merc_man

merc_man

- Local time

- 4:52 PM

- User ID

- 933

- Joined

- Feb 24, 2016

- Messages

- 4,952

- Reaction score

- 21,578

- Location

- southern ontario

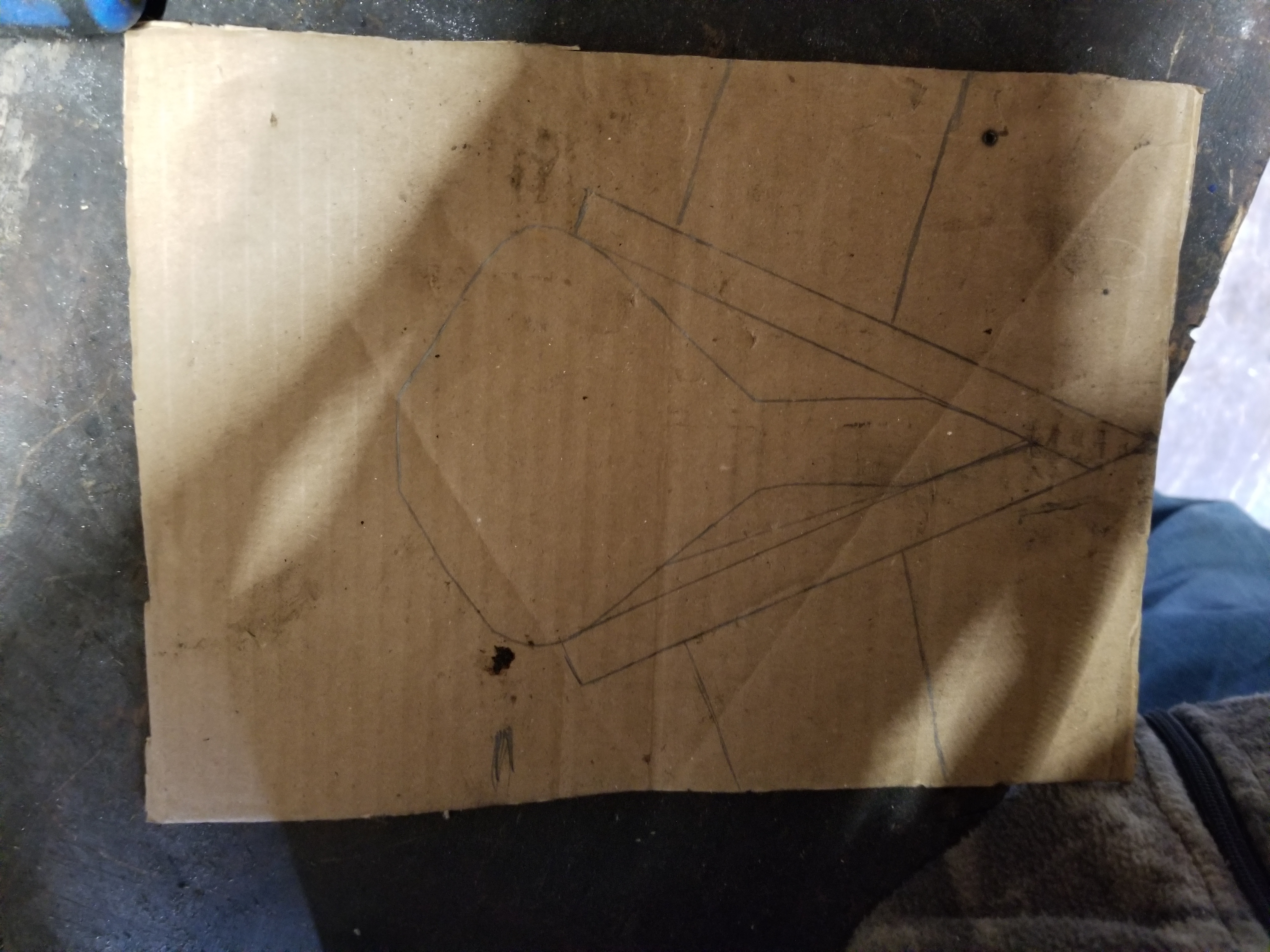

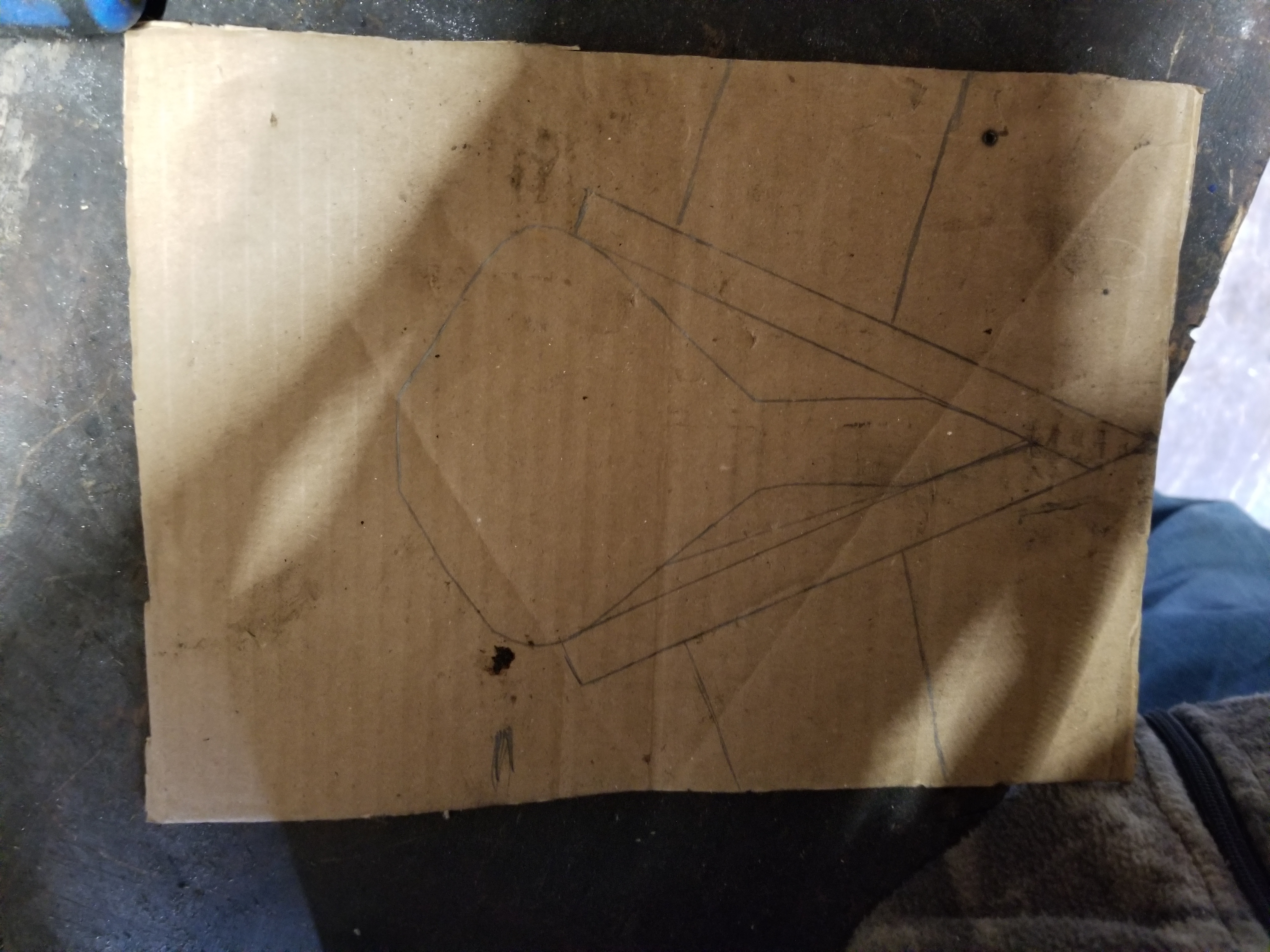

Im starting to make a four way for my champion 22 ton splitter. Wondering who all runs them and what you think of them. They do sell one for mine but reviews are bad on it. I wouldnt buy one anyhow. I enjoy tinkering making stuff.

Heres what i got so far. Its just roughly mocked up and tacked togeather. Front knife will be shortened. Dont need to be that long.

Sent from my SM-G950W using Tapatalk

Heres what i got so far. Its just roughly mocked up and tacked togeather. Front knife will be shortened. Dont need to be that long.

Sent from my SM-G950W using Tapatalk