You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

3D printer

- Thread starter Motorka

- Start date

- Local time

- 11:01 PM

- User ID

- 714

- Joined

- Jan 28, 2016

- Messages

- 4,082

- Reaction score

- 29,103

- Location

- Dike, Iowa

I have a Lulzbot TAZ 6 filament type printer. In order for me to make a part with my 3D printer I have to start with a suitable drawing, in my case I need an .STL file. Then it is a matter of laying the part out in order to get the best orientation of the the layers so the part will have the best structural integrity. Parts with hollow areas may require the addition of supports that can later be removed, but the filament printers can't really print anything in mid-air.

Some small gaps can work, for example the grid on these sawdust screens used on the McCulloch 10 Series saws.

Parts that can be printed flat on the build surface are pretty easy.

Some parts require an elaborate system of supports to obtain good results. This airbox cover for the 300 Series McCulloch saws must be printed at about a 45° angle to align the "grain" in an appropriate direction so the finished part has acceptable strength.

All of that support under the piece is pealed off and thrown away.

There are other types of printers out there, and some with much greater capabilities that what I have but I have been able to turn out a number of decent parts with what I have.

Mark

Some small gaps can work, for example the grid on these sawdust screens used on the McCulloch 10 Series saws.

Parts that can be printed flat on the build surface are pretty easy.

Some parts require an elaborate system of supports to obtain good results. This airbox cover for the 300 Series McCulloch saws must be printed at about a 45° angle to align the "grain" in an appropriate direction so the finished part has acceptable strength.

All of that support under the piece is pealed off and thrown away.

There are other types of printers out there, and some with much greater capabilities that what I have but I have been able to turn out a number of decent parts with what I have.

Mark

- Local time

- 9:01 PM

- User ID

- 28351

- Joined

- Jan 22, 2024

- Messages

- 91

- Reaction score

- 685

- Location

- Washington

- Local time

- 11:01 PM

- User ID

- 714

- Joined

- Jan 28, 2016

- Messages

- 4,082

- Reaction score

- 29,103

- Location

- Dike, Iowa

I don't make the drawings...I have an engineer friend that creates the drawings for me and gives them to me in the form of an .STL file. I can manipulate some areas by adjusting the scale in 1, 2, or 3 dimensions but some changes require his adjusting the drawing.

The printer software generates the g-code and I can go in and make changes once the files are saved, but it is often easier to just reload the part (drawing) and create a new printer profile/g-code if a change is needed.

Mark

The printer software generates the g-code and I can go in and make changes once the files are saved, but it is often easier to just reload the part (drawing) and create a new printer profile/g-code if a change is needed.

Mark

Mig_Selv

Well-Known OPE Member

- Local time

- 6:01 AM

- User ID

- 30558

- Joined

- Nov 22, 2024

- Messages

- 55

- Reaction score

- 131

- Location

- The Arctic Circle

The only reasonably viable solution, is to use a 3D scanner. They're relatively cheap and accurate today.

That way you can take your broken part, superglue it back together, and print a spare, within a reasonable time frame.

I do a lot of SLS, which is really nice and high precision, but that's way too expensive for this kind of stuff.

That way you can take your broken part, superglue it back together, and print a spare, within a reasonable time frame.

I do a lot of SLS, which is really nice and high precision, but that's way too expensive for this kind of stuff.

- Local time

- 11:01 PM

- User ID

- 2807

- Joined

- Mar 14, 2017

- Messages

- 6,326

- Reaction score

- 16,455

- Location

- Illinois

I would love to hear moreThe only reasonably viable solution, is to use a 3D scanner. They're relatively cheap and accurate today.

That way you can take your broken part, superglue it back together, and print a spare, within a reasonable time frame.

I do a lot of SLS, which is really nice and high precision, but that's way too expensive for this kind of stuff.

Mig_Selv

Well-Known OPE Member

- Local time

- 6:01 AM

- User ID

- 30558

- Joined

- Nov 22, 2024

- Messages

- 55

- Reaction score

- 131

- Location

- The Arctic Circle

This would be one of the relatively cheap and tested 3D scanners:

There are lots of other options, some significantly cheaper. It depends what you want to do, and how big it can be.

There are lots of other options, some significantly cheaper. It depends what you want to do, and how big it can be.

SimonHS

Pinnacle OPE Member

- Local time

- 5:01 AM

- User ID

- 14420

- Joined

- Nov 4, 2020

- Messages

- 424

- Reaction score

- 1,814

- Location

- Yorkshire, England

What program or file format is most used today for machining. Years ago it was g code.

It's still g code.

Beginners Guide to 3D Printing G-Code Commands | Simplify3D

This guide covers the 10 most common G-Code commands used in 3D printing. Learn what each command does & view examples that you can test on your own 3D printer.

The slicing software generates the g code for you. There are lots of slicers to choose from.

For 3D modelling I use an old release of Solidworks. Damn expensive to buy though. You can try it free for 100 hours I think.

Mig_Selv

Well-Known OPE Member

- Local time

- 6:01 AM

- User ID

- 30558

- Joined

- Nov 22, 2024

- Messages

- 55

- Reaction score

- 131

- Location

- The Arctic Circle

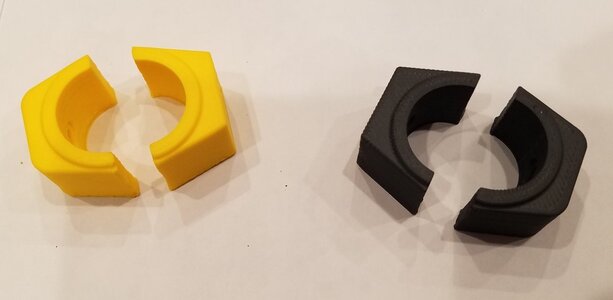

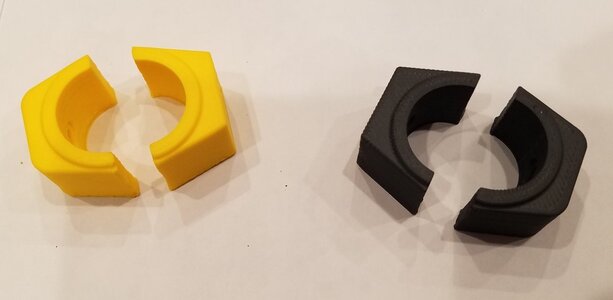

Those you will have a hard time 3D printing, as roundness is not so easy to achieve.

You'll at least have to machine them as well.

You'll at least have to machine them as well.

- Local time

- 11:01 PM

- User ID

- 2807

- Joined

- Mar 14, 2017

- Messages

- 6,326

- Reaction score

- 16,455

- Location

- Illinois

All the machine shops I have talked with the last 25 years say they cannot be machined. They think they were cast originally. The casting companies I have talked with need a 3-D model. It is a vicious circle.

Similar threads

- Replies

- 22

- Views

- 2K