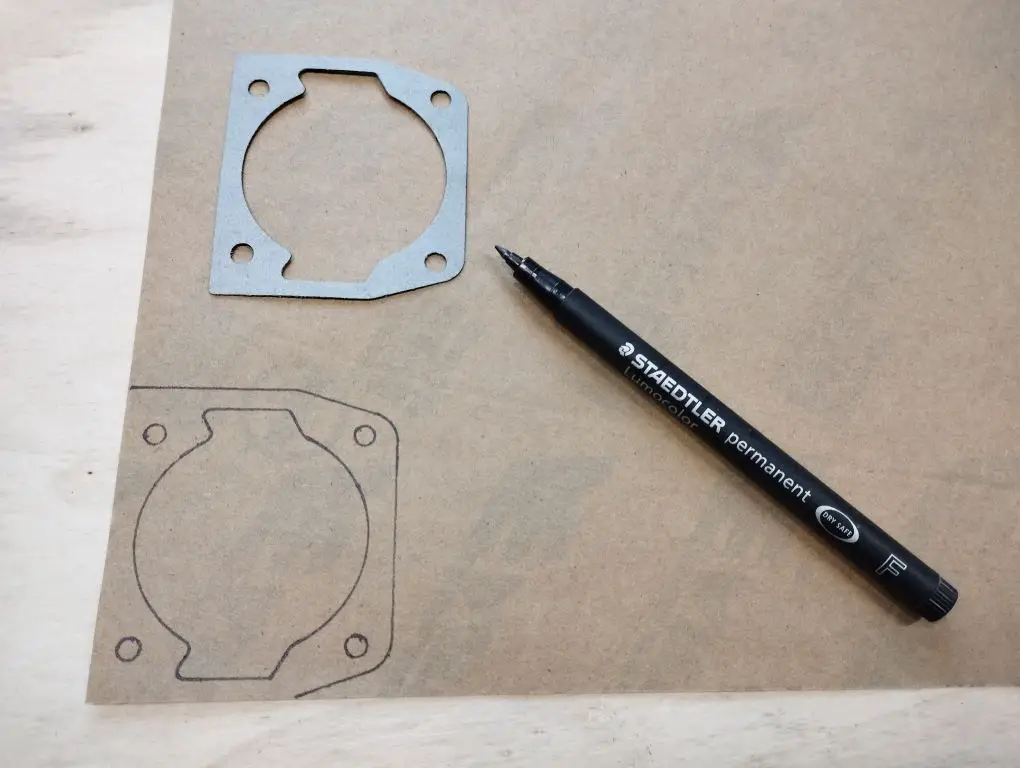

I made the base gasket out of 0,15mm gasket paper

modified 372xp carb. It's a little hard to tune at the chinese chainsaw, I have to raise the idle screw at maximum so the engine will not die when letting the throttle go after full speed

side-gapped spark plug

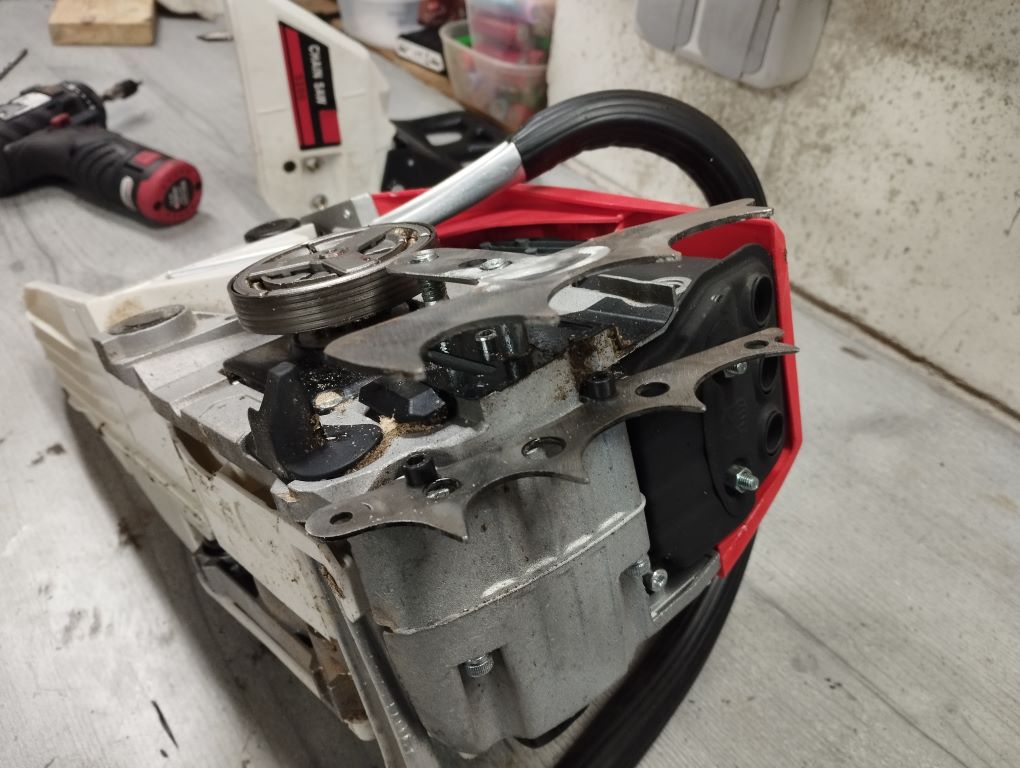

just for fun: adapting some 372XP felling hounds to the chinese saw

and I will try to have the look of the Holzfforma Pro for my cheap chinese saw by foiling some parts with carbon look foil

but honestly I am not happy with this work and maybe I will try to do this again with hydro dipping but this is new for me too.

I did some cuts at the same wood and stopped the time. The timings are for:

1. stock

2. cylinder change + muffler + base gasket + paper air filter

3. carburator + spark plug

actually I am working on porting the cylinder.

Because this is my very first try I used the "old" dual port cylinder, What I've done:

-widened the intake (just left and right, no timing changes in high / depth)

- widened the exhaust outlet (just left and right, no timing changes in high / depth)

- widened the transfers

- polishing the exhaust outlet

yesterday I tried the cylinder in the wood but the cutting times are getting worse (38sec instead of 35sec before).

I guess it's because I did some mistakes while porting by slipping away with the dremel and hitting the cylinder coating.

Or because I was not able to do a better carb tuning. The cutting felt like the saw wanted more fuel and I tried to adjust the carb more rich but then the engine will die after full power.

What do you think?

Next try will be to port the good quadport cylinder and be more careful with the dremel in particular when working with the rotating direction,

but I would also like to figure out what's the problem with my first porting job at the dual port cylinder

works done so far:

1. changed the orig. dual port cylinder to the better quad port version (higher agility, higher rpm at stock possible, higher torque)

2. Muffler mod (drilled the internal diffusor with bigger 16mm hole, bigger outlet ports with 15mm)

3. thinner gasket seal 0,15mm (original is 0,50mm)

4. paper air filter with ported intake

5. bigger carburator from an 372XP (with 3d-printed manifold to fit it)

left the dualport version, right the quad port

muffler mod, here without the paint

widened air filter intake

I made the base gasket out of 0,15mm gasket paper

modified 372xp carb. It's a little hard to tune at the chinese chainsaw, I have to raise the idle screw at maximum so the engine will not die when letting the throttle go after full speed

side-gapped spark plug

just for fun: adapting some 372XP felling hounds to the chinese saw

and I will try to have the look of the Holzfforma Pro for my cheap chinese saw by foiling some parts with carbon look foil

but honestly I am not happy with this work and maybe I will try to do this again with hydro dipping but this is new for me too.

I did some cuts at the same wood and stopped the time. The timings are for:

1. stock

2. cylinder change + muffler + base gasket + paper air filter

3. carburator + spark plug

actually I am working on porting the cylinder.

Because this is my very first try I used the "old" dual port cylinder, What I've done:

-widened the intake (just left and right, no timing changes in high / depth)

- widened the exhaust outlet (just left and right, no timing changes in high / depth)

- widened the transfers

- polishing the exhaust outlet

yesterday I tried the cylinder in the wood but the cutting times are getting worse (38sec instead of 35sec before).

I guess it's because I did some mistakes while porting by slipping away with the dremel and hitting the cylinder coating.

Or because I was not able to do a better carb tuning. The cutting felt like the saw wanted more fuel and I tried to adjust the carb more rich but then the engine will die after full power.

What do you think?

Next try will be to port the good quadport cylinder and be more careful with the dremel in particular when working with the rotating direction,

but I would also like to figure out what's the problem with my first porting job at the dual port cylinder

Last edited: