It's not really necessary to make every cutter equal length.

As long as you have a progressive raker gauge the length of the tooth doesn't matter.

The chains will still cut, but not as smoothly.

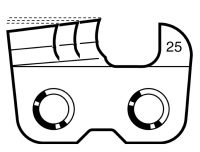

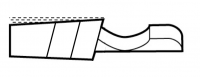

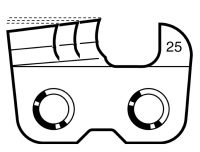

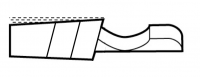

As the cutter gets shorter in

length, it also gets shorter in

height. If adjacent cutters are significantly taller or shorter, the tooth can skip or bounce, which would result in vibration at the 60mph +/- chain speed. Getting all teeth / cutters the same height on any saw is referred to as '

jointing' the teeth.

Same thing with cutting

width, A shorter cutter will produce a narrower

kerf. Again, resulting in less efficient cutting, and possibly, more vibration. Getting all teeth / cutters on a saw to cut the same kerf is referred to as '

setting' the teeth.

Part of the genius of 'modern' saw chain (now 70 years old!) is that a single file stroke can sharpen the scoring cutter (side plate); sharpen the raker (top plate is the

real chip raker); joint and set the tooth. Each step used to take forever on older crosscut saws and scratcher chains, and required much more skill.

Well for me it is easier to get each tooth the same then each depth guage off each individual tooth. With all teeth the same length I just have to check a couple depth gauges then hit each one.

Grinding efficiency is much easier when each tooth is the same. 'Progressive' setting of individual depth gauges is easier when hand filing each cutter individually. As with

@CoreyB, many of the chains that I rehab on the grinder also need more than a 'touch up' sharpening. Many also need to be 'evened up' after some less than professional hand filing - cutter angles and lengths can vary quite a bit, and this brings them back to a more consistent chain.

If a customer comes in with a chain with 90% cutter length but one cutter is 30%, then chopping down all cutters to 30% to make sharpening easier cost the customer 60% of the value of the chain.

My 'customers' are mostly non-profit groups that I volunteer with, or friends. I try to maximize the life of their chains. If 1 or 2 cutters are much shorter (say they hit something), I grind those back and sharpen them separately, and let them 'ride' until the rest of the cutters catch up. If the cutters are all over the place, due to careless filing, or if all of the Right side cutters are different than all of the Left side cutters (not uncommon), then the chain needs 'special attention'.

Philbert