You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Echo 490 to ported 4910…to cs-5484

- Thread starter Ketchup

- Start date

Dolkitafreak

Dolkita686

- Local time

- 5:30 AM

- User ID

- 7904

- Joined

- Nov 19, 2018

- Messages

- 540

- Reaction score

- 1,795

- Location

- Central Ohio

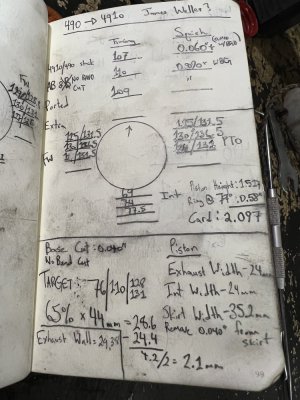

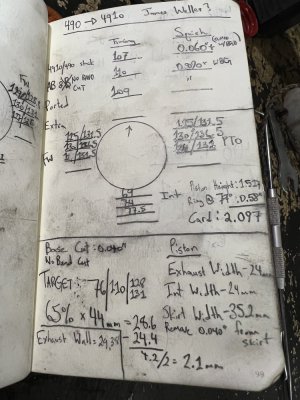

Curious to see how it does. I wanna see comp too, mine is 190 with base cut and 102. Nice clean work.Well those numbers are higher than mine, but it’s good to know if I go back in.

View attachment 364682

View attachment 364683

View attachment 364684

Currently 108/126-130/73. I’ll take the intake to 76 after dinner.

farminkarman

I like the red & black ones

- Local time

- 4:30 AM

- User ID

- 13535

- Joined

- Aug 17, 2020

- Messages

- 5,027

- Reaction score

- 29,062

- Location

- Neenah Wisconsin

Ketchup

Epoxy member

- Local time

- 3:30 AM

- User ID

- 5594

- Joined

- Mar 12, 2018

- Messages

- 2,517

- Reaction score

- 8,473

- Location

- Colorado

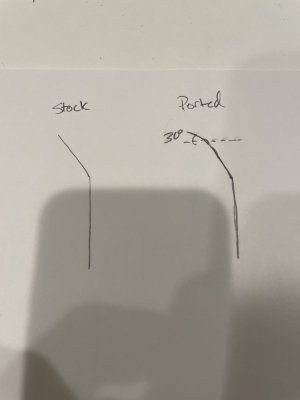

That’s what I did too. Hard to see in the photos. I just felt like the angle was too sharp.I’m not suggesting it is a better approach, but on the one I built, I flattened the roof of the secondaries to about a 30 degree angle. I only carried this into the port from the plating about 3/8”.

Dolkitafreak

Dolkita686

- Local time

- 5:30 AM

- User ID

- 7904

- Joined

- Nov 19, 2018

- Messages

- 540

- Reaction score

- 1,795

- Location

- Central Ohio

I also think the ramp creates a pinch point between cylinder wall and ramp. Curious to see how yours does now!That’s what I did too. Hard to see in the photos. I just felt like the angle was too sharp.

I normally go with 65% as well.Anybody know their exhaust width? Mine is 28.6mm (65% of bore).

- Local time

- 5:30 AM

- User ID

- 319

- Joined

- Dec 29, 2015

- Messages

- 9,643

- Reaction score

- 63,593

- Location

- Strong Island NY

If you want that base extended, its far enough from the bore to weld without warping the bore. You’d just have to spin it flat again.Since I had a 346 jug down to look at…

View attachment 364603

View attachment 364604

The case would need clearance work to drop the the 346 jug onto the 490 case but it looks doable.

The bolt pattern is the real problem. The upper right corner in the photo would be stretched beyond the edge of the base.

Another problem is the wrist pin bearing. 346 is 10mmIDx14mmOD. 490 is 11mmx15mm. Not sure how hard it would be to find a 10mmx15mm in the same length.

Better get grinding.

Piston Skirt

Super OPE Member

- Local time

- 12:30 PM

- User ID

- 5990

- Joined

- Apr 25, 2018

- Messages

- 198

- Reaction score

- 665

- Location

- Europe

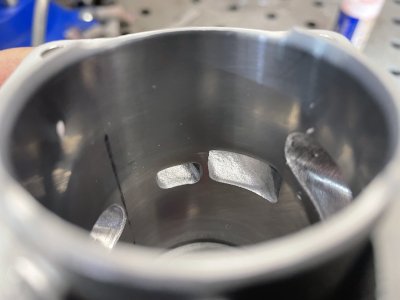

Edit: Something I hadn’t thought of until just now: that port may have been carved by some sort of machine like a cnc. Maybe the cutter head couldn’t reach that corner perfectly.

It is not a mistake and that bit there is left by a reason.

The ports are cut very precisely, using electric discharge method.

In case you'd still think it's production limitations - that very method is used on some other ECHO engines and the little protruding bits are not there

Ketchup

Epoxy member

- Local time

- 3:30 AM

- User ID

- 5594

- Joined

- Mar 12, 2018

- Messages

- 2,517

- Reaction score

- 8,473

- Location

- Colorado

That’s very practical. Tempted to even mine out. How do you get the squish down without your timing being low? Maybe my 490 piston is 0.020” shorter? I was at 0.060” squish stock with the 490 piston and gasket. I dropped the base 0.040” and my numbers were 110/130-136 (maybe a tad lower, I had a hard time reading them).View attachment 364692

That is normally how I do the uppers

I normally go with 65% as well.

Well then I guess I better push it to 70%. Not much point of trying the 490 piston if I port it the same as the 4910. I don’t have a windowed piston to compare. Not sure how much skirt width it has.

Dolkitafreak

Dolkita686

- Local time

- 5:30 AM

- User ID

- 7904

- Joined

- Nov 19, 2018

- Messages

- 540

- Reaction score

- 1,795

- Location

- Central Ohio

Nope those numbers are about right for 4910, 490 piston has same specs. I haven’t found a good power gain widening exhaust on these. The gain of 490 should be in the fact that you’re eliminating the unneeded windows. Slab the sides off the 490 slug at the bottomThat’s very practical. Tempted to even mine out. How do you get the squish down without your timing being low? Maybe my 490 piston is 0.020” shorter? I was at 0.060” squish stock with the 490 piston and gasket. I dropped the base 0.040” and my numbers were 110/130-136 (maybe a tad lower, I had a hard time reading them).

Well then I guess I better push it to 70%. Not much point of trying the 490 piston if I port it the same as the 4910. I don’t have a windowed piston to compare. Not sure how much skirt width it has.

Ketchup

Epoxy member

- Local time

- 3:30 AM

- User ID

- 5594

- Joined

- Mar 12, 2018

- Messages

- 2,517

- Reaction score

- 8,473

- Location

- Colorado

Well there’s certainly room for improvement but I think I’ll button it up and see how it runs.

I flared the base of the intake and matched it to the boot. I would have widened the whole thing but the bottom ring land is right off the PTO side of the port. I trimmed 0.040” of the 490 piston skirt in stead of dropping the port. I had to drop it a touch to get through the plating but I figured a lighter piston is a good thing.

Unfortunately the Exhaust port itself was a limiting factor. The outside of the port is only 29.4mm so you can’t make a straight tunnel that’s 70% of bore. I flared it a good bit on the inside, so hopefully it’s still pretty snappy.

The intake has similar limitations but it’s not as bad. I doubt I need to widen it as much as I did. I just like ports that deliver a lot as soon as they open.

I took a short video running water through the transfers. Definitely still pretty steep angles.

youtube.com

youtube.com

Notes so far:

I flared the base of the intake and matched it to the boot. I would have widened the whole thing but the bottom ring land is right off the PTO side of the port. I trimmed 0.040” of the 490 piston skirt in stead of dropping the port. I had to drop it a touch to get through the plating but I figured a lighter piston is a good thing.

Unfortunately the Exhaust port itself was a limiting factor. The outside of the port is only 29.4mm so you can’t make a straight tunnel that’s 70% of bore. I flared it a good bit on the inside, so hopefully it’s still pretty snappy.

The intake has similar limitations but it’s not as bad. I doubt I need to widen it as much as I did. I just like ports that deliver a lot as soon as they open.

I took a short video running water through the transfers. Definitely still pretty steep angles.

Ported 4910 transfer flow

Notes so far:

Ketchup

Epoxy member

- Local time

- 3:30 AM

- User ID

- 5594

- Joined

- Mar 12, 2018

- Messages

- 2,517

- Reaction score

- 8,473

- Location

- Colorado

First impressions…

I don’t like it. Feels like a homeowner saw, sounds like a homeowner saw. It has enough power, but no extra. Not fast enough, only kind of snappy. Antivibe isn’t great. Filling the oil tank is irritating.

I think the coil is limited. Hard to tell because it sounds like an old lady farting in church, but I think I was hitting it. High needle is 2-1/4 turns out at 9400’. Noodles fair with 18” .325 but jams because the clutch cover can’t clear the noodles.

I bothered to put a de-comp in it. What a joke. It might be blowing 170. Maybe.

To be fair, it probably needs a new air filter and rings. It did seem to be waking up a bit as I ran it longer.

So I’ll take it to work and get a few tanks through it. Maybe make a video. If it stays like it is, I’ll go back in. Even out the transfers, raise the exhaust and transfers 3 degrees, swap in new rings. Maybe add a second muffler port. But it’s got a long way to go. I doubt I’ll ever like it.

Deeply underwhelming.

I don’t like it. Feels like a homeowner saw, sounds like a homeowner saw. It has enough power, but no extra. Not fast enough, only kind of snappy. Antivibe isn’t great. Filling the oil tank is irritating.

I think the coil is limited. Hard to tell because it sounds like an old lady farting in church, but I think I was hitting it. High needle is 2-1/4 turns out at 9400’. Noodles fair with 18” .325 but jams because the clutch cover can’t clear the noodles.

I bothered to put a de-comp in it. What a joke. It might be blowing 170. Maybe.

To be fair, it probably needs a new air filter and rings. It did seem to be waking up a bit as I ran it longer.

So I’ll take it to work and get a few tanks through it. Maybe make a video. If it stays like it is, I’ll go back in. Even out the transfers, raise the exhaust and transfers 3 degrees, swap in new rings. Maybe add a second muffler port. But it’s got a long way to go. I doubt I’ll ever like it.

Deeply underwhelming.

Dolkitafreak

Dolkita686

- Local time

- 5:30 AM

- User ID

- 7904

- Joined

- Nov 19, 2018

- Messages

- 540

- Reaction score

- 1,795

- Location

- Central Ohio

Nice thread!First impressions…

I don’t like it. Feels like a homeowner saw, sounds like a homeowner saw. It has enough power, but no extra. Not fast enough, only kind of snappy. Antivibe isn’t great. Filling the oil tank is irritating.

I think the coil is limited. Hard to tell because it sounds like an old lady farting in church, but I think I was hitting it. High needle is 2-1/4 turns out at 9400’. Noodles fair with 18” .325 but jams because the clutch cover can’t clear the noodles.

I bothered to put a de-comp in it. What a joke. It might be blowing 170. Maybe.

To be fair, it probably needs a new air filter and rings. It did seem to be waking up a bit as I ran it longer.

So I’ll take it to work and get a few tanks through it. Maybe make a video. If it stays like it is, I’ll go back in. Even out the transfers, raise the exhaust and transfers 3 degrees, swap in new rings. Maybe add a second muffler port. But it’s got a long way to go. I doubt I’ll ever like it.

Deeply underwhelming.

490 coil is limited, 4910 isn’t.

Ketchup

Epoxy member

- Local time

- 3:30 AM

- User ID

- 5594

- Joined

- Mar 12, 2018

- Messages

- 2,517

- Reaction score

- 8,473

- Location

- Colorado

- YouTube

Enjoy the videos and music you love, upload original content, and share it all with friends, family, and the world on YouTube.

Ran better 4000’ lower, but still not great. Couldn’t quite keep up with a stock 261. At current power it feels a lot more like a ported 40cc saw and kind of peaky and irregular. I’m going back in.

Thinking I’ll take the primary to 124 and raise the exhaust to 105. Open to suggestions.

Ford3000

Super OPE Member

Here are some mods and dyno runs from joe, the shindaiwa is the same saw as the echo 490,

might glean some info from looking at the cylinders, as far as I remember the 4910

gained the most, followed by the 501p then the 490 / shindaiwa.

www.youtube.com

www.youtube.com

might glean some info from looking at the cylinders, as far as I remember the 4910

gained the most, followed by the 501p then the 490 / shindaiwa.

- YouTube

Enjoy the videos and music you love, upload original content, and share it all with friends, family, and the world on YouTube.

Similar threads

- Replies

- 6

- Views

- 1K

- Replies

- 51

- Views

- 8K