ZeroPoint

OPE Member

I've been having a sorta gremlin issue with my snowblower because everywhere I turn the problem isn't apparent and then the second I try to start it again it comes back.

Backstory:

The snowblower was used in a residential driveway from the 60's when it was purchased up to around 2003. It ran for the final time in 2006 and then sat, I got it running again and everything seemed fine. Last winter came and I tried to fire it up and it kicked at me one time but I managed to hang onto the cord since the engine was cold and barely fired. The pull start stopped retracting and due to lack of parts that's the last time it ran for the season. This year I was on the internet as one is and I found a guy selling a recoil starter in it's original box from the 70's and decided to try it again.

I figured it would be fine I got the starter and it decided to kick back at me every time I would pull the cord. This is the work I've done so far:

-Replaced the head gasket(blown)

-Pulled the flywheel off and inspected the key found it to be okay but replaced it anyway.

-Checked the points they were perfectly in spec at 0.019".

-Checked the valves as per manual, they were perfectly in spec as well.

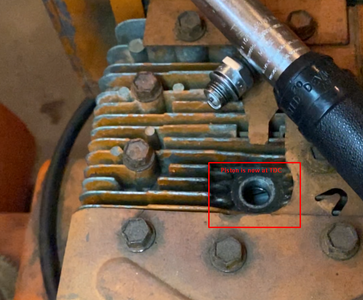

-I checked the air gap coil to flywheel and found one side at 0.009" and the other side at 0.011" when spec is around 0.020" which I adjusted and set to that spec and verified.

Put it all back together tried to fire it up last Friday and it kicked back so hard it ripped the cord out of my hand and slammed the cord all the way back into the housing. This resembles a timing issue since it's preignition. I've worked with small engine shops they're confused. Anyone with any insight into these motors, anything you have to say is appreciated even if it doesn't bring me closer to solving the problem, I want to hear from you.

Briggs Model: 190402-0653-01

Backstory:

The snowblower was used in a residential driveway from the 60's when it was purchased up to around 2003. It ran for the final time in 2006 and then sat, I got it running again and everything seemed fine. Last winter came and I tried to fire it up and it kicked at me one time but I managed to hang onto the cord since the engine was cold and barely fired. The pull start stopped retracting and due to lack of parts that's the last time it ran for the season. This year I was on the internet as one is and I found a guy selling a recoil starter in it's original box from the 70's and decided to try it again.

I figured it would be fine I got the starter and it decided to kick back at me every time I would pull the cord. This is the work I've done so far:

-Replaced the head gasket(blown)

-Pulled the flywheel off and inspected the key found it to be okay but replaced it anyway.

-Checked the points they were perfectly in spec at 0.019".

-Checked the valves as per manual, they were perfectly in spec as well.

-I checked the air gap coil to flywheel and found one side at 0.009" and the other side at 0.011" when spec is around 0.020" which I adjusted and set to that spec and verified.

Put it all back together tried to fire it up last Friday and it kicked back so hard it ripped the cord out of my hand and slammed the cord all the way back into the housing. This resembles a timing issue since it's preignition. I've worked with small engine shops they're confused. Anyone with any insight into these motors, anything you have to say is appreciated even if it doesn't bring me closer to solving the problem, I want to hear from you.

Briggs Model: 190402-0653-01