afleetcommand

Pinnacle OPE Member

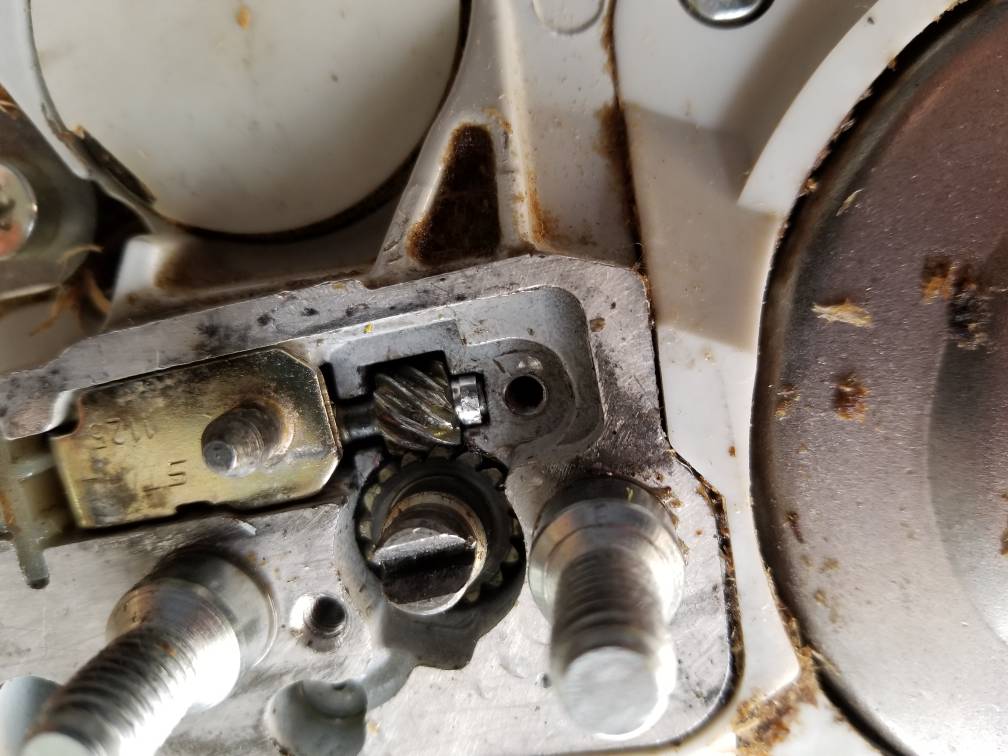

Yup used brass tubing to shim the one end...even works with the farmertec adjusters

@afleetcommandIn that last video i did on them again I think

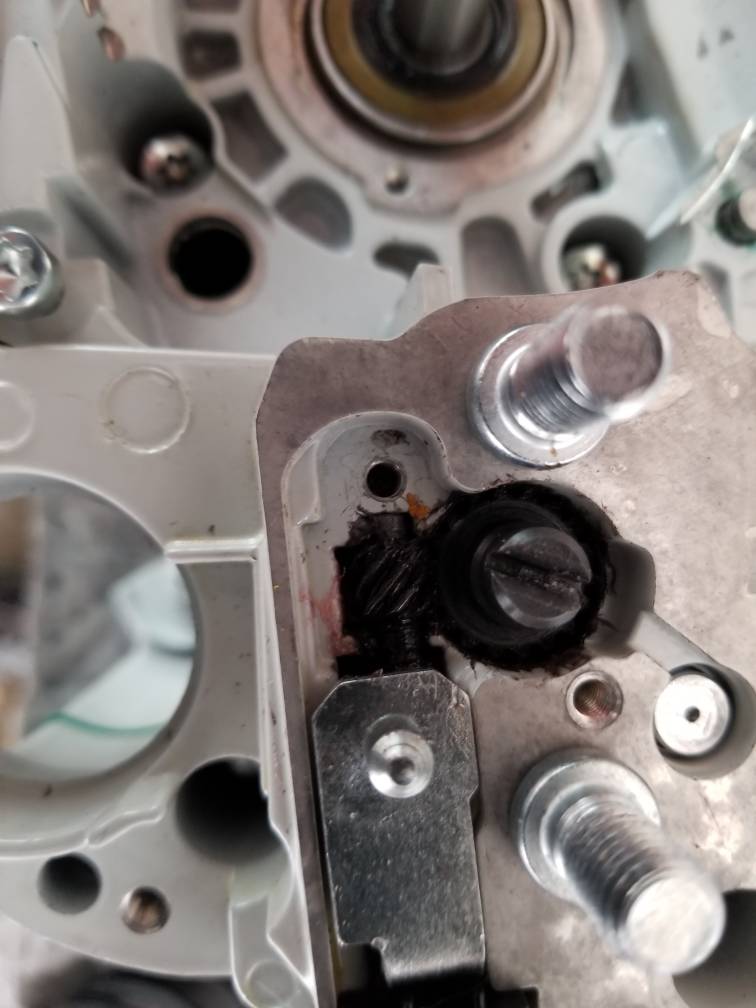

Why post all of this? It's my nature not to just say junk.. it's the "Why is it not working." Knowing a few things to check show what may be adjusted quickly and easily for others in the future building these saws. I honestly think if I had the technology to build an offset shim, the kit provided adjuster may could be made to work.

Again I would love to hear from Walt / AFleetCommand why the Hyway adjuster did NOT work in his last saw build? The video glossed right over that.

I have also been made aware there is a bulletin from Stihl that discusses a running change in these adjusters on the OEM side. That also may be part of the root issue with the cloning. Just like the 034Super cylinders included with MS360 muffler in those parts kits. Same family but not quiet compatible.

Sent from my SM-G955U using Tapatalk

Thanks Jimmy! I too like to understand the why and how. Thanks for showing this. Now I know what to look for when I open my China saws.

Sent from my iPhone using Tapatalk

I read a bunch of these threads.. way more than I post. I almost get a sense of hostility at points from people expecting a $250 saw kit to go smoothly; they wont! I used this 066 kit for a long time for just what it was intended for, a complete parts kit! People would call and I'd have parts on hand. I'd order a replacement part and pitch it back in the box. It was handy as hell and kept customers happy.

Growing up in a shop, dealing with high performance motors, I've seen some motors work damn good and some with the same specs be so-so. It all had to deal with cumulative error and which end of tolerances things fell on. These kit saws are a perfect example of those situations.

I want to see how these play out. Instead of calling them garbage, if one can work through and understand the problems, correcting them may be easy. From there you can decide do you want to work through those problems OR buy and OEM and deal with the damage that's been inflicted on it. For me to buy a used OEM MS660 I'd plan on $300-400. Add in a full rebuild, anything else that's beat up.. I can quickly end up at over $600 into a saw. These kits, maybe $150-200 less total after built and tweaks worked through, but it looks nice, I do not spend half a day cleaning and degreasing parts, and I think I have this one running better than the OEM saws right now. Will it hold up? I don't know. I do not plan to use it everyday. Will I ever get the chain tensioner silky smooth? Probably not. Can I work within it's limits for the 3-4 times a year I'll fire this up? You bet I can.

I'll update as I play with the tensioners more. I'm also still curious to other's experiences if you have explored. Someone like Walt have been through more of these kits than I will ever do. They have working knowledge that is priceless.

I like your take on this whole situation. I fully agreeI read a bunch of these threads.. way more than I post. I almost get a sense of hostility at points from people expecting a $250 saw kit to go smoothly; they wont! I used this 066 kit for a long time for just what it was intended for, a complete parts kit! People would call and I'd have parts on hand. I'd order a replacement part and pitch it back in the box. It was handy as hell and kept customers happy.

Growing up in a shop, dealing with high performance motors, I've seen some motors work damn good and some with the same specs be so-so. It all had to deal with cumulative error and which end of tolerances things fell on. These kit saws are a perfect example of those situations.

I want to see how these play out. Instead of calling them garbage, if one can work through and understand the problems, correcting them may be easy. From there you can decide do you want to work through those problems OR buy and OEM and deal with the damage that's been inflicted on it. For me to buy a used OEM MS660 I'd plan on $300-400. Add in a full rebuild, anything else that's beat up.. I can quickly end up at over $600 into a saw. These kits, maybe $150-200 less total after built and tweaks worked through, but it looks nice, I do not spend half a day cleaning and degreasing parts, and I think I have this one running better than the OEM saws right now. Will it hold up? I don't know. I do not plan to use it everyday. Will I ever get the chain tensioner silky smooth? Probably not. Can I work within it's limits for the 3-4 times a year I'll fire this up? You bet I can.

I'll update as I play with the tensioners more. I'm also still curious to other's experiences if you have explored. Someone like Walt have been through more of these kits than I will ever do. They have working knowledge that is priceless.

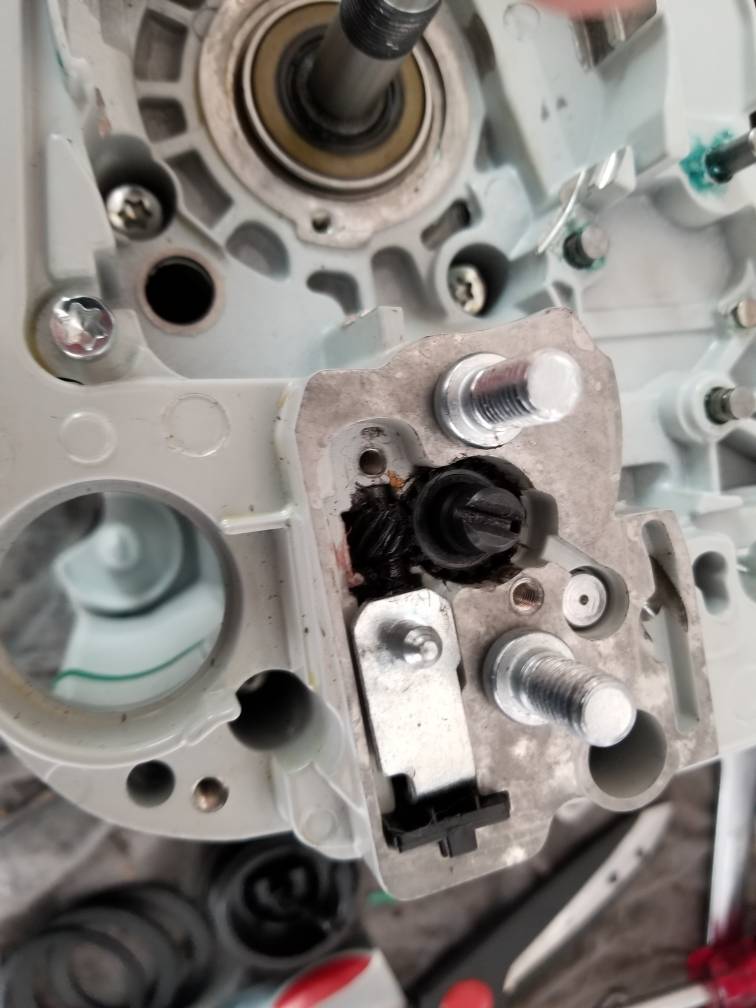

Where did you have to hog out the case?I had some trouble with all the bar adjusters on the Asian 660s.

The first one I just ripped one out of a MS460 and it worked fine.

For the next two, I ordered some from HL Supply. They seemed to be of better quality, and smoother to operate (not installed), but would not work when installed in the Asian 660. Was not sure if the spacing of the Asian 660 was the same as stock, so I did not blame the HL parts.

Just hogged out the case on both saws and got the Asian adjusters that came with the saw to work. They do seem to improve with use.