- Local time

- 3:20 PM

- User ID

- 2014

- Joined

- Oct 21, 2016

- Messages

- 34,603

- Reaction score

- 147,161

- Location

- Kansas

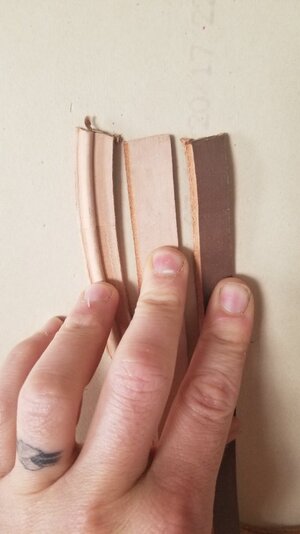

So in the last few years I've started a new hobby that I can say saves me money, cobbling. So here is a pair of boots I'm reworking. Now with no machines and limited free time this is a slow going process.

I'm also keen on doing things like this to diminish the throw away ideas that have been all the "rage" these days.

Also good boots are like pro grade chainsaws, easier to fix.

So what we have here is a pair of RW 2213.

I'm also keen on doing things like this to diminish the throw away ideas that have been all the "rage" these days.

Also good boots are like pro grade chainsaws, easier to fix.

So what we have here is a pair of RW 2213.

Last edited: