Alaskanrocket

Well-Known OPE Member

Hey guys,

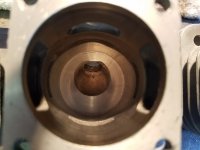

Been messing with a 260 for awhile, pulled the base gasket out for .017 squish, put a tank through it, ran decent. Pulled it apart and found the piston had been making contact with the edge of the squish ring. Looks like it was running rich anyways. My timing numbers are

Ex-99

In-74

Xfer-117

I’m looking for any insights as to what I should do? I’m thinking taking the squish band down some and taking some off the base? Can I get my timing better? Thanks everyone!

Been messing with a 260 for awhile, pulled the base gasket out for .017 squish, put a tank through it, ran decent. Pulled it apart and found the piston had been making contact with the edge of the squish ring. Looks like it was running rich anyways. My timing numbers are

Ex-99

In-74

Xfer-117

I’m looking for any insights as to what I should do? I’m thinking taking the squish band down some and taking some off the base? Can I get my timing better? Thanks everyone!