flh69

Well-Known OPE Member

- Local time

- 9:37 PM

- User ID

- 5150

- Joined

- Jan 23, 2018

- Messages

- 142

- Reaction score

- 79

- Location

- Maryland

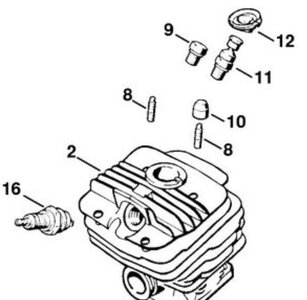

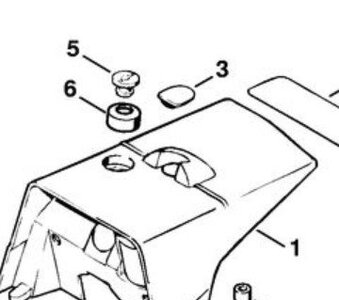

036 Stihl chainsaw bought new years ago. Lately it has become a beast to start. I used to be able to drop start it. But now it will yank the cord out of your when you try to start it. The only way now that I can start it is to place it on the ground with my foot on the handle to hold it down. Pretty hard on this old man’s back I checked the air gap and set it at .011. Checked the starter pawls & cord. I removed the muffler and spark plug and looked inside with a bore scope. The cylinder and piston skirt looks great. There is some carbon on top of the piston but I can not tell how much. Is there anyway to put something in on top of the piston that would dissolve the carbon? I do not want to tear the engine apart.