View attachment 275756

Yes. So a thinner grinding wheel is like using a smaller diameter file.

Again, I have used the 1/8" wheels to sharpen larger pitch chains, but I do this in several passes to create the tooth profile. I prefer using the right size wheels.

A few of the '

mini-grinders' will accept 3/16" wheels. Some of them will, with a little modification for clearance under the cover/guard. Some do not have enough threads on the arbor to fully hold the securing flange nut. A few have stated that they accept 1/4" wheels, but they don't.

A few photos here:

https://opeforum.com/threads/better-quality-forester-grinding-wheels-for-hf-type-grinders.22330/

The 'full-sized' '

clone' grinders usually accept 1/8" - 5/16" wheels, in my experience, but they often come with low quality wheels that do not grind as well as the Oregon, Tecomec, MoleMab wheels.

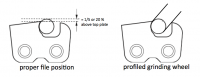

Depends on what you mean by 'outside edge': you should be grinding with the rim / radius of the profiled wheel, not with the flat side.

Philbert