BlackCoffin

Pinnacle OPE Member

- Local time

- 6:59 AM

- User ID

- 11676

- Joined

- Feb 6, 2020

- Messages

- 421

- Reaction score

- 2,400

- Location

- Washington

While milling a 60” log recently, and it being the largest I’ve done yet, I noticed the mill flexing as I came out of the log. Using 2 guys despite how much we tried I kept getting a wing on one side of the log. I’ve never had this happen on smaller logs, and my only guess is the mill being spread almost all the way out the rails are flexing along with the 72” bar when trying to swing out of the log my usual way.

I’ve seen other setups with multiple supports along the rail as it gets wide, the same supports that the height adjustment posts are attached to. So I figured I’d just build my own to bolt in as I start extending my mill out for larger logs.

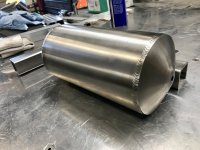

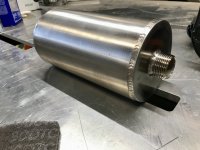

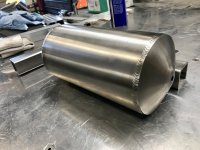

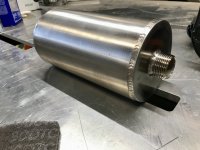

I also decided after that I could an auxiliary oiler setup. I got some stainless 4.5” pipe off the scrap pile at work. I think cut out a disc and pressed it with a 3/4” nut in the center with the outside supported by a similar size piece of pipe. Doing this made a cone that will scavenge the oil to the center. I drilled and tapped the center for 1/8”npt and will mount a valve there.The top I cut a piece to fit the top and used a hole saw to get the hole in the center for a 1” nipple to weld in. The end goal will have a rigid line going from the tank and down to the chainsaw bar. Will update progress as I go.

I’ve seen other setups with multiple supports along the rail as it gets wide, the same supports that the height adjustment posts are attached to. So I figured I’d just build my own to bolt in as I start extending my mill out for larger logs.

I also decided after that I could an auxiliary oiler setup. I got some stainless 4.5” pipe off the scrap pile at work. I think cut out a disc and pressed it with a 3/4” nut in the center with the outside supported by a similar size piece of pipe. Doing this made a cone that will scavenge the oil to the center. I drilled and tapped the center for 1/8”npt and will mount a valve there.The top I cut a piece to fit the top and used a hole saw to get the hole in the center for a 1” nipple to weld in. The end goal will have a rigid line going from the tank and down to the chainsaw bar. Will update progress as I go.