- Local time

- 1:13 PM

- User ID

- 21

- Joined

- Dec 4, 2015

- Messages

- 5,336

- Reaction score

- 28,488

- Location

- In a meeting

Spoken from true book experience

You must know better ,then .

Spoken from true book experience

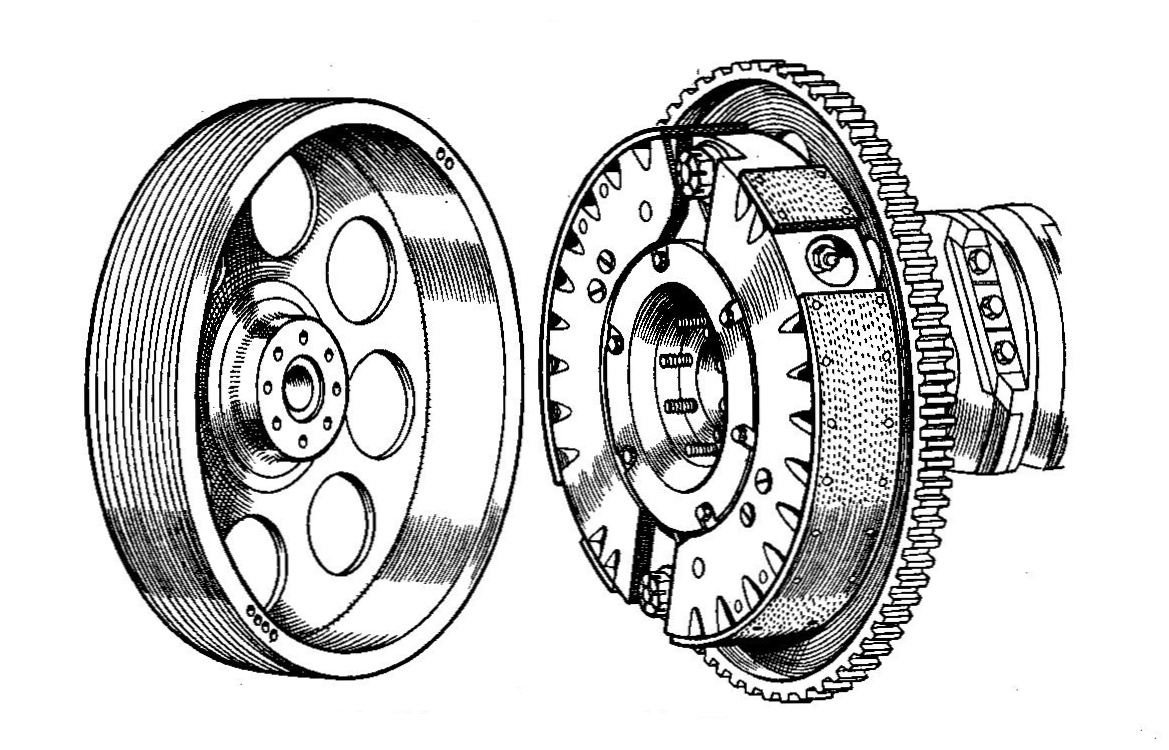

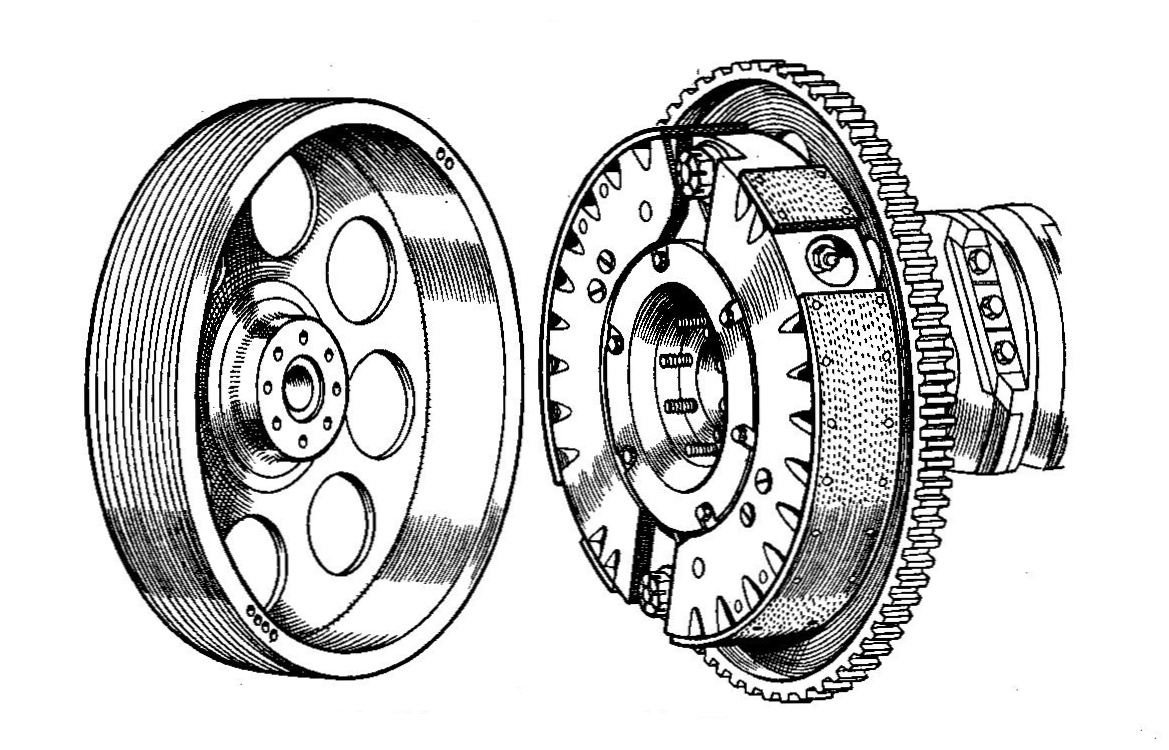

Stihl clutches are a bit more robust than Husqvarna ones ,but still the static friction that prevents the clutch shoes slipping from the drumWhat are the thoughts on running the Stihl 4mix engines at partial throttle?

Do you even own a combi-system ?Stihl clutches are a bit more robust than Husqvarna ones ,but still the static friction that prevents the clutch shoes slipping from the drum

depends on the square of angular velocity ( rpm ) .

Two times more rpms ,means four times greater clutch static friction .

Three times more rpms ,means nine times more clutch static friction .

{ As a side note which applies to chainsaws only ,where there's an amount of debris ( powdered wood & bar/chain oil ) which acts as a light lubricant between clutch drum/sprocket and clutch shoes :

The static friction coefficient ( μ ) of a dry and clean clutch is about three times higher than the static

friction coefficient of a dirty clutch

( μ Clean min = 0.74 vs μ Dirty max = 0.23 ) .

A clean clutch needs -at least - three times the force needed for a dirty clutch to slip . }

Have witnessed plenty of times the premature clutch wear ,because the operator thought that WOT was not needed /was an "overkill"/was "scary"/ was loud (!) /was fuel wasting /was this /was that .

Yet , the "Top of the top" remains the "for less clutch wear" !

Go figure ..

I'm not sure what kind of carbs the Stihl 4-mix have .If the carb has just

a single main jet ,then it's not designed to be operated at any other position than : A ) Idle & B ) WOT .

At any other throttle position than idle or WOT ,

the gasoline entering into the venturi is supplied by the idle jet and the acceleration jet(s) or the acceleration pump .

The mixture tends to get lean and a

prolonged period of such operation will induce a gradual wear on the piston skirts ,piston rings and cylinder wall .

It won't fry or "instantly kill" the engine but for sure will "steal away " plenty of time from it's service life .

A bit of wikipedia fun :

Centrifugal clutch - Wikipedia

en.m.wikipedia.org

Centrifugal force - Wikipedia

en.m.wikipedia.org

( read "Dry friction" )

Friction - Wikipedia

en.m.wikipedia.org

Used to. But sold the whole set .Do you even own a combi-system ?

You seem to know everything and being quick to jump into conclusions .Figures, because I have both, and very rarely do I ever have to use full throttle unless I’m using the modified 16” polesaw. Using everything else, it’s part throttle due to no to little load. And when NOT under full load, the machine is blubbering like a rented hoe, rich, rich, rich …….. no worries about the clutch and very obvious audible feedback about how fat she’s running.

Your “concerns” and answers are textbook, little to no experience/understanding about the actual environment the machine is being used in.

Good luck to you with your endeavors of being a keyboard warrior here at OPE, I for one, certainly see right through you.