spencerdiesel

Well-Known OPE Member

- Local time

- 6:02 AM

- User ID

- 14124

- Joined

- Oct 10, 2020

- Messages

- 98

- Reaction score

- 164

- Location

- Brevard, NC

Hi all, just put a new OEM Husqvarna cyl and piston on my new to me 346xp. I bought the saw with an AM top end and chicom carb.

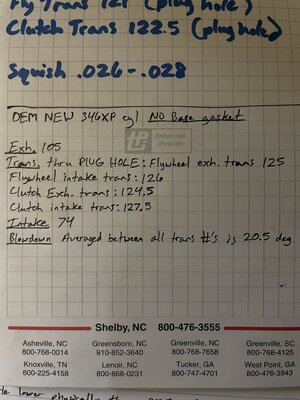

As I am dabbling in port timing and such I put the wheel on and checked stock port times on the new OEM jug for curiosity.

I first checked transfers with a light shining through exhaust port and looking into the plug hole.

I then checked transfers using the right method of pushing the ring into the bore with the piston until it was at the top of the transfers. The discrepancy is huge between methods, but just based on what most 346s run for trans height, I just can’t believe the numbers I got from checking with the ring?

The “looking through the plug hole method got numbers very much what I would have expected for a stock 346.

Both methods gave repeatable and consistent results. Pay no mind to the blue writing, that was the AM top end.

Using the ring method I repeatedly got 133-134 degrees for transfers???

Also after a good hard break in I noticed the was more wash from the flywheel side trans than the clutch side. Is that due to the fly side trans opening a degree or two sooner and “venting” the majority of pressurized mix? Of course this is just a point of curiosity for me and I know it’s inconsequential. Thanks y’all!

As I am dabbling in port timing and such I put the wheel on and checked stock port times on the new OEM jug for curiosity.

I first checked transfers with a light shining through exhaust port and looking into the plug hole.

I then checked transfers using the right method of pushing the ring into the bore with the piston until it was at the top of the transfers. The discrepancy is huge between methods, but just based on what most 346s run for trans height, I just can’t believe the numbers I got from checking with the ring?

The “looking through the plug hole method got numbers very much what I would have expected for a stock 346.

Both methods gave repeatable and consistent results. Pay no mind to the blue writing, that was the AM top end.

Using the ring method I repeatedly got 133-134 degrees for transfers???

Also after a good hard break in I noticed the was more wash from the flywheel side trans than the clutch side. Is that due to the fly side trans opening a degree or two sooner and “venting” the majority of pressurized mix? Of course this is just a point of curiosity for me and I know it’s inconsequential. Thanks y’all!

Attachments

Last edited: