Brewz

Free Range Human in a Tax Farm

- Local time

- 2:32 AM

- User ID

- 550

- Joined

- Jan 16, 2016

- Messages

- 4,217

- Reaction score

- 14,308

- Location

- Hunter Valley - Australia

Hi Folks

My journey begins here and without a lathe, as most of we chainsaw enthusiasts are, I need to do the work by hand accurately and precisely.

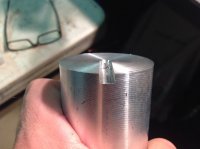

Now i have had some help from a lather with a 54mm mandrel cut to fit snug inside an 066 cylinder.

I also have bought a 1/2" HHS cutting bit.

I am after any advice on how to set this up properly to get it cutting a nice squish band.

I can then sand the base to get my squish back. I dont care if I need to spend weeks doing it for my own saws as long as I get best results.

I have it im my head on how to fit it up but would like this to become an info thread for amyone ging forward on how to do it propery.

My journey begins here and without a lathe, as most of we chainsaw enthusiasts are, I need to do the work by hand accurately and precisely.

Now i have had some help from a lather with a 54mm mandrel cut to fit snug inside an 066 cylinder.

I also have bought a 1/2" HHS cutting bit.

I am after any advice on how to set this up properly to get it cutting a nice squish band.

I can then sand the base to get my squish back. I dont care if I need to spend weeks doing it for my own saws as long as I get best results.

I have it im my head on how to fit it up but would like this to become an info thread for amyone ging forward on how to do it propery.